Teach you how to quICkly configure the smt production line

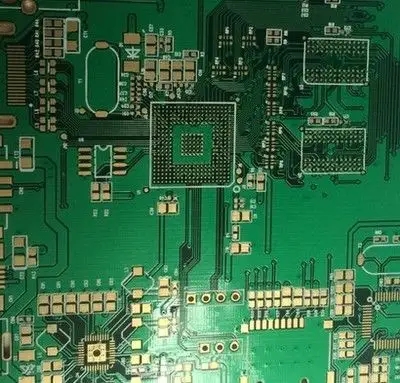

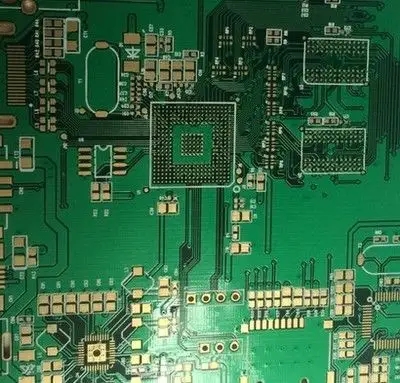

Generally, the smt production process includes three steps: solder paste printing, mounting and reflow soldering. To build a complete SMT production line, it must include the equipment that implements the above process steps: printing machine, mounting machine and reflow soldering furnace. The mounting machine accounts for more than 70% of the investment in the whole production line, so the selection of mounting machine is the most critical. 1. According to the scale and speed, the mounters can be divided into large high-speed mounters, medium speed mounters and SMAll mounters. The previous large mounters also have the difference between high-speed mounters and high-precision mounters, which requires the cooperation of two mounters to play a relatively high efficiency; Now there are many

Generally, the smt production process includes three steps: solder paste printing, mounting and reflow soldering. To build a complete SMT production line, it must include the equipment that implements the above process steps: printing machine, mounting machine and reflow soldering furnace. The mounting machine accounts for more than 70% of the investment in the whole production line, so the selection of mounting machine is the most critical.

1. chip mounter

According to the scale and speed, it can be divided into large high-speed mounters, medium speed mounters and small mounters. The previous large mounters were also divided into high-speed mounters and high-precision mounters, which required the cooperation of two mounters to play a relatively high efficiency; Nowadays, there are many multi-functional mounters, which enable a multi-functional mounter to complete the mounting of all components while maintaining a high mounting speed, which can reduce investment and is more suitable for small and medium-sized enterprises and scientific research institutions. Typical ones are Siemens F5 series, Panasonic MSF, etc.

At present, the mounter structure can be roughly divided into four types: boom type (also known as "arch type"), composite type, turret type and large parallel system.

The boom type machine is the most traditional chip mounter, which has good flexibility and accuracy and is suitable for most components. High precision machines are generally of this type, but its speed cannot be compared with that of composite, turret and large parallel systems.

The compound machine is developed from the boom type machine. It combines the characteristics of the turret type and the boom type. It can increase the speed by increasing the number of booms, and has greater flexibility.

The turret type machine is mainly used in the production of large-scale computer boards, mobile phones, household appliances and other products. This is because among these products, there are many resistance and capacitance components, and the assembly density is high. It is very suitable for this type of machine to be used for production.

Large scale parallel systems use a series of small, separate mounting units. Each unit has its own screw position system, equipped with CAMera and mounting head. Each mounting head can absorb a limited belt feeder, mount a part of PCB, and PCB moves in the machine step by step at a fixed interval. The individual units run slowly. However, their continuous or parallel operation will have high output.

The test shows that the installation accuracy of the boom type machine is good, and the installation speed is 5000 to 20000 elements per hour (cph). The assembly speed of compound and turret machines is relatively high, generally 20000 to 50000 per hour. The assembly speed of large parallel systems is the fastest, reaching 50000 to 100000.

2. Printing press

The printing machine can be divided into sEMI-automatic and full-automatic. The semi-automatic can not be connected with other SMT equipment, which requires human intervention (such as the conveyor board). However, it is SIMple in structure and cheap (only 1/10 to 1/5 of the full-automatic model), which is suitable for scientific research institutes. The typical model is DEK 248. The full-automatic printing machine can be connected to the SMT production line without human intervention. It is highly automatic and suitable for large-scale production.

3. Reflow soldering furnace

Reflow soldering equipment plays a decisive role in the welding quality of surface mounted components (SMC/SMD) and is the key equipment of smt production line. At present, the reflow soldering equipment is developing towards high efficiency, multi-function and intelligence.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱