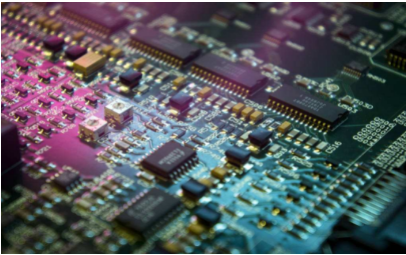

PCB multilayer circuit boards are usually defined as 10-20 or more advanced ones, whICh are more difficult to process than traditional multilayer circuit boards, and require high quality and reliability. It is mainly used in communication equipment, high-end servers, medical electronics, aviation, industrial control, military and other fields. In recent years, the MARKet demand for multilayer circuit boards in communications, base stations, aviation, military and other fields is still strong.

With the rapid development of the communication equipment market in China, the multilayer circuit board market has broad prOSPects.

At present, the doMEStic enterprises that can mass produce high-level PCB mainly come from foreign-funded enterprises or a few domestic funded enterprises. The production of multilayer circuit boards requires not only higher investment in technology and equipment, but also the experience of technicians and producers.

At the same time, the customer authentication procedure of multilayer circuit board is also strict and cumbersome. Therefore, the threshold for multilayer circuit board to enter the enterprise is high, and the industrialization production cycle is long.

PCB average level has become an important technical indicator to measure the technical level and product structure of PCB enterprises. This paper briefly describes the main processing difficulties encountered in the production of high-level circuit boards, and introduces the control points of key production processes of multilayer circuit boards for reference.

Compared with traditional PCB products, multilayer circuit boards have the characteristics of more board thickness, more layers, dense lines, more through holes, large cell size, thin dielectric layer, etc., and have higher requirements for internal space, inter layer alignment, impedance control and reliability.

1. Difficulties in PCB inter layer alignment

Due to the large number of layers in multilayer circuit boards, users have higher and higher requirements for PCB layer calibration. Generally, the alignment tolerance between layers is controlLED at 75 microns. Considering the large unit size of the multilayer circuit board, the high temperature and humidity in the graphic conversion workshop, the dislocation overlap caused by the inconsistency of different core boards, and the positioning mode between layers, it is more difficult to control the alignment of the multilayer circuit board.

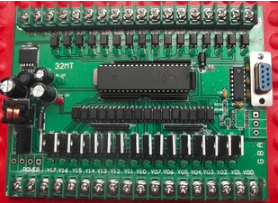

multi-storey

2. Difficulties in making internal circuits

Multilayer circuit boards are made of special materials such as high TG, high speed, high frequency, thick copper and thin dielectric layers, which put forward high requirements for internal circuit fabrication and graphic size control. For example, the integrity of impedance signal transmission increases the difficulty of internal circuit manufacturing.

The width and line spacing are SMAll, the open circuit and short circuit increase, the short circuit increases, and the qualification rate is low; There are many thin line signal layers, and the probability of AOI leakage detection in the inner layer increases; The inner core plate is thin, easy to wrinkle, poor exposure, and easy to curl when etching; High level plates are mostly system boards with large unit size and high product scrap cost.

3. Difficulties in compression manufacturing

Many inner core plates and sEMI solidified plates are overlapped, and defects such as sliding plate, delamination, resin void and bubble residue are easy to appear in stamping production. In PCB design of laminated structure, the heat resistance, voltage resistance, glue content and dielectric thickness of materials shall be fully considered, and a reasonable material pressing scheme for multilayer circuit boards shall be formulated.

Due to the large number of layers, the consistency between expansion and contraction control and size coefficient compensation cannot be maintained, and the interlaminar reliability test is easy to fail due to the thin layer insulation.

4. Difficulties in drilling

The use of high TG, high speed, high frequency, thick copper special plates increases the difficulty of drilling roughness, drilling burr and drilling dirt removal. The number of layers is large, the total copper thickness and plate thickness are accumulated, and the drilling tool is easy to break; CAF failure caused by many dense BGAs and narrow hole wall spacing; Inclined drilling is easy to occur due to the thickness of the plate.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱