How to evaluate a SMT foundry for PCB process

We usually call "electronIC foundry" EMS or CM. When it coMES to how to evaluate an electronic foundry, whether an SMT or a OEM of a complete machine, I remember that there seems to be a six word formula of TQRDCE, which can help the evaluator to consider multiple aspects.

T: Technology depends on the technology of this factory and whether it meets the requirements.

Q: Quality is about quality.

R: Responsiveness depends on whether the manufacturer asks the customer whether the promise is real-time and correct.

D: Delivery is the delivery date of the product.

C: Is the cost reasonable.

E: Whether Environmental contributes to the environment.

Generally speaking, the evaluation of a foundry can not be completed by a single person, but should at least involve procurement personnel or business personnel, engineering personnel, and quality control personnel. Because each person has different functions, the face and focus of the evaluation will be different. Basically, purchasing personnel and business personnel focus on the price and delivery date of products; The engineers focus on technology, process capability and equipment; Quality control personnel focus on product quality control; The rest of Responsiveness and Environmental should be paid attention to.

The items to be checked when evaluating a SMT OEM are listed below for reference only. Generally speaking, these items are the basis for scoring, and most companies will have different weights according to the needs of individual companies.

Technology: Is there any advanced manufacturing process, automation and other equipment? Is there any process innovation capability? Is there the ability to introduce new processes into the MARKet?

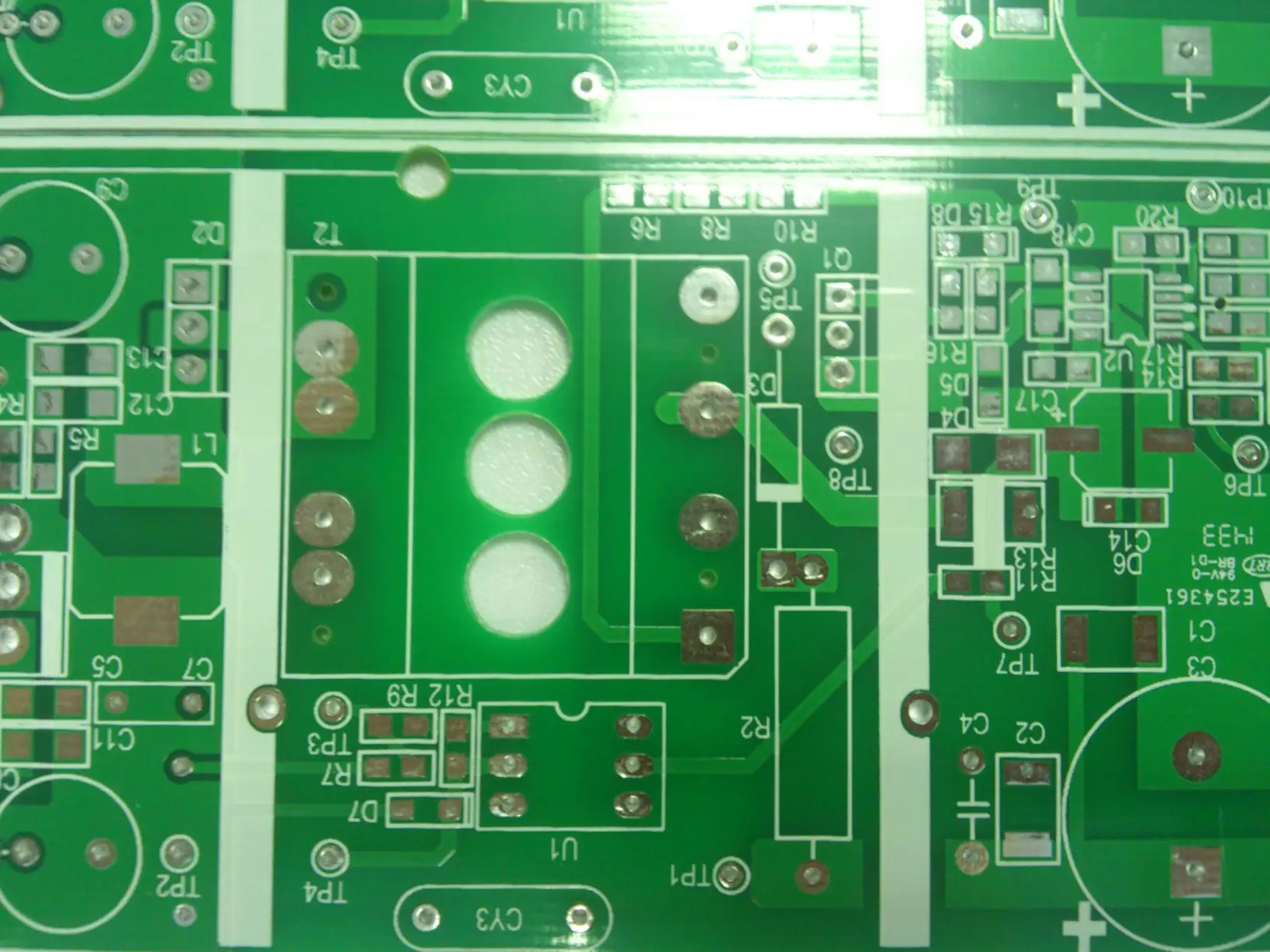

Process capability evaluation: repair capability of BGA IC; 0201 Welding and repair capability of parts; RoHS implementation; SOP integrity; How to operate special-shaped parts; How to operate the Tube material packaging; How the tray packaging works; How to avoid wrong materials and reverse polarity; Is there any guidance on circuit board design for customers; Is there the ability to review circuit board design and provide DFM (design For; Manufacturing); MSL (Moisture Sensitivity Level) parts control capability; Solder paste rewarming, unsealing, storage life control capability; De panel process

Equipment: Solder paste printing machine precision; SMT pick&place machine accuracy; Whether there is AOI (Automated Optical Inspection); ICT test equipment (Agilent 3070, GenRad, TR5000)

Quality: Is there any factory certification? Such as ISO, TS., etc. Is SPC imported, such as Cpk control of part size and production control chart? Is there any continuous quality control improvement activity? QCC or TQM; ECO (Engineering Change Order) Engineeing Change management; Are there any parts under Waive control? If any quality problem is found, can you notify the customer in real time and keep in touch with the customer? Quality control evaluation; Incoming inspection records and management; SMT yield; Customer complaint reply; Document management; BOM maintenance; ESD anti-static implementation; Whether the inspection instrument is calibrated

Control of qualified parts and suppliers (AML&AVL management)

AML: Approved Materials List

AVL: Approved Vendor List

Response: Can you quickly respond to the customer's questions within 24 hours? Can new orders from customers be responded to in real time? Can customers rapidly expand their capacity when they have urgent orders? How quickly can you react when the customer's project changes? How fast and how to deal with customer complaints?

Delivery: on time delivery; The delivery date meets the company's needs; Expedite the delivery of goods and answer the destination

Cost: Continuously improve the price reduction; Is the quotation detaiLED?

Environmental: Do you recognize the impact of pcb factories on the environment and take countermeasures? Do you try your best to conform to environmental protection from the beginning of product design? Whether to improve the impact on the environment from daily work?

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱