According to the color of the PCB, identify the quality. In fact, the color of the motherboard has nothing to do with the performance of the PCB.

The higher the appearance of a PCB, the better it will be used.

The color of PCB surface is actually the color of solder resist. Solder resist can avoid the occurrence of wrong soldering of components, and slow down the servICe life of components, so as to avoid air oxidation and erosion of components.

If you have a better understanding of the PCB parts of large and medium-sized enterprises such as Huawei mobile phones and ZTE, you can see that the color is generally green. This is because the green processing technology is the most perfect and SIMple.

In addition to green, the color of PCB can be said to be "fancy": white, light yellow, red, dark blue, sub light color, and even chrysanthemum, blue purple, black, bright green, etc. There are white because it is a dye that must be used to make lighting products, while the application of other colors is free so as to MARK the goods. From product research and development to commodity floor style, depending on the different main uses of PCB boards, the enterprise may use blue and purple for test boards, red for the most important boards, and black for internal parts of electronic computers.

The most common PCB board is green board, also known as green oil. its solder resist ink is the oldest, most cost-effective and most popular. Green oil has many advantages besides perfect processing technology:

In the production and processing of pcb, the production and manufacturing of electronic equipment includes the plate making process and its pasting. During this period, several processes will go through the white light room, and the visual impact of green PCB in the white light room is the best; Secondly, during SMT chip production and processing, the process of tin coating, chip mounting and AOI calibration must be accurately positioned and calibrated by electronic optics. The identification of green negative plate instruments and equipment is more friendly.

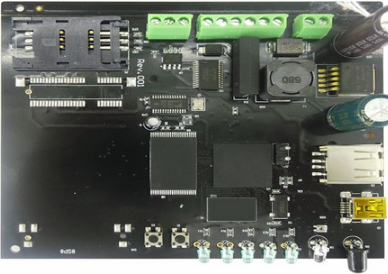

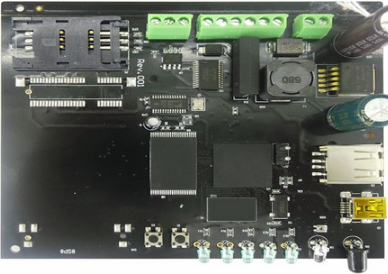

PCB board

Part of the inspection process depends on the observation of employees (but now most of them use flying needle detection instead of manual service). They keep staring at the wood under strong light, and green is friendly to both eyes. The green PCB is also more environmentally friendly. It is not easy to release harmful gases when it is purchased at high temperature.

Other PCB colors, such as dark blue and black, are respectively doped with cobalt and carbon. Due to their weak conductivity, they also have the risk of short circuit failure.

If it is too deep, it usually increases the difficulty factor of mainboard detection and maintenance. Based on the analysis of the characteristics of the black board, it is very easy for the black board to cause color deviation due to the difficulties of processing technology and raw materials in production and manufacturing, resulting in a high PCB rejection rate. The wiring of black PCB is difficult to identify, which will increase the difficulty factor for mid and late maintenance and debugging. Many pcb processing plants do not use black PCB. Even in the military and industrial automation industries, green PCB based steel plates are used for products with very high quality requirements.

Next, let's talk about what harm does the color of solder resist ink do to the board?

As for the finished products, the harm of different inks to the boards is mainly reflected in their appearance, which is also a problem of how to look at them. For example, green includes sunlight green, light green, dark green, matte green, etc. The color is light, so it is very easy to see that the boards after the cork hole processing process are not good-looking. Some manufacturers also have poor inks, epoxy resin and dyeing agent are not well prepared, which will lead to problems such as bubbles, Light color changes can also be detected; For the hazards of sEMI-finished product processing, the key is reflected in the level of manufacturing difficulty coefficient. This problem is a bit complicated to express. Different colors of ink have different dyeing processes, electrostatic powder spraying, paint spraying, ink printing, ink preparation is also different, and even a little wrong color is a problem.

Although the ink color does no harm to PCB, the ink thickness does great harm to the characteristic impedance, especially for the water-based parts, which are extremely strict in the manipulation of the ink thickness; The red ink is thin and thick, and the bubbles are easy to manipulate. The red ink covers the route, which can cover some defects. The appearance is more beautiful, but the price is expensive. During imaging, the exposure of red and light yellow is more stable, while white is the least easy to manipulate.

In general, color does not do any harm to the characteristics of finished boards, and it does little harm to PCB assembly and other stages; In PCB design, it is important to strictly control every key point in every stage to turn a PCB into a good one. PCB motherboards with different colors are mainly used to serve the full range of colors, flavors and commodities. It is not recommended that we take color as a key factor in PCB production and processing.

Therefore, the color of PCB has nothing to do with the usability of finished PCB products.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱