What are the inspection conditions and standards for PCBA circuit boards

With the improvement of product qualifICation rate, the pass through rate of products will be greatly improved. PCBA testing is a link in the whole production process of PCBA processing and an important means to control product quality.

In order to ensure the high quality and reliability of the assembled PCB, PCB manufacturers and assemblers must inspect the PCB at different stages of the manufacturing and assembly process to eliminate surface defects. In addition, timely and professional inspection can lead to defects exposed before electrical testing, and is conducive to the accumulation of statistical process control (SPC) data.

1、 To improve the qualification rate of products

With the improvement of product qualification rate, the pass through rate of products will be greatly improved. PCBA testing is a link in the whole production process of PCBA processing and an important means to control product quality.

2、 For better user experience

If conditions permit, every product needs basic tests, such as ICT test, FCT test, some tests, such as fatigue test, pressure test under harsh environment, aging test, and sampling products that can only be tested. Our heart will have a bottom, and only products that can stand the test will be liked by users. If problems are found in the testing process, we can also correct and adjust them in time to make the whole product more complete and avoid serious consequences after the product is put on the MARKet.

What are the inspection conditions and standards for PCBA circuit boards

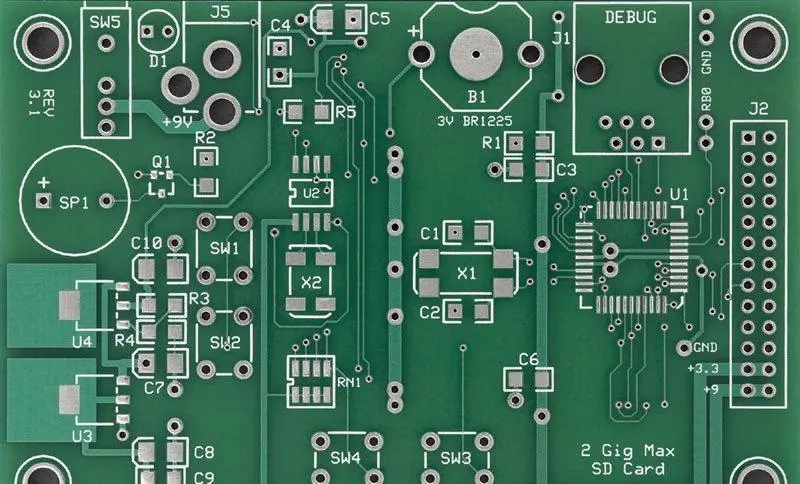

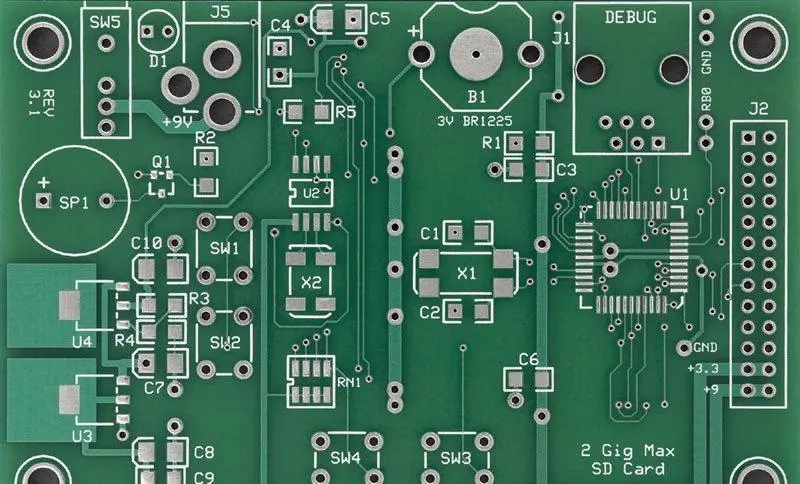

3、 Inspection conditions of PCBA circuit board

1. In order to prevent parts from being polluted, you must choose EOS/ESD full protective gloves or finger cots and wear electrostatic rings. The light source is white or fluorescent. The light intensity must be more than 100 lux and can be clearly analyzed and visible within 10 seconds.

2. Inspection method: place the product about 40cm away from the eyes, about 45 degrees up and down, and use visual inspection or triple magnifier for inspection.

3. Inspection standard: (according to the level of QS9000? Sampling=0 AQL=0.4%; as a special customer's requirement, it is determined by the customer's acceptance standard)

4. Sampling plan: MIL-STD-105E Class II standard single sampling

5. Criteria for inspection: serious defect (CR) AQL 0%

6. Main Disadvantages (MA) AQL 0.4%

7. One minor defect (MI) AQL 0.65%

4、 PCBA board inspection standard

1. Serious defect (represented by CR): any defect that is sufficient to cause injury to people or machines or endanger life safety, such as non-compliance with safety regulations/machine burning/electric shock.

2. Main defects (represented by MA): defects that may cause damage to the product, abnormal function or affect the service life of the product due to material reasons.

3. Minor defects (expressed in MI): they do not affect the function and service life of the product, the appearance has defects, and the mechanism assembly has minor defects or differences.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱