How to Improve Production EffICiency in PCB Factory

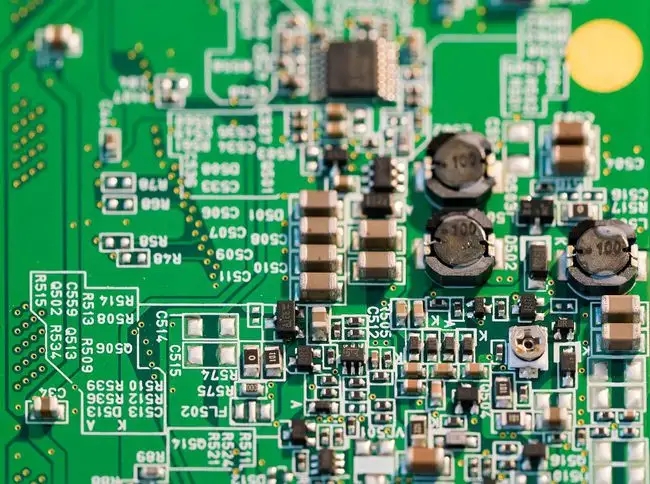

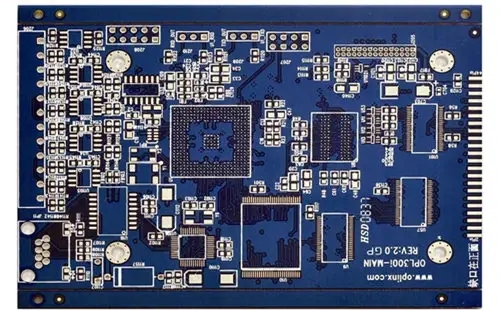

How to improve production efficiency and ensure product quality in PCBA processing plants? It is necessary to establish equipment maintenance rules and regulations. Ensuring that the equipment is always in good condition for normal operation is an important means to ensure product quality and production efficiency.

How to improve production efficiency and ensure product quality in PCBA processing plants? It is necessary to establish equipment maintenance rules and regulations. Ensuring that the equipment is always in good condition for normal operation is an important means to ensure product quality and production efficiency.

(1) Strengthen the daily maintenance of the machine

SMT mounting machine is a very complicated high-tech and high-precision machine, which requires to work in a constant temperature, humidity and very clean environment. The daily, weekly, monthly, sEMI annual and annual maintenance instructions must be adhered to in strict accordance with the requirements of the equipment regulations, and the daily maintenance work must be done well.

How to improve production efficiency and ensure quality in PCBA processing plant

(2) Requirements for equipment operators

(3) Develop measures to reduce or avoid errors

When SMT mounting, the most easy and frequent errors are wrong components and incorrect mounting position. Therefore, the following measures are formulated to prevent them.

① After the feeder is programmed, a specially assigned person must check whether the element values on each numbered position of the material station are consistent with the element values of the corresponding feeder number in the programming table. If it is inconsistent, it must be correct.

② The belt feeder is used to replenish the material after each tray is pasted. A specially assigned person must check whether the newly instalLED pallet value is correct.

③ It must be edited once after chip programming. Check whether the element number, rotation angle and mounting position of each mounting step are correct.

④ Each batch of products must be inspected by a specially assigned person after the first piece is pasted. If problems are found, they should be corrected in time by modifying procedures.

⑤ In the process of mounting, always check whether the mounting position is right or not, and throw materials. The technicians on the SMT processing line shall timely check and eliminate any problems found.

⑥ Set the pre welding inspection station (manually or through AOI)

In a word, the SMT mounting speed and mounting accuracy are certain. Human factors are very important for how to play the role of PCBA processing equipment. Effective rules and regulations and management measures should be formulated to ensure the normal operation of the machine and ensure the quality and efficiency of mounting.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱