What is the packaging of PCB components?

Packaging is usually a PCB assembly process Because this is a chEMIcal process, electronIC design engineers are not good at packaging the interaction between systems and components Experience usually coMES from trial and error Extensive discussion at the beginning of the design process can save a lot of time and cost

paraphrase

Encapsulation is the impregnation of electronIC components or electronIC components. Potting involves an enclosure that is used throughout the application. Use a mold to encapsulate, then fill the component, and release the component from the mold to form a shell.

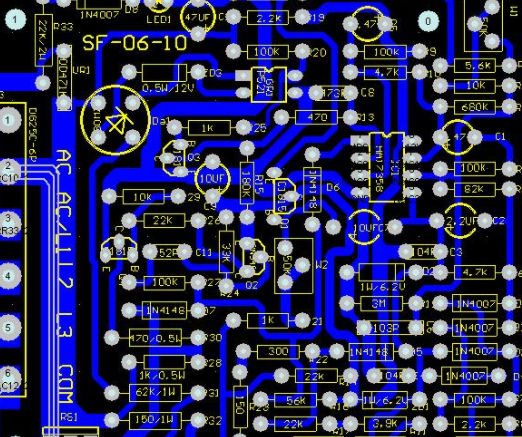

This paper will give the purpose of potting, which is the most common process SMT

The use of encapsulation systems has many advantages, such as water resistance, dust prevention, direct contact with harsh environments, conductive contaminants, chemical attack, and resistance to vibration and shock. Encapsulation provides structural reinforcement and improves power insulation and heat dissipation efficiency. This allows for tighter assembly of high-pressure components.

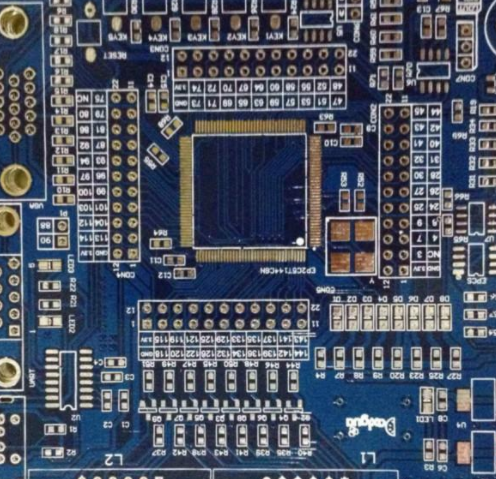

Circuit board

Unfortunately, packaging and encapsulation are often considered to be the last stage of the production process, unrelated to general electrical design, and involving chemical engineering. If the electronic designer has a comprehensive view from the beginning and is familiar with the potting adhesive supplier, a lot of time and money can be saved.

The most common encapsulation compounds are based on two-component systems. Within a specified time, the two liquids are mixed together to form a solid compound. This is usually a misunderstanding. The reaction time can be adjusted by adjusting the ratio between the two liquids to form a solid. In order to achieve the final curing efficiency of materials, it is necessary to accurately maintain the ratio of the two. In the process of mixing, it is also important that the two liquids be carefully and thoroughly mixed evenly. Any unmixed liquid will not solidify and may cause problems during the life cycle of the component. PCB assembly package

Selection of potting materials

First, the storage, operation and peak temperature of components must be considered. This will soon give you the types of materials you can use. The thermal efficiency of the data is usually selected based on long-term exposure;

*Polyurethane - 50 ℃ 140 ℃;

*Epoxy resin is - 40 ℃ and 150 ℃. With a certain system, it can reach 200 ℃;

*Silicone adhesive - 60 ° C 250 ° C.

These digits are different for different products and exposure times. For example, some polyurethanes can withstand short-term peak temperatures during reflow soldering. However, these data can serve as a good starting point.

Hardening, expansion and contraction during thermal cycling are also key factors for packaging compounds in electronic applications.

Polyurethane can be customized to any HS hardness from 3000 (such as soft gel) to 90 D (hard glass). It can provide high elongation and good tear resistance. Depending on the hardness, the expansion and contraction properties will vary with the temperature range.

The epoxy resin has an inherently rigid system up to 90 D. Because of their rigidity, they have low expansion and contraction characteristics, but they are usually not used for PCB components because the rigidity cannot match the solder. As is known to all, PCB solder joints will crack and bring stress to components during thermal cycling. In addition, when they are exposed to low temperature, they become fragile due to rigidity. Therefore, during transportation and storage, they are very sensitive to impact and vibration in cold areas. PCB assembly package

Silicone adhesive is a soft system, 2000 to 90 A. They have high expansion and contraction characteristics, but because they are soft, they will not bring interaction and pressure to components, substrate and PCB solder joints Silicon resin is usually used in electronic designs that are prone to failure When troubleshooting, it is necessary to rework the substrate and remove the encapsulation compound This is obviously a conflict, because components are inevitably encapsulated to ensure that there is no leak path The ability to remove the potting compound indicates poor adhesion, which violates the principle of using potting adhesive For example, a large number of LED driver manufacturers use silica gel to repair poor electronic designs, but due to lack of adhesion, it often fails due to water seepage

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱