PCB automation industry enters the era of three-axis robot

PCB manufacturers, PCB designers and PCBA manufacturers explain that PCB automation industry has entered the era of three-axis robots

Nowadays, mobile phones and cars have entered the intelligent industry and the rapid expansion of MARKet capacity has driven the rapid development of the upstream PCB industry. In the process of PCB manufacturers entering the automation and upgrading of SMArt factories, such providers as Powerfly, who are deeply involved in the front-end technology and solutions of PCB industry automation, have played an important role. Especially recently, the three-axis robot launched by Power Flying has set off a new revolution in PCB automation industry with obvious advantages.

PCB industry ushers in a new stage of development

It is observed that the PCB industry is now entering a new stage of development, and many manufacturers in the industry have deeply felt different changes from the past.

First of all, the demand for PCB products has increased signifICantly, allowing PCB manufacturers to see many business opportunities and greater prOSPects. At present, the growing popularity of smart phones and smart TVS, the gradual maturity of intelligent transportation applications in the automotive field, and the introduction of 5G technology into the market have made many industrial enterprises have a huge demand for PCB products. Moreover, the differentiation of different industries also puts forward different requirements for specific PCB products.

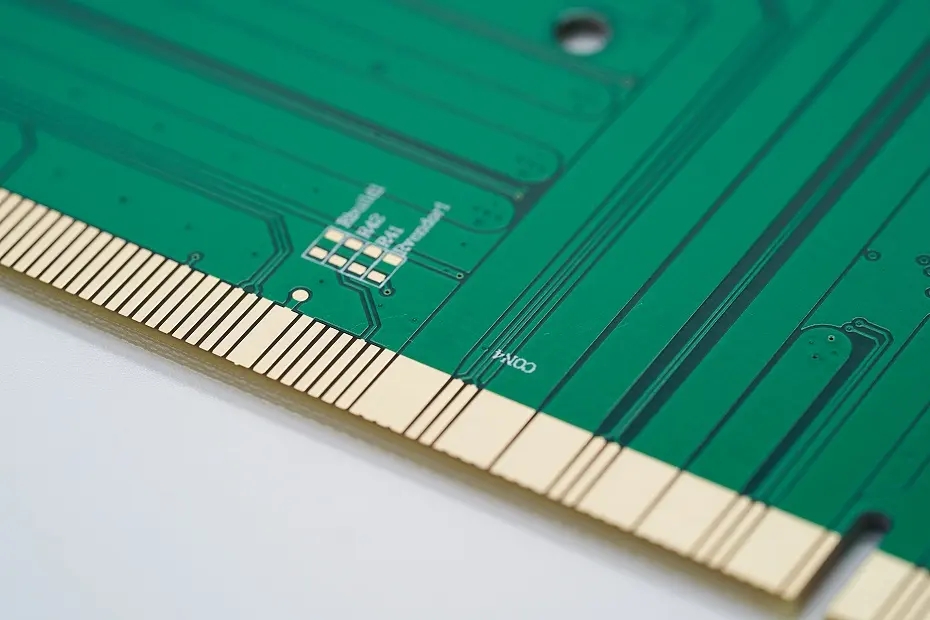

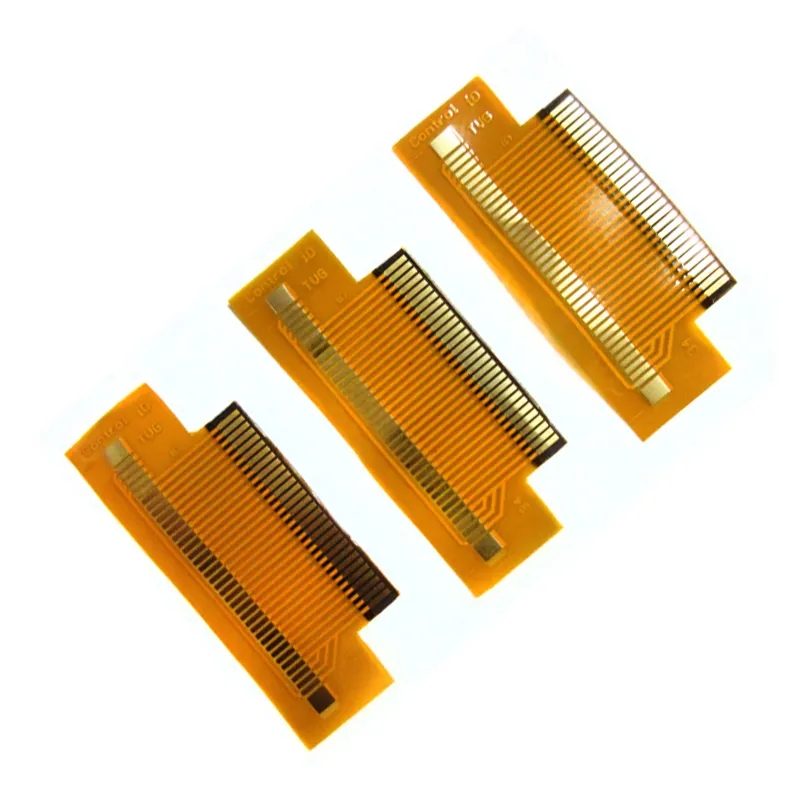

Secondly, the PCB industry itself is progressing. In order to meet the new requirements, the PCB industry has also grown in recent years, and PCB products have shown the characteristics of multi-layer, ultra-thin, miniaturization, high precision, and so on. PCB manufacturers seize the development trend of Industry 4.0, actively introduce robot equipment, promote automation transformation, and strive to build a new generation of smart factory through technological upgrading, achieving new goals such as efficiency, accuracy, and environmental protection.

Thirdly, from the perspective of the current development trend of PCB industry, the global layout of PCB product manufacturing is being redefined, and China has become an important city of PCB industry, accounting for half of the world's output. In the face of such development opportunities, if Chinese PCB manufacturers seize the opportunity, make use of the technological revolution, and through robot equipment, they can and may achieve curve overtaking of global peers, and become a new leader in the development of Industry 4.0.

How many axis robots are more suitable for the current PCB industry

As mentioned above, there are many opportunities in PCB industry, and there are also many technologies and equipment that can be used. However, at present, there is a core equipment in the industry, and we still have different arguments and are still struggling and hesitating. That is, does the robot use six axes, four axes and three axes? The specific problem should be analyzed according to different manufacturers and different needs. Some experts pointed out that comprehensive consideration is required before making a choice.

In most people's opinion, especially when customers come to visit the factory and need to "show" the strength of the company, they think that the more shafts, the more advanced, and the larger the robot equipment, the more powerful. This was the case when robot equipment appeared in the early days. But this understanding is one-sided. In the past, six axis and four axis equipment were generally provided by foreign manufacturers. In order to ensure their own sufficient profits, foreign manufacturers, through technical blockade, paid high fees for robot equipment purchase and later maintenance services. In addition, the operation of the multi axis robot is complex, and the technical requirements for factory operators are also high. Six axis and four axis are suitable for PCB manufacturers with relatively stable orders, but they are not flexible enough to meet the production needs of diversified products of current manufacturers.

The rapid development of 5G, intelligent driving, intelligent terminals and other industries is a great opportunity for PCB industry and manufacturers to achieve greater development, and also a great challenge for how to successfully achieve automation upgrading.

On the one hand, PCB industry and manufacturers should fully recognize the urgency of smart upgrading and put automation and smart factories on the important agenda of enterprise development. On the other hand, we should also learn to calculate accounts according to the actual situation, and rationally adopt appropriate three-axis robot technology and equipment according to the actual situation of the enterprise itself. PCB manufacturers, PCB designers and PCBA manufacturers will explain that PCB automation industry has entered the era of three-axis robots.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱