Development status of three proofing paint process for electronIC engineering PCB?

The designers of electronic products and PCB manufacturers are faced with the pressure of making packaging SMAller, lighter and more environmentally friendly. They must also ensure that their new technology can operate reliably in their operating environment, which may include exposure to chEMIcals, moisture, static electricity, and extreme temperatures. Compared with products without three proofing paint, products with three proofing paint will perform better. Its function is mainly to improve the yield and reliability of products. Especially for products used in harsh environments, the three proofing paint can be divided into acrylate, silicon cutting and polyurethane three proofing paint in terms of chemical composition. In terms of curing methods, there are solvent curing, room temperature curing, thermal curing and UV curing. Typical uses include the following:

Three proof paint (common coating) for civil and commercial applications can protect electronic circuits in household appliances against water and detergents (washing machines, dishwashers, and outdoor electronic LED screens for sanitary products); External adverse environment (display screen, anti-theft, fire alarm device, etc.): chemical environment (air conditioner, dryer): harmful substances in offices and hoMES (computers, induction cookers); All other three protection circuit boards.

2. The automobile industry and the automobile industry require the three proofing paint to protect the circuit from the following hazards, such as gasoline evaporation, salt spray/brake fluid, etc. The application of electronic system in automobile is growing rapidly, the complexity of components is getting higher and higher, and it is developing towards multi-function components. The electronic sensors and systems in the compartment basically occupy the same space as the passengers in the vehicle. In winter, this may mean very cold. The moisture in the surrounding air may condense on the car. In summer, the air around the car may be hot and humid. The condensed water and high humidity will cause corrosion, which is a challenge to the reliability of electronic products. So use. Three proofing paint has become the basic requirement to ensure the long-term reliability of automotive Electronic devices.

3. AerOSPace, due to the particularity of the use environment, the aerospace environment has strict requirements on electronic equipment, especially under the conditions of rapid pressurization and decompression, it is still necessary to maintain good circuit performance. Therefore, the pressure stability of three proofing paint is widely used.

4. Navigation, whether fresh fresh water or salty sea water, will cause harm to the electrical circuit of the ship's equipment. The use of three proof paint can maximize the protection of equipment on the water surface and even submerged and underwater

5. Medical and three proof paint can protect electronic equipment from external chemical agents and special use environment to ensure its continuous stability.

With the improvement of people's living standards, the requirements for daily electronic products are getting higher and higher. More and more attention is paid to the quality and safety of products, and more and more electronic devices are applied to the safety of electronic devices in people's daily life. Three proofing paint is an important line of defense to protect electronic equipment. After spraying three proofing paint on electronic equipment, it can form a layer of elastic paint film to protect electronic products from high temperature and moisture The influence of external factors such as moisture and dust. The three proofing paint can also protect important lines of defense of electronic equipment. After spraying three proofing paint on electronic equipment, a layer of elastic paint film can be formed to protect electronic products from external factors such as high temperature, moisture and dust.

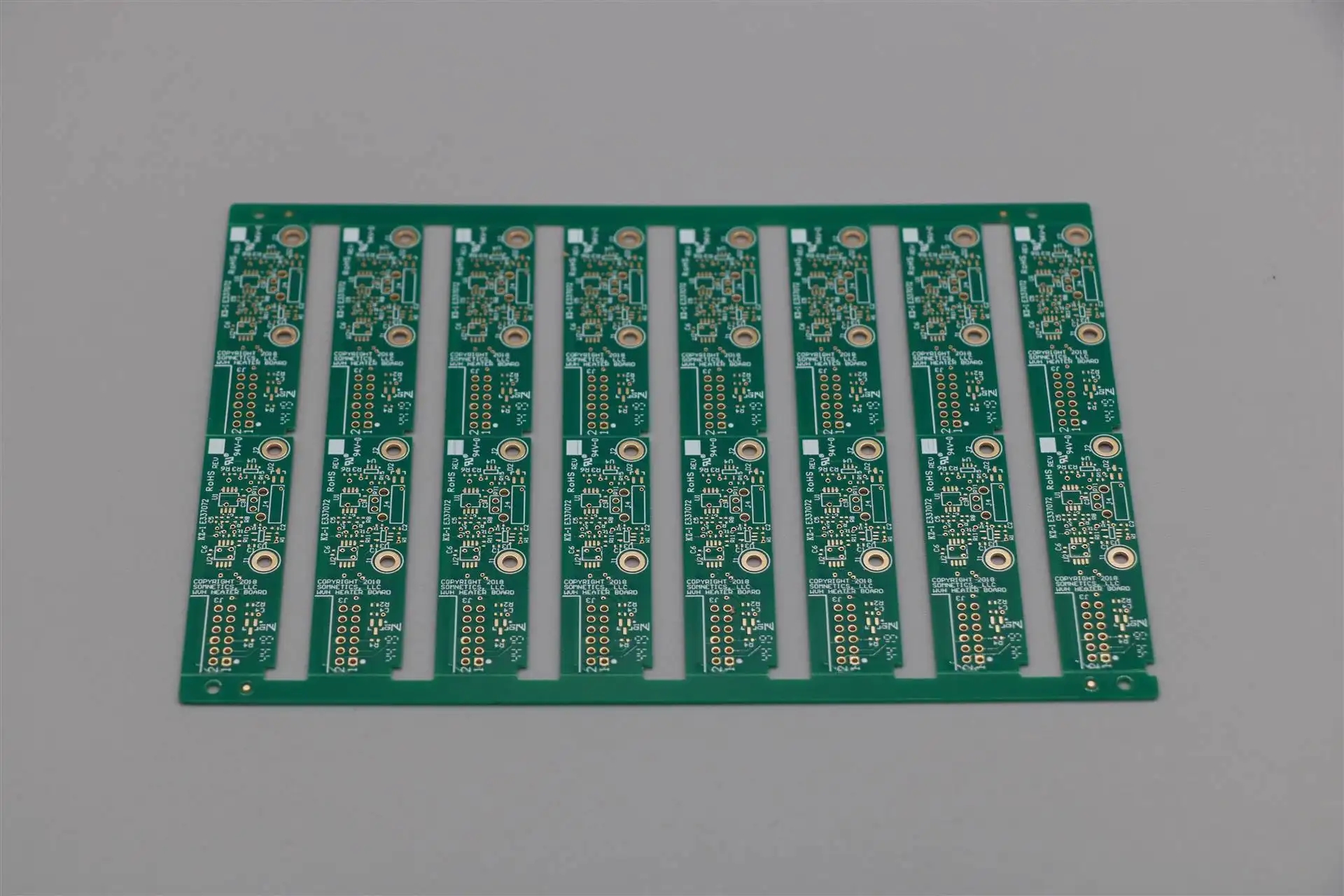

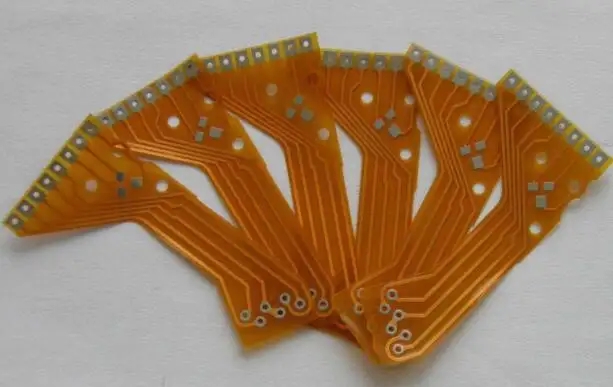

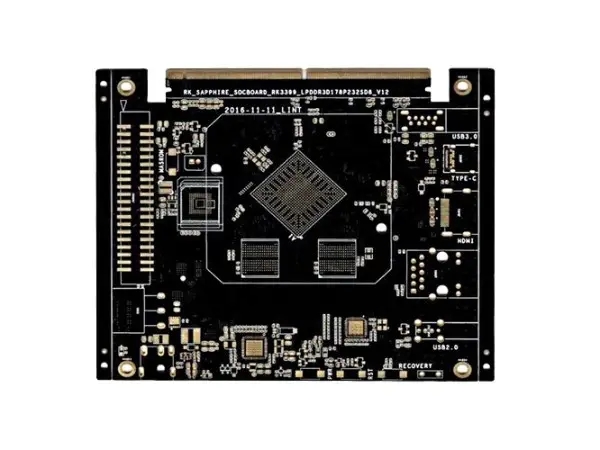

The three proofing paint can also protect electronic products from corrosion like circuit boards The influence of internal factors such as whisker growth and short circuit in electronic system. In general, it is an insulating layer, which is used to ensure that different components do not have problems, leading to early failure of the circuit board. Currently, the process involved in the three proofing paint has gradually developed to use a more complex automatic coating process.

circuit board manufacturers, circuit board designers and PCBA manufacturers explain the development status of the three proofing paint process for electronic engineering circuit boards?

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱