Introduction to the importance of post welding cleaning of printed circuit components

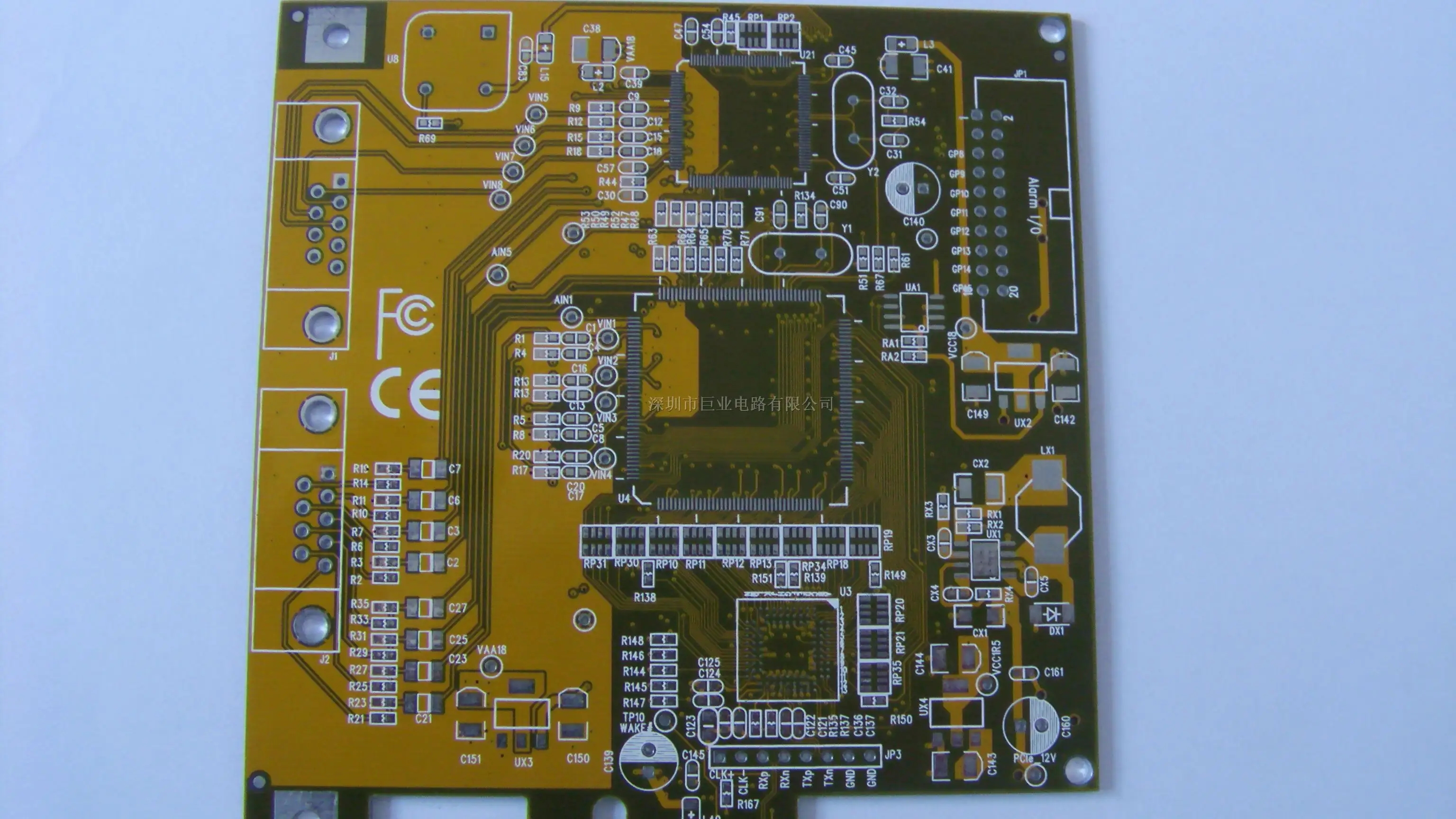

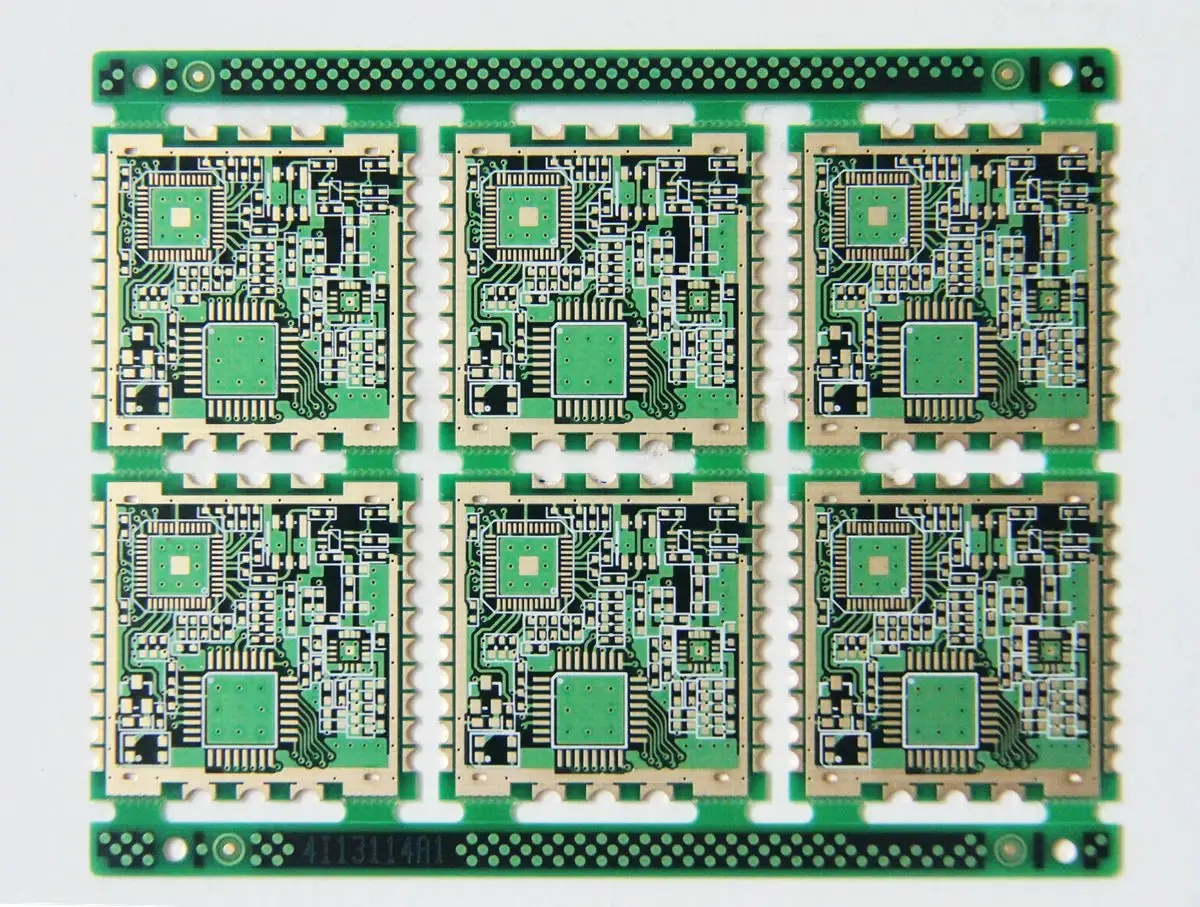

The production process of PCBA (printed circuit assembly) goes through multiple process stages, and each process stage is polluted to varying degrees. Therefore, there are various deposits or impurities left on the PCBA surface of the circuit board (circuit board), whICh can reduce the product performance, or even lead to product failure. For example, during the welding process of electronIC components, solder paste, rosin flux for auxiliary welding, etc., after being processed and welded by SMT chip, obtain residues, which contain organic acid residues and ions. These residual organic acids will corrode the processed PCBA or PCB substrate. The presence of electric ions may cause short circuit, leading to unqualified products.

The production process of PCBA (printed circuit assembly) goes through multiple process stages, and each process stage is polluted to varying degrees. Therefore, there are various deposits or impurities left on the PCBA surface of the circuit board (circuit board), which can reduce the product performance, or even lead to product failure. For example, during the welding process of electronic components, solder paste, rosin flux for auxiliary welding, etc., after being processed and welded by SMT chip, obtain residues, which contain organic acid residues and ions. These residual organic acids will corrode the processed PCBA or PCB substrate. The presence of electric ions may cause short circuit, leading to unqualified products.

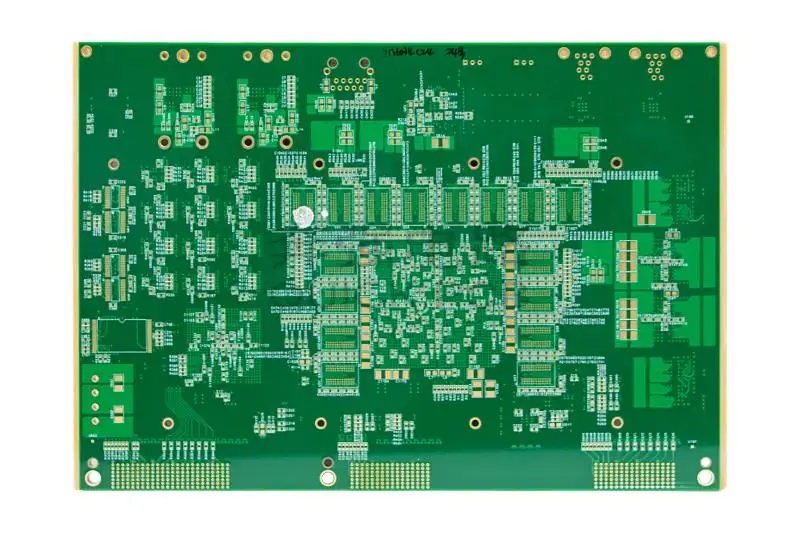

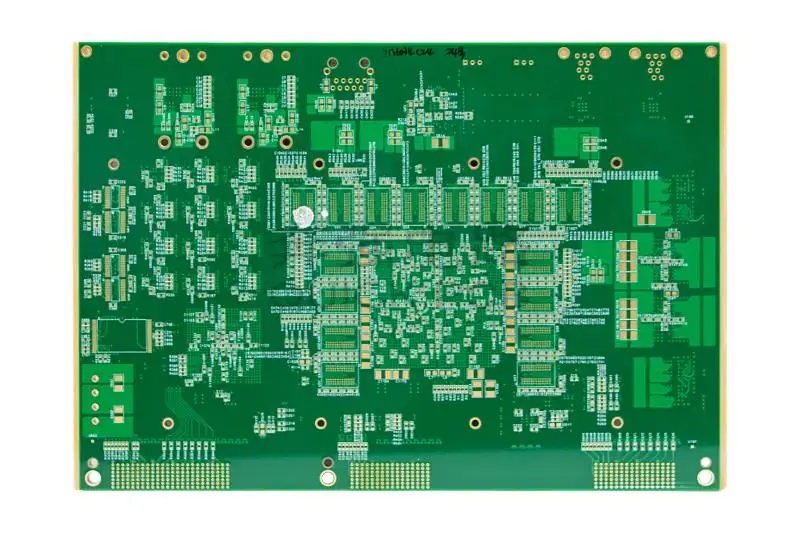

Because we pay attention to all kinds of quality control in SMT chip processing in daily life, but ignore the cleaning process after PCBA manufacturing. Most enterprises do not attach great importance to the cleaning process and think that cleaning is not a key technical step. However, the invalidity caused by the pre cleaning of problematic products that have been used on the client for a long time has LED to many failures, and the maintenance or recall of products has led to a sharp increase in operating costs.

Introduction to the importance of post welding cleaning of printed circuit components

Ionic pollution and non-ionic pollution are always important pollution sources on PCB and PCBA circuit boards. Ion pollutants enter into contact with water in the environment, electrochEMIcal migration occurs after electrification, and the dendritic structure is formed, leading to the path of low resistance and the destruction of PCBA function of the circuit board (PCB). Non ionic pollutants can penetrate the insulation layer of PCB and form dendrites under the surface layer of pcb board. In addition to ionic and non-ionic pollutants and particulate pollutants, such as solder balls, solder bath floats, dust, dirt, etc., these pollutants will lead to low solder joint quality, pores, short circuits, and many other undesirable phenomena in welded joints.

Because soldering flux or solder paste can be widely used in reflow soldering and wave soldering processes in the current SMT chip processing in China. They are mainly composed of solvents, wetting agents, resins, corrosion inhibitors, activators and other effective ingredients. Thermal modification products will inevitably develop after welding. These enterprise material cultures dominate the MARKet in all pollutants. From the perspective of product structure failure analysis, The residue after welding is the most important social factor affecting the company's product service quality management. The residue of rosin resin is easy to absorb dust or impurities, causing students to contact a resistance that gradually increases. In serious cases, it may lead to our open circuit failure. Therefore, strict cleaning must be carried out after welding, and the quality of (circuit board) PCBA must be improved.

To sum up, the cleaning of PCB (circuit board) PCBA is very important, and "cleaning" is an important process, which is directly related to the quality of the circuit board (circuit board).

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱