SMT patch processing and visual management

1 In surface mounting plants, it is usually to ensure the system operation safety of SMT mounters. The operation of SMT mounters requires not only experienced scientifIC and technical personnel and general management personnel who have received professional knowLEDge training Cooperate with the operation of the machine To ensure high reliability and pass through rate of SMT placement Weld defect rate Good high frequency characteristics. Reduce electromagnetic and RF signal interference It is easy to realize automation and improve production efficiency

2. The comprehensive management stipulates that the temperature of the SMT factory workshop is 25 ± 3 ℃. SMT density is high, and electronic products are SMAll in size and light in weight. The size and weight of SMT chip assembly are only half or even one tenth of that of traditional components. After SMT chips are generally selected for processing, the overall volume of electronic products will be reduced by 4.0% - 60% and the weight will be reduced by 60% - 80% under the corresponding functions.

3. When printing solder paste, it is necessary to prepare the paste tool, steel knife, wiping paper, air flow into the cleaner and mixing knife.

4. In the SMT factory, the main component of solder paste alloy commonly used by most of our companies is tin/lead alloy, and the alloy ratio is 63/37

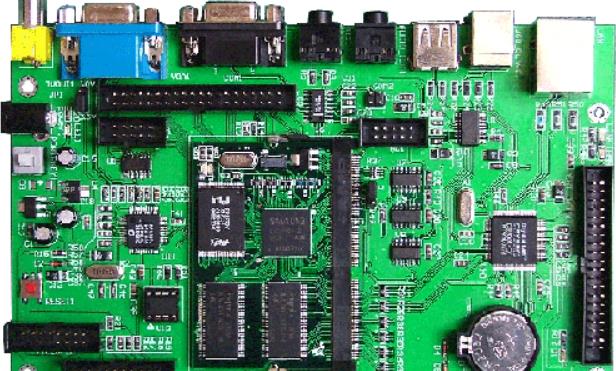

pcb board

The main components of solder paste are divided into two parts: tin powder and flux. Flux is mainly used to effectively remove oxides, destroy the surface tension of molten tin and prevent reoxidation.

5. The volume ratio of tin powder particles to the flux in the solder paste is about 1:1, and the weight ratio is about 9:1. In SMT processing, the solder paste must be thawed and reheated before use Reheating cannot be done by heating

6. The most easily overlooked link in PCBA manufacturing is the storage of BGA and IC chips. The storage of chips shall be packaged and stored in a dry environment to keep the core components dry and anti-oxidation.

Significance of Visual Management in SMT Factory

(1) Improve efficiency

The application of visual management can strengthen communication, so that all personnel can master the company's production, operation and management requirements through visual observation, understand their position and role in the organization, and take correct actions even if they do not know each other specially.

Information flow is a prerequisite for efficient work. If employees can directly obtain operation management information, they can clearly grasp the job requirements and eliminate unnecessary intermediate management links. Some companies have set up many inspectors whose main job is to supervise and inspect the implementation of instructions from the company's superiors. In fact, this is typical of poor management. Whether vertically or horizontally, highly managed enterprises can communicate information smoothly. Visual management is an effective means to achieve smooth information and accurately convey instructions to employees.

The good visual management level of the production site allows managers to have more opportunities to directly obtain on-site work information, making management more realistic. The existence of management at all levels of the company provides necessary support for the production site. Regardless of the instructions given by the management, they should be determined according to the specific needs of the production site. When the management does not know enough about the actual situation of the production site, it will issue some inappropriate instructions to interfere with production activities. The smooth flow of information helps to ensure that the instructions issued by the management accurately reflect the actual situation of the production site and avoid interfering with production activities.

(2) Error prevention

Through visual management, problems and anomalies can be found to prevent errors In the production activities of enterprises, various problems and exceptions occur every day If these problems and exceptions cannot be found and handled in time, normal production activities will be affected Through visual management, it reflects the ideal state and the actual state, or normal state and abnormal state, so that employees can directly feel "different from ordinary" With this kind of pipeline, employees can find problems and anomalies in their work, so that they can find them as soon as possible and formulate countermeasures as soon as possible At the same time, the visual management of the production site allows managers to directly contact the site situation after entering the site, and can see the problems at a glance, so that they can give instructions on the site

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱