Defects of pure tin electroplating on PCB

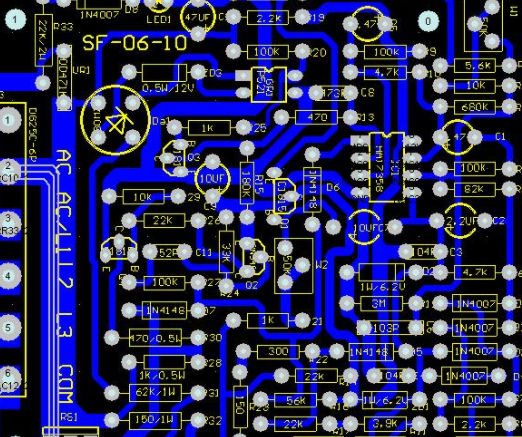

1 Introduction: Due to cost factors, most manufacturers still use wet film technology for imaging of printed circuit boards in the production process, whICh will inevitably lead to problems such as "bleeding", bright edge (thin tin) "And other unspecified problems when electroplating pure tin in graphics Copper plating pattern Transfer acid degreasing Second countercurrent rinsing Microetching Second countercurrent rinsing Acid immersion Tin plating Second countercurrent rinsing Acid immersion Pattern copper plating Second countercurrent rinsing Acid immersion Nickel plating Second countercurrent rinsing Citric acid immersion Gold plating Recycling Grade 2-3 pure water washing Dry

Printed circuit board

2. Analysis of the reasons for "seepage plate" of wet film board (quality problem of non pure tin syrup)

2.1 The copper surface brushed before screen printing must be clean to ensure good adhesion between the copper surface and the wet oil film

2.2 When the exposure energy of the wet film is low, the photo curing of the wet film will be incomplete, and the electroplating resistance of pure tin is poor

2.3 The wet film pre baking parameters are unreasonable, and the local temperature difference of the oven is large Because the thermal curing process of photosensitive data is sensitive to temperature, low temperature will lead to incomplete thermal curing, thus reducing the resistance of wet film to pure tin plating

2.4 Lack of post curing/curing treatment reduces the resistance of pure tin plating

2.5 Electroplated pure tin plate must be thoroughly cleaned At the same time, each plate must be inserted into the rack or dry plate, and it is not allowed to stack plates

2.6 Wet film quality problems

2.7 Impact of production and storage environment and time Bad storage environment or long time storage will lead to wet film expansion, reducing its resistance to pure tin plating

2.8 The pure tin polish and other organic pollutants in the tin cylinder erode and dissolve the wet film When the anode area of the tin plating bath is insufficient, the current efficiency will inevitably decrease, and oxygen evolution during the electroplating process (electroplating principle: anode oxygen evolution, catalog hydrogen evolution) If the current density is too high and the sulfuric acid content is too high, the cathode will release hydrogen, which will attack the wet film and lead to the occurrence of tin penetration (that is, the so calLED "penetration plating")

2.9 The high concentration of the stripping solution (sodium hydroxide solution), high temperature or long soaping time will produce tin flow or dissolved tin (that is, the so called "depth plating")

2.10 The current density of pure tin plating is too high Generally, the mass current density of wet film is applicable to 1.0 and 2.0A/dm2. If the current density range is exceeded, some wet film masses are prone to "infiltration"

3. Causes and improvement measures of "depth plating" caused by the problem of point

3.1 Cause: The "penetration" caused by the problem of liquid medicine mainly depends on the formula of pure tin brightener The polish has a strong penetration ability, and the erosion of the wet film during the electroplating process will produce "penetration" That is, when too much pure tin brightener is added or the current is slightly higher, a "water permeable coating" appears Under normal current operation, the resulting "penetration coating" is related to the uncontrolled operating conditions of the agent, such as excessive pure tin brightener, High current, high stannous sulfate or sulfuric acid content, etc, These will accelerate the erosion of the wet film

3.2 Improvement countermeasure: the efficiency of most pure tin brighteners determines that they are more aggressive to wet film under the action of current In order to avoid "bleeding" of wet film pure tin plating, it is recommended to produce wet film pure tin plating at ordinary tiMES The board must do three things:

1) When adding pure tin light agent, the content of pure tin light agent in the plating solution is normally controlled at the lower limit;

2) The current density is controlled within the allowable range;

3) The control of the composition of the coating, such as controlling the stannous sulfate and sulfuric acid content at the lower limit, is also conducive to improving the "water permeable coating"

The characteristics of MARKet pure tin light agent

4.1 Some pure tin brighteners are limited to current density and have relatively narrow working range This pure tin brightener is usually prone to wet film "bleeding" It controls the operating parameters of stannous sulfate, sulfuric acid and current density relative The allowable standard range is also narrow;

4.2 Some pure tin brighteners are suitable for a wide range of current density operations This pure tin brightener is usually not easy to produce wet film "tin infiltration" This is the allowable standard for the control of operating parameters relative to stannous sulfate, sulfuric acid and current density wide range;

4.3 Some pure tin brighteners are easy to "leak plating, blackening" or even "shining" at the edge of the wet film;

4.4 Some pure tin lighteners do not cause the problem of "brightness" of the edge of the wet film (no baking or UV curing) improve. Before the pure tin plating process on the wet film board, without baking or UV curing treatment, there is no "bright and penetration plating" problem at the line edge At present, there are really few pure tin brighteners on the market The specific operation shall be based on the characteristics of pure tin brightener provided by different syrup suppliers, working current density and other parameters, temperature, anode area, stannous sulfate, and the content of sulfuric acid and tin brightener shall be strictly controlled

The above is the explanation given by the editor of PCB circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱