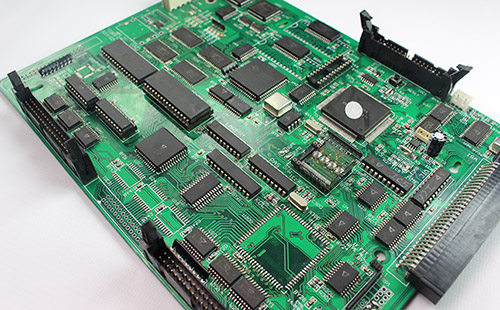

DetaiLED explanation of PCBA chip technology standard

1、 Quality Inspection Standard for PCBA patch

The PCBA chip quality inspection standard, also known as the PCBA appearance inspection standard (IPC-A-610), is a global electronic assembly standard. The latest version is IPC-A-610F. The quality inspection standard defines the evaluation standard and defects of welding quality, guides the PCBA processing process, and is the most basIC quality inspection standard in electronic processing plants.

1. Definition of standards

[Accept Criterion]: The acceptance criteria include ideal conditions, acceptance conditions and rejection conditions.

Target Condition: This assembly situation is close to the ideal and perfect assembly result. It has good assembly reliability and is judged as ideal.

[Accept Condition]: This assembly condition is not in line with the ideal condition, but it can maintain the assembly reliability, so it is regarded as qualified and judged as acceptable.

Reject Condition: This assembly condition fails to meet the standard, which may affect the functionality of the product. However, based on the appearance factors to maintain the competitiveness of the company's products, it is determined as a rejection condition.

2. DEFINITION OF DEFECTS

[Critical Defect]: refers to a defect that can cause injury to human body or machine, or endanger the safety of life and property. It is called a fatal defect, and is represented by CR.

[Major Defect]: it refers to the defect that has lost the practicality or reduced the reliability of the product in terms of its substantial function. Product damage and poor function are called major defects, which are represented by MA.

[Minor Defect]: refers to the service performance of a unit defect, which does not substantially reduce its usefulness, but can still achieve the desired purpose. Generally, it is the difference in appearance or mechanism assembly, expressed in MI.

The quality inspection standard can provide guidance for the operation in the production process and product quality assurance, and has important significance for improving the welding quality.

2、 PCBA Patch Management Specification

PCBA mounting process is relatively complex, and any problem in any link will cause welding quality problems. Therefore, professional management specifications are required in the processing process.

1. Comply with Regulations on Air Shower Room

Wear static clothes and hats according to the specifications, then press the air shower door switch, open the front door of the air shower room and enter the air shower room. Step on the adhesive pad to remove dust first. When the air shower starts, please rotate your body according to the prompts. The number of people entering the air shower room can not exceed 4 at a time. The air shower time in the air shower room is set as 8 seconds, and the user shall not change it at will. After the air shower door is blown, the door will open automatically and it is forbidden to pull the door on both sides by hand. The adhesive dust mat in the air shower room shall be replaced twice a day, and it shall be recorded in the Tear off Record of Adhesive Dust Mat. If it is dirty, it can be replaced at any time to keep it clean.

2. Factory 7S management

The workshop temperature shall be 18-26 ℃ and the humidity shall be 35-75%. The workshop shall be arranged (Seiri), rectified (Seiton), cleaned (Seiso), cleaned (Seiketsu), cultivated (Shitsuke), safe (safety) and saved (save). It can effectively solve the disorder and disorder in the workplace, effectively improve personal action ability and quality, effectively improve the management of documents, data and archives, effectively improve work efficiency and team performance, and make processes SIMple, humanized and standardized.

3. Solder Paste Management Specification

(1) Solder paste storage environment: Refrigeration temperature 0 ℃<T<10 ℃ (T represents the actual temperature), record the refrigerator temperature in the Refrigerator Temperature Record Form every day.

(2) When the new solder paste is put into storage, check whether the outer package is damaged. After the outer package is removed, check whether there is an ice bag inside the incubator package. Visually check whether the solder paste tank is damaged, whether the solder paste package is sealed and whether it is unsealed. (3) Check whether the brand, model and quantity on the solder paste tank are consistent with the receipt, and the difference between the arrival date and the validity period of the solder paste shall not be less than 6 months.

Solder paste storage

(4) If there is any discrepancy in the inspection characteristics, return it to the warehouse and notify the purchaser to contact the manufacturer for return! (5) After the solder paste passes the inspection, this batch of solder paste shall be numbered, and the "Solder Paste Control Label" shall be pasted on the outer wall of the solder paste tank to facilitate tracking control during use! Fill in the Solder Paste Warehousing Record Form

(6) For the placement of new solder pastes, the last batch of solder pastes shall be taken out according to the Solder Paste Management Specifications. The new solder pastes shall be stored in the refrigerator in order according to the number from large to SMAll. The placement principle: each storage space shall be placed from right to left from inside to outside according to the number sequence. Finally, put the remaining solder paste of the last batch on the outside. Solder paste receiving principle: Give priority to the unsealed solder paste, and check whether the solder paste is within the validity period. The application of new solder paste follows the principle of "from left to right, from outside to inside" (the number of solder paste bottle ranges from small to large). After taking out the solder paste, fill in the relevant information such as the temperature return date, time and recorder on the Solder Paste Control Label.

(7) Solder paste receiving: when receiving solder paste, the operator needs to confirm whether the solder paste temperature return time is four hours. The solder paste shall be stirred for 5 minutes at 90% speed. The use of the solder paste mixer shall refer to the Specification for Use of the Solder Paste Mixer

(8) The Solder Paste Receiving Record Form and Solder Paste Control Label shall be filled in when the solder paste is received. The service life of solder paste is 24 hours. If the solder paste is not used for 24 hours, it shall be scrapped and the Solder Paste Scrapping Record Form shall be filled in and signed by technicians or engineers for confirmation.

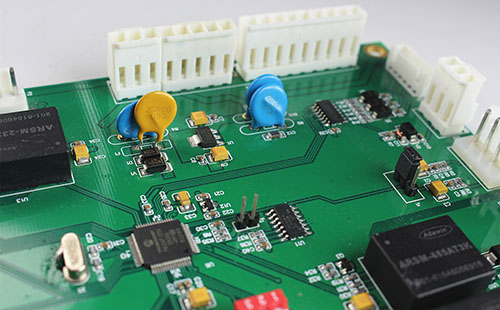

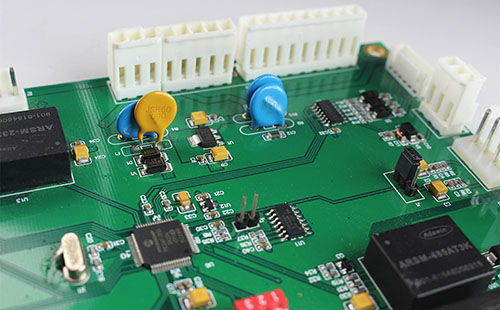

3、 Electrostatic Management Standard for PCBA Patch

In the process of PCBA chip processing, static electricity has always been an important factor causing chip damage. Due to the easy production of static electricity, it is necessary to strictly manage static electricity in electronic processing plants to avoid unnecessary losses to electronIC components.

Static electricity management of PCBA chip

1. Equipment grounding

It is realized by connecting the metal conductor with the grounding device, and introducing the leakage current, static charge and lightning current that may be generated on the electrical equipment and other production equipment into the ground to avoid personal electric shock and possible fire accidents.

2. Wear electrostatic clothes, shoes and bracelets; Electrostatic clothing and shoes shall pass ESD test and be recorded.

3. Clean all sources of static electricity in the work area, such as plastic bags, boxes, foamed plastics or personal items (tea cups, hairpins, paper towels, key pendants, glasses boxes, etc.), and keep them at least 750px away from ESD sensitive elements.

4、 Cleaning standard of PCBA patch

When the solder paste on the PCB is printed with tin, less tin, Wuxi, more tin, and tin tips, or stays on the production line for more than one hour, the PCB needs to be cleaned and reprinted.

PCB cleaning steps:

1. Scrape the solder paste on PCB to the solder paste scrap box with a small scraper

2. Wet the dust-free wiping paper with plate washing water

3. Hold PCB with left hand and wipe PCB surface with dust-free wiping paper with right hand

4. After wiping, use an air gun to dry the PCB, and blow off solder paste that is difficult to clean such as pinholes and screw holes

matters needing attention:

1. Defective PCB must be cleaned within one hour

2. Clean the PCB in the cleaning area, and separate the PCB to be cleaned from the cleaned PCB

3. Make sure that the pinholes, screw holes and other positions are clean.

There are many PCBA patch processing links, and a small factor is easy to cause product defects. Only by implementing strict PCBA patch technical standards can we standardize production and reduce product defects.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱