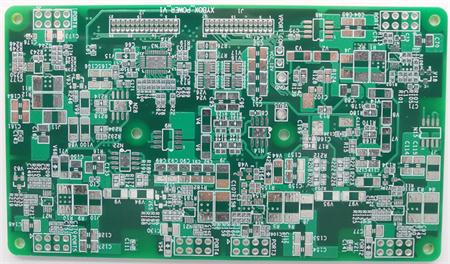

It's beyond my imagination. Complete set of PCBA board detection methods

Due to the continuous maturity of the current SMT technology, the components in the PCBA assembly process become SMAller and smaller, making PCBA more powerful. At the same time, it also brings great challenges to testing and inspection. Testing is a crucial step to ensure the delivery of high-quality PCBA products to customers. Inspection and testing can reduce processing risks. The following is a collection of several test methods in the PCBA processing industry.

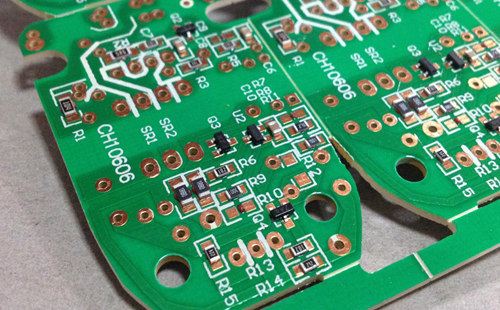

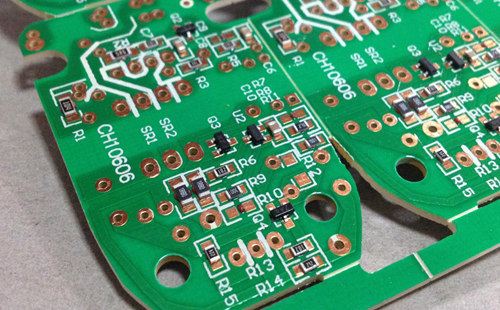

1. Manual visual inspection

Visual inspection can be carried out in each step of the PCBA process. Manual visual inspection of PCBA assembly is the most original method in PCBA quality inspection. Only eyes and magnifying glass are used to check the welding condition of the circuit and electronIC components of PCBA board, such as the welding method, whether the solder joints are bridged, whether there is less welding and whether there is welding incompleteness. The magnifying glass is the basIC tool in visual inspection, and the metal needle can be used to check the incomplete welding on the IC lead.

2. On line tester (ICT)

Online tester is widely used in PCBA processing industry because of its excellent testing and inspection performance. ICT can almost find welding and assembly problems in PCBA. It has high speed and high stability. The electric probe tests and fills the Printed Circuit Board (PCB) to check short circuit, open circuit, resistance, capacitance and other basic quantities to show whether the components are manufactured correctly.

3. Automatic Optical Inspection (AOI)

Automatic optical inspection is a non-contact testing method. Automatic optical inspection plays an important role in inspection. Automatic optical inspection is an automatic visual inspection during the manufacturing process of printed circuit boards, in which the CAMera automatically scans the PCBA boards under test for catastrophic failures (such as missing parts) and quality defects (such as fillet size or shape or component deflection).

4. Automatic Optical Inspection (AXI)

For the widespread use of BGA and CSP, typical inspection methods such as ICT cannot check the embedded solder joints of components. AXI can test for misalignment, lack of ball and solder deposition. AXI uses X-rays to penetrate solid objects to capture their photos. It can be divided into two types: 2D and 3D.

5. Functional circuit test

The functional circuit test is the last test before PCBA products are launched. Different from other tests (such as AOI, AXI and ICT), FCT aims to make UUT (unit under test) work in a SIMulated environment and use output data to check its actual performance.

6. Sample inspection

Before mass production and assembly, PCB manufacturers and assemblers usually carry out first sample inspection to check whether SMT equipment has been properly prepared, so as to avoid problems of vacuum nozzle or arrangement in mass production, which may lead to problems in PCBA board production. This is calLED first piece inspection.

7. Flying needle tester

The flying probe is applicable to the inspection of highly complex PCBs that require expensive inspection costs. The design and inspection of the flying needle can be completed in one day, and the assembly cost is relatively low. It can check the open circuit, short circuit and direction of components installed on PCB. In addition, it works well in identifying component layout and alignment.

8. Manufacturing Defect Analyzer (MDA)

The purpose of MDA is only to conduct visual tests on the board to reveal manufacturing defects. Since most manufacturing defects are simple connection problems, MDA is limited to measuring continuity. Typically, the tester will be able to detect the presence of resistors, capacitors, and transistors. The protection diode can also be used to detect the integrated circuit to indicate whether the components are placed correctly.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱