Test the effectiveness and operation steps of SMT

Test performance index mounting machine

Many people want to take risks or develop into the industry of full-automatIC SMTequipment. We can use the original placement machine for automatic placement, fast and accurate placement. But when we purchase the placement machine, you must test the it performance indicators. We will certainly not buy low-quality, high price machines, so we must know how to detect? Let's introduce our factory:

1. Assembly failure rate: no matter what kind of machine, assembly failure will occur, which is inevitable.

2. The air compression mounter and dry filter system are complete, which fully proves that the machine infrastructure is relatively in place.

3. If we buy the transmission belt of the machine and the chain is worn or aged, it may be a second-hand machine and must be checked.

4. The mounter system can be started and closed normally to ensure the normal operation of its input, output and other system functions.

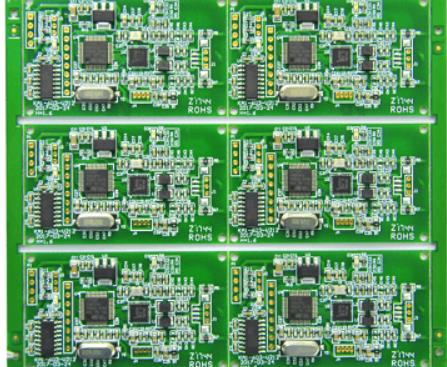

Circuit board

5. The guide rail and the lead screw run smoothly and harmoniously without noise and oil leakage.

6. The appearance of various indicators, buttons and operating handles is complete, and the operation display is normal.

7. The variety, specification, placement direction, base material size and original placement range can be placed according to the specifications and standards.

8. Drive cylinder, solenoid valve, pipeline and gasket shall be free of foreign matter blockage and air leakage. The drive cylinder and solenoid valve work normally without noise.

9. SMT placement speed: Generally, if the IPC is not less than 60% of the rated speed, the IPC is at the normal speed, or the speed we control is not more than 2 tiMES, then we use 1608 components for system testing and assembly at the rated speed. sure

Basic operation steps of the chip mounter

If you want to rapidly produce and assemble components on PCB, we must understand and use SMT mounter. It is not only convenient, fast, accurate and convenient for production, but also discusses the production and operation steps of SMT mounter.

1. Apply solder paste on the PCB to be assembLED, or use the solder paste printer for automatic printing, and then send the PCB coated with solder paste to the SMT mounter for reasonable fixation

2. We install the data in the designated position of the feeder according to the system program settings, so that the mounting head of the mounter can quickly absorb the components.

3. In the system, the control mounting head moves to the position where we want to pick up the parts. At this time, open the vacuum environment in the nozzle to enable the nozzle to absorb and connect components normally.

4. According to the components we want to produce, identify the components and match them in the SMT mounter system. If the component does not meet the standard, we must throw the component into the trash can.

5. According to the settings in the program, adjust the rotation angle of the assembly through the Z axis of the label head, and move the sticker head to the position set by the program, so that the center of the assembly matches the sticker position of the sticker.

6. The nozzle of the SMT mounter will drop to the height set by the program. Turn off the vacuum, and the assembly will drop to complete the assembly mounting operation.

7. After using SMT mounter to assemble components, we need to reset the nozzle position. We will transfer the installed PCB board to the set position interface

Multi functional machines often contact our SMT machine team in the SMT chip industry. If we don't know that the SMT mounter will not work correctly, let me compensate you and introduce the following four important steps: our machine.

1. Patch transportation: the transportation function is an important function of the entire patch automated production workshop. It is mainly responsible for the reasonable transportation of PCB boards through the upper and lower board machines, and can cooperate with SMT mounters to achieve high-speed production functions.

2. SMT pickup: SMT pickup plays a central role in the function of SMT mounter. During the operation of the SMT mounter, the system provides the system with location information and project information to provide the machine with the human head being emptied and pasted to the target position to achieve paper production. In general, learning SMT patches requires the shortest time, and the higher the accuracy is, the key to performance testing.

3. Calibration check: check the errors in the production process for our arrangement and classification After the placement machine is completed, you can select AOI inspection equipment to test and perform PCB assembly test and inspection. When a failure occurs, timely adjustment and solutions enable us to save costs and reduce waste

4. Arrangement and adjustment: After completing all assembly inspection tasks, we can also conduct a second inspection. Under normal conditions, check whether the center of the component matches the center of the SMT mounter installation location, and ensure that the component meets the current installation requirements.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱