Solution of laser MARKing machine in circuit board industry

PCB is one of the important components of the electronIC industry. The industrial output value accounts for about a quarter of the total output value of electronIC components, which accounts for the largest proportion in each electronic component sub industry. Flexible PCB (FPC) is one of the fastest growing sub industries in the PCB industry. From the perspective of the development trend of various regions in the world, after large-scale restructuring, migration and technology upgrading, doMEStic PCB and FPC production and processing enterprises seized the opportunity to transfer electronic products to China, making the proportion of domestic circuit board output value in the international market further increase.

At the same time, with the development of the circuit board industry, the inkjet printer plays an important role in the production line. In order to prevent counterfeiting in the same industry and effectively manage regional sales, manufacturers will use high-tech anti-counterfeiting means to identify their products. At this stage, enterprises in the industry generally use ink jet printer, and some problems are constantly highlighted, such as high consumption of consumables, high cost, the need for professional maintenance personnel, easy erasure and change of marking effect, and high pollution.

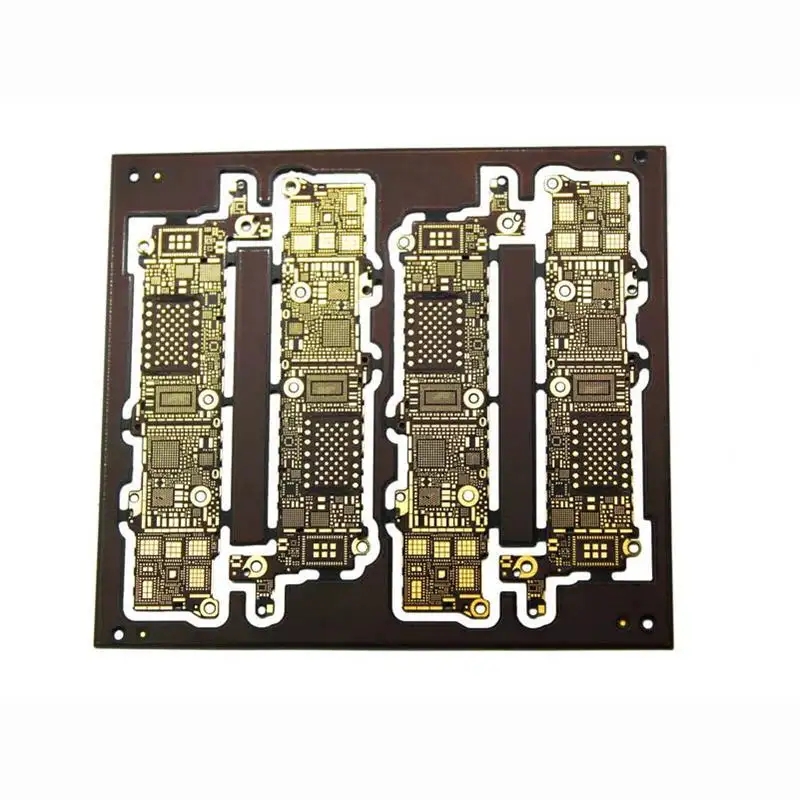

PCB laser marking machine

With people's attention to environmental protection, laser marking has more and more advantages than traditional inkjet marking. Laser marking can process serial numbers and two-dimensional codes to record relevant production information, so as to facilitate the whole process traceability and quality control of electronic products. In PCB industry, the application of laser marking is showing a trend of rapid growth.

The traditional coding method of PCB is to stick label or ink jet mark, which has many disadvantages in the processing process.

Circuit board laser eraser

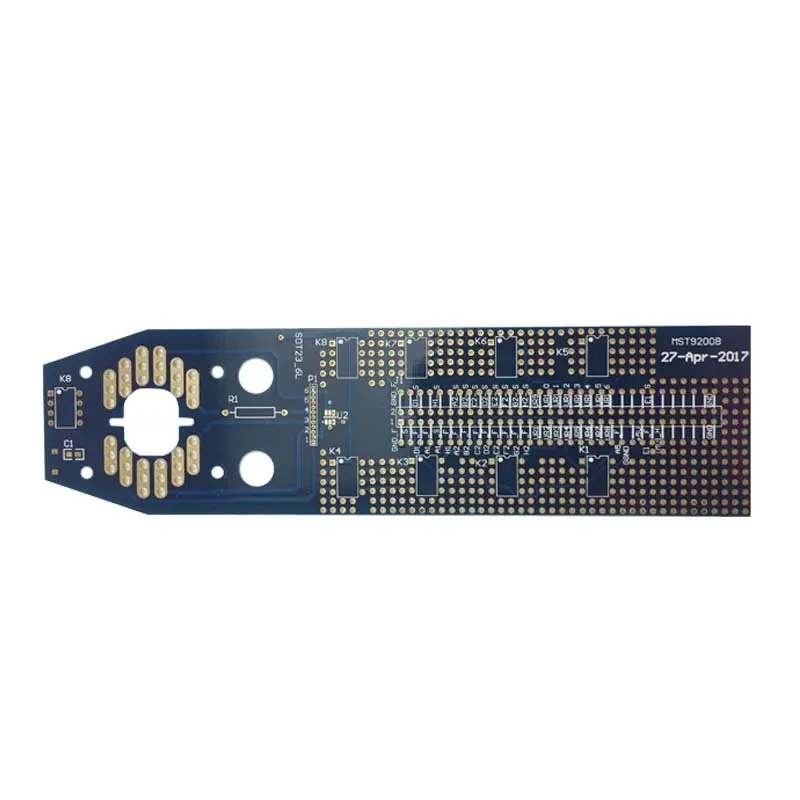

The circuit board laser eraser is a new circuit board cleaning equipment developed by Chuangxiang Laser, which replaces the traditional fiber bar eraser and eraser. The laser plate eraser outputs laser, and then realizes the circuit board cleaning function through the ultra-high speed scanning galvanometer system. It is mainly used to clean the surface of U disk circuit board, CAMera circuit board, card reader circuit board, etc., so that the circuit board has stronger conductivity, better contact, better bonding effect, and the plate cleaning speed is 10 times the speed of traditional manual plate cleaning.

PCB board laser cleaning sample

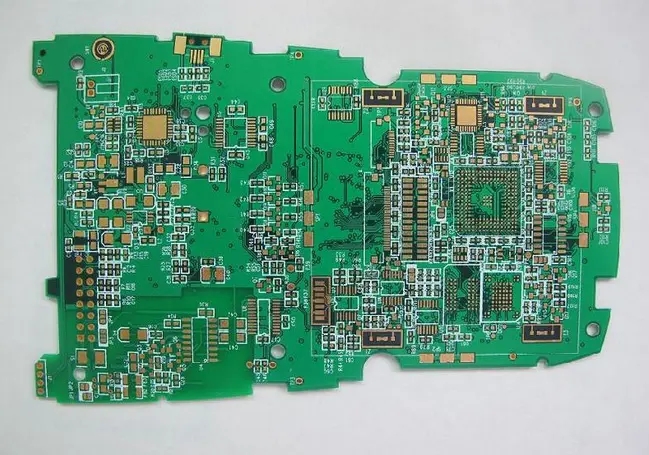

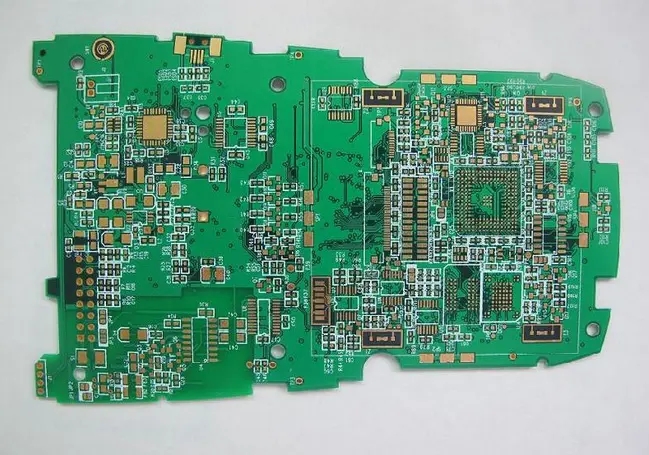

Disadvantages of traditional processing methods:

1. Cleaning by chEMIcal reagents;

Clean with chemical reagents This method pollutes the environment to a certain extent, and there is also a hidden danger that the moisture in PCB substrate cannot be completely removed after cleaning, resulting in short circuit or electric leakage hidden in the products after bonding

2. Manual erasure through manual operation;

Use rubber block or fiber stick to remove manually The disadvantage of this method is that the workers have high work intensity, low enthusiasm and low production efficiency. Especially for PCB after cleaning SMT, the cleaning quality is very unstable and requires a lot of manpower

3. Wipe with automatic equipment such as plate eraser;

The eraser is equipped with round rubber strip or fiber strip erasing method This method uses electric power instead of manual cleaning, which greatly reduces the work intensity of workers; The production efficiency is high, which is more than 3 times higher than that of the way workers use their strength to clean the board; Different cleaning technical parameters can be selected according to different levels of oxide layer and dirt on PCB; Equipped with round rubber strips or fiber strips, the electric plate eraser rotates vertically at high speed to ensure the cleaning quality.

Advantages of laser processing

1. WINDOWS 2000 Chinese operation interface, easy to learn and understand;

2. Accurate CCD image visual teaching enables rapid programming;

3. Any point, 3D straight line, arc and other irregular lines or surfaces shall be wiped continuously;

4. High speed, low-noise speed regulating DC brushless motor makes the wiping effect better;

5. Strong lower dust collection device;

6. Static eliminator can eliminate static electricity within ± 100V;

7. The automatic compensation function of wiping force makes the operation more convenient;

PCB manufacturing, PCB design and PCBA processing manufacturers will explain the solution of laser marking machine in PCB industry.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱