Inspection precautions when the customer receives the circuit board from the SMT manufacturer

SMT chip processing is to mount electronIC components on PCB bare board and realize welding through successive processes.

First, print the solder paste of the welding material on the bonding pad of the bare PCB

Then, use the placement machine to mount the electronIC components onto the bonding pads of the PCB bare board (these pads have solder paste, which has a certain viscosity, and can stick to the electronic components)

Next, send PCB board to reflow soldering for soldering

Finally, use AOI detector to check the welded PCB to ensure that there are no welding defects. This process is calLED SMT chip processing

When the customer receives the circuit board from the smt manufacturer, he should check all the circuit boards, including the production copy of smt. The customer received the circuit board, but not all specifications need to be checked, but through years of experience and experience, this check is still necessary!

Now let's talk about some points that should be checked when receiving the circuit board from the SMT chip processing factory.

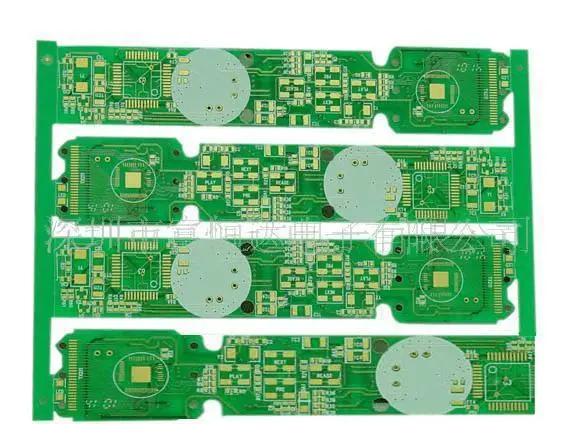

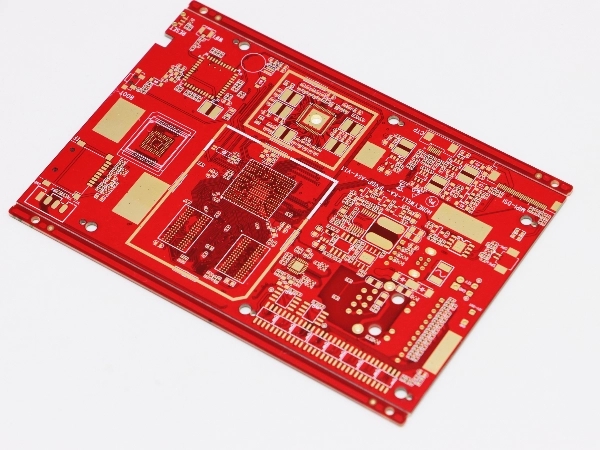

1. Check the original appearance of the circuit board. Pay attention to cleanliness and appearance inspection.

2. Check the mask, including (specified color, specified thickness, quality defects, pitting) 3. Is the electroplating sufficient? Sufficient plating is difficult to measure. If the requirements are strict, the current requirements are based on the plating thickness.

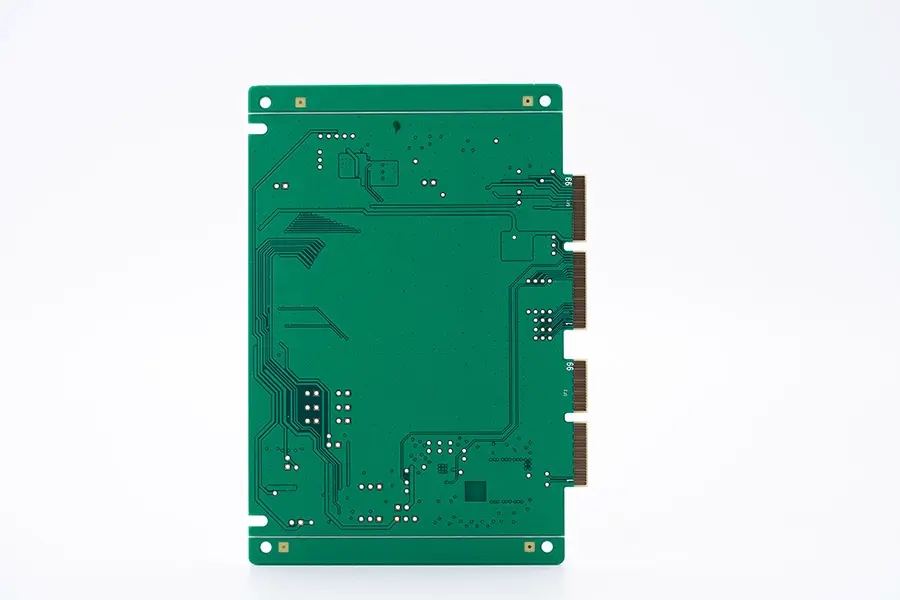

4. Is the hole centered on the pad? (RING AND ALIGNMENT)

5. Is the hole size correct?

6. Does the appearance conform to the artwork?

7. Does the stencil match the printed position of the circuit board?

8. Is the overall circuit board size correct?

9. Is the PCB warped?

10. Is there copper beside PCB?

11. PCB tracking width tolerance.

The above is a series of inspections that customers should carry out when receiving products. Better inspections can avoid long-term troubleshooting in the future, saving time and cost.

PCB manufacturers, PCB designers and PCBA manufacturers explain the inspection precautions when customers receive PCB from SMT manufacturers.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱