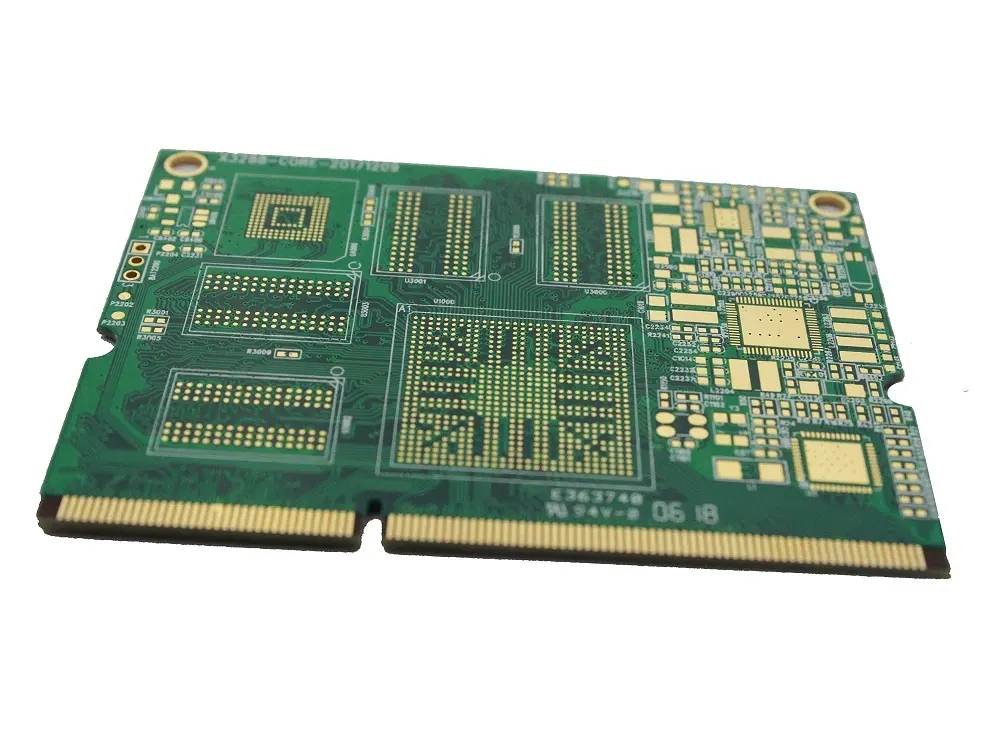

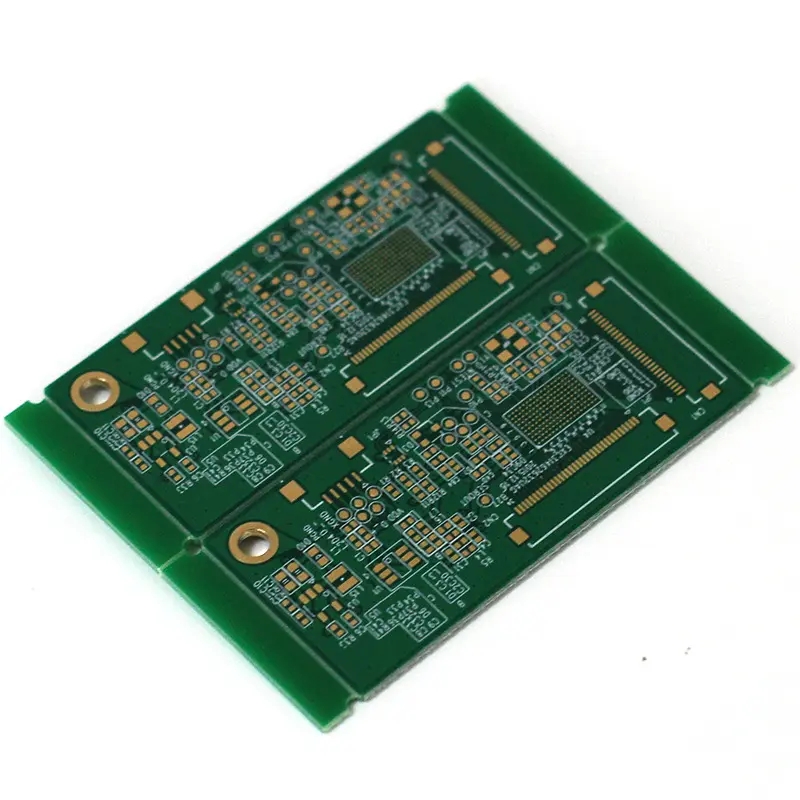

PCB manufacturer: self-made PCB, your PCB is your own

PCB manufacturers, PCB designers and PCBA processors explain to you: PCB manufacturers: self-made PCBs, your PCBs are your own

Corrosion solution is generally prepared with ferrIC chloride and water. Ferric chloride is an earthy yellow solid and easy to absorb water in the air, so it should be seaLED for storage. When preparing ferric chloride solution, generally 40% ferric chloride and 60% water are used. Of course, more ferric chloride is used, or warm water (not hot water, to prevent paint falling off) can make the reaction faster. Note that ferric chloride has certain corrosivity, It is better not to get it on the skin and clothes (it is difficult to wash: - (The reaction container is a cheap plastic basin, which is good for holding the circuit board. Corrosion starts from the edge. When the copper foil without paint is corroded, the circuit board should be taken out in time to prevent the useful circuit from being corroded after the paint falls off. At this time, wash it with clean water, and scrape the paint with bamboo chips and other things (at this time, the paint coMES out of the liquid, which is easier to remove). If it is not easy to scratch, just rinse it with hot water. Then it is wiped dry and polished with sandpaper to reveal shiny copper foil. A printed circuit board is ready. In order to preserve the achievements, Bitbaby usually uses rosin solution to coat the polished circuit board, which can not only facilitate soldering, but also prevent oxidation

Overview of circuit board making methods under amateur conditions

Circuit board is the carrier of electronic circuit. Any circuit design needs to be installed on a circuit board to realize its function. And processing circuit boards is the most headache for amateur electronics enthusiasts. It often takes half a day to design circuits, but it takes several days to process circuit boards. Even some very good circuit design ideas, but because it takes too much time to process the circuit board, they give up the experiment and cannot continue to realize. The stationmaster began to do circuit experiments more than 20 years ago, and the most brilliant thing is to make circuit boards. It can be said that he has tried every means: paint, paraffin, carbon paper, carving knife, even nail polish, eyebrow pencil and other things used by MM, but still can not achieve the goal of making experimental circuit boards efficiently and high-quality.

Later, when I went to the company to engage in professional design and development, I learned that professional engineers did not know there was such a difficulty. They use CAD to design the drawings, print them out and hand them to the PCB processing plant. After a few days, they can get several processed PCB templates. Install the parts, debug and modify them before printing, and then send them to the PCB processing plant for processing. Repeat several times, and the circuit is ready. They do not need to consider all kinds of tedious technological processes and production costs in the process of processing circuit boards. However, the reason why PCB manufacturers have to take the trouble to repeatedly process experimental circuit boards for these companies for free is certainly not to "carry forward the SPIrit of Lei Feng". It is obvious that these processing costs are to be apportioned to the costs of future mass production.

If you are a SMAll unknown company or an individual, the cost of processing may be hundreds of yuan. Therefore, how to process experimental circuit boards with SIMplicity, rapidity, low cost and high quality is a subject worthy of study. Now there are also many new good methods, such as: thermal transfer printing, precoating photosensitive copper-clad, hot-melt plastic film, etc. This website will collect the methods and experiences in this field, compile them into articles, and publish them on this website in succession. Fans, manufacturers, material and equipment suppliers are also welcome to cooperate, or write articles, or provide your products, or cooperate to promote.

As stated in the foreword, the circuit board is the carrier of the circuit, which is commonly referred to as "printed circuit board". The regular production of printed circuit boards is naturally related to printing, and the screen printing process is usually adopted. The basic process is as follows: layout design → tracing → drying the board (making the printing plate) → printing → chEMIcal corrosion → cleaning and surface treatment → printing soldering, MARKing, solder mask and other layers → cutting, punching and other mechanical processing → finished circuit boards. PCB manufacturers, PCB designers and PCBA processors explain to you: PCB manufacturers: self-made PCBs, your PCBs are your own.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱