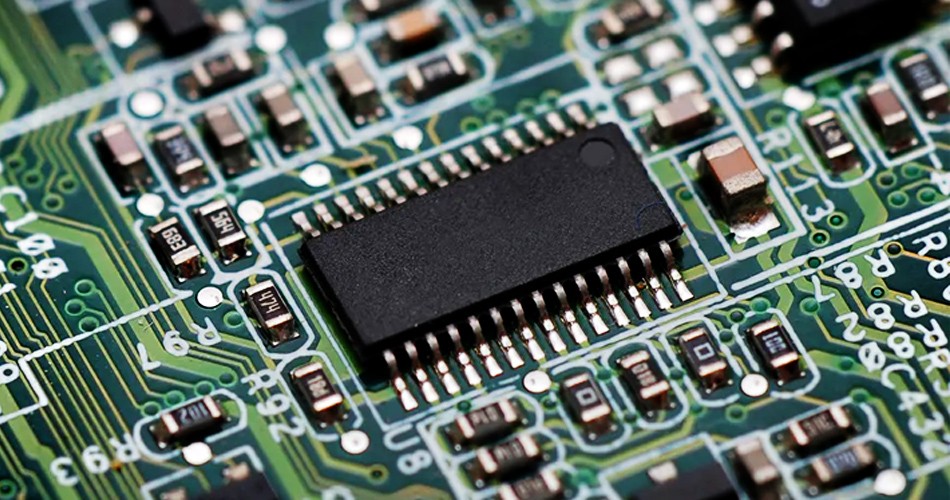

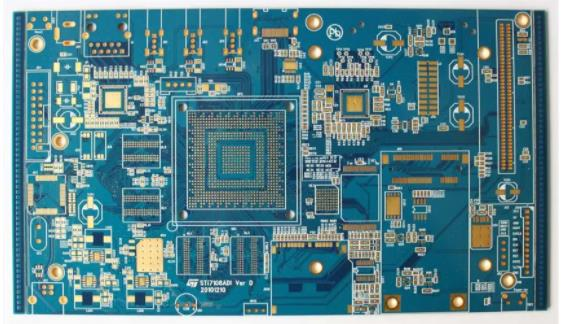

Printed circuit boards(PCBs) are the foundation for supporting and connecting surface mount and socket components in a variety of electronIC products. In fact, most electronic products use PCBs due to their many advantages. There are also some disadvantages to using a printed circuit board. If you're not sure if a PCB is right for your electronics, let's explore the pros and cons to help you better understand what you need.

Advantages of printed circuit boards

Complex routing is not a problem: PCBs are designed to require little complex routing on the board. By automating production equipment, the surface of the circuit board can be etched with the correct electronic circuit.

Better Quality Control: Once the board is designed and developed, testing is a breeze. You can perform quality control testing throughout the production cycle to ensure your boards are ready to use after the manufacturing process is complete.

Ease of Maintenance: Since the components of the PCB are held in place, only limited maintenance is required. There are no loose parts or complicated wiring (as mentioned above), so it is easy to identify different parts and perform maintenance.

Low probability of short circuits: relying on embedded copper traces, the PCB is virtually immune to short circuits. Also, the problem of wiring errors is minimized, and open circuits rarely occur. Plus, you'll be doing quality control testing, so if anything does go wrong, you can stop it in their tracks.

Disadvantages of printed circuit boards

Single Use Boards: printed circuit boards are designed with single use in mind. If you want to modify the board after printing, you won't be able to, and you will need to create a new board from scratch. However, if you need to create a new board to replace the one that needs to be modified, the lower manufacturing cost may work to your advantage.

Etching is not an eco-friendly process: the chEMIcals used in etching have a negative impact on the environment. While the etching process is great for plates, it's not particularly great for planets.

Compatibility: When designing PCBs, you must keep in mind that they are not compatible with every electronic device. Before you start making a circuit board, you need to decide what device you want to design for.

What are the characteristics of special solder resist for printed circuit boards

resistance solder flux is a printed circuit board assembly that is coated before the printing plate, its main function is to prevent "wires" and short circuits during the wave soldering process, and to protect the printed circuit board permanently. In addition, the printer can save solder, reduce the weight of the PCB board, and reduce the cost.

The solder resist has the following properties: high temperature resistance, brazing temperature (260±2℃), no softening and no damage within the specified welding time (5±2); good electrical properties, the surface insulation resistance should be greater than 1×10^ ( 3). Alcohol, acetone, banana water and other solvents. There is a certain wear resistance, in the printing plate and other machine processing. The solder film should not be damaged. The color is beautiful and even

According to curing conditions, it can be divided into two types: hot solid type and light solid type, hot solid type resistance flux, one-component and two-component. One-component modified epoxy resin, alkyd resin, amino resin, acrylic resin, polyurethane resin, melamine resin, silicone, epoxy resin are the main raw materials, and appropriate amount of pigment, filler, curing agent, solvent, and auxiliary materials are added. Grinded.

Two-component thermal curing flux is a curing agent of imidazole or amine, i.e. solid or liquid epoxy resin that cures. UV curing flux is a commonly used solder resist in printing factories. Its main components are: light solid resin, photosensitizer, diluent, pigment, leveling agent and thixotropic agent.

Photosolid resin is mainly composed of epoxy resin acrylate and its modifier, diluent and photosensitizer, mainly polyacrylate, generally phenyl ether. This solder resist is characterized by ultraviolet irradiation within a certain wavelength range, and the cross-linking reaction can rapidly cure the film. Usually does not contain volatile solvents, low temperature fast curing, can meet the requirements of mass production automation, high production efficiency, good product quality, heat-resistant curing flux accounts for more than ten of the energy.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱