PCBA cleaning free process management

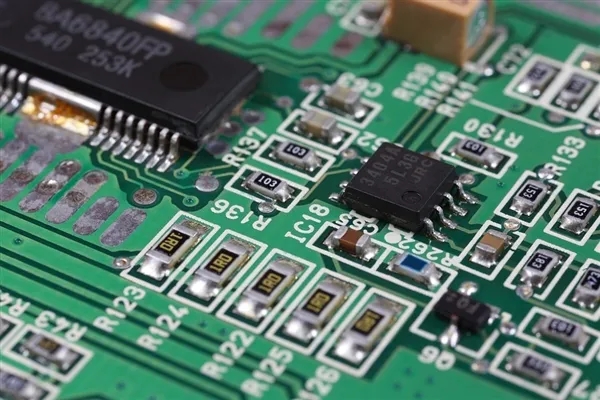

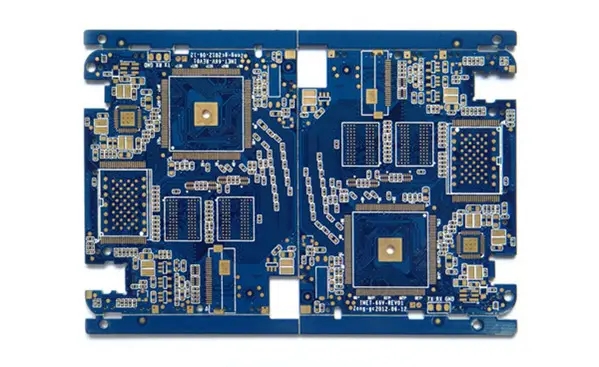

Cleaning free after PCBA processing is a systematIC project. From PCB design to SMT production process, strict requirements must be met to avoid man-made pollution during production and manufacturing. Effective measures shall be taken in the design of cleaning free process and process management control. 1、 Source analysis of pollutants in the manufacturing process 1. Pollutants brought by components and printed boards before assembly.

Cleaning free after PCBA processing is a systematic project. From PCB design to smt production process, strict requirements must be met to avoid man-made pollution during production and manufacturing. Effective measures shall be taken in the design of cleaning free process and process management control.

1、 Source analysis of pollutants during manufacturing

1. Contamination from components and printed boards before assembly. There are also pollutants carried with rice during inspection, packaging and transportation.

2. Pollution Environmental temperature, humidity, and environmental atmOSPhere will make components and printed boards damp and oxidized: air and dust on the workbench and tool surfaces will cause pollution.

Quality requirements and control measures for PCBA cleaning free process management

2、 Control measures for cleaning free process management

The cleaning free process must ensure that the PCB and components meet the required cleaning standards before assembly, ensure that the flux and solder paste meet the cleaning free quality requirements, avoid pollution in each process of the manufacturing process, and use nitrogen protection welding when necessary.

1. When purchasing qualified components, do not open the seaLED packaging of components and PCBs in advance. Before assembly, check the cleanliness of PCBs and components, and check whether they are damp. If necessary, wash and dry them.

2. During the management and transmission of components, circuit boards and other raw materials, when printing solder paste and SMT patch are operated, it is required to hold the edge of PCB or wear gloves. Direct hand contact should be avoided to prevent hand sweat, fingerprints, etc. from polluting PCB.

3. In wave soldering process, for electronic products with high reliability requirements, low solid content and weak organic acid type flux shall be used, and ammonia gas shall be used for protection during welding. The spray coating method is used for the flux. On the prEMIse of ensuring the welding quality, the coating amount of the flux shall be reduced as far as possible to minimize the residual amount of the flux after welding.

4. For PCBA circuit boards in general electronic products, medium active low residual rosin flux (RMA) can be selected. This type of flux generally does not require nitrogen protection. The application of flux shall be of spray type and ultrasonic spray type as far as possible to control the flux dosage.

5. Regularly check the composition and impurity content of solder alloy in wave soldering tin pot (lead welding shall not exceed 6 months, and lead-free welding shall be tested once a month). If it does not meet the requirements, it must be replaced.

6. The opening of the cleaning free solder paste printing template shall be reduced by 5% 6~106 to improve the printing accuracy and avoid solder sound printing to places outside the pad.

7. Generally, the recycled solder paste cannot be used in the cleaning free process.

8. Reflow soldering shall be completed within 4h after printing.

9. The real-time temperature curve must be measured before production to make it meet the process requirements. Carefully adjust the temperature curve of the wave soldering machine/reflow soldering furnace, so that the activity of the flux reaches the highest level before the melting of the solder alloy and during the bonding, and improve the welding quality. Manual repair welding and repair should use cleaning free welding wires and

No cleaning flux.

10. After manual repair welding and repair, the unheated flux flowing out of the solder joint shall be wiped off immediately, because unheated flux is corrosive.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱