What role does QC play in PCBA processing?

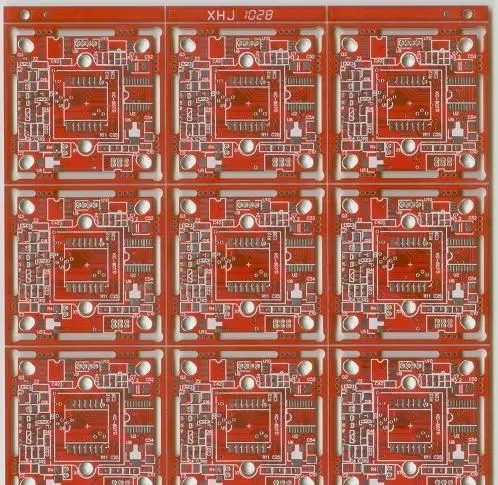

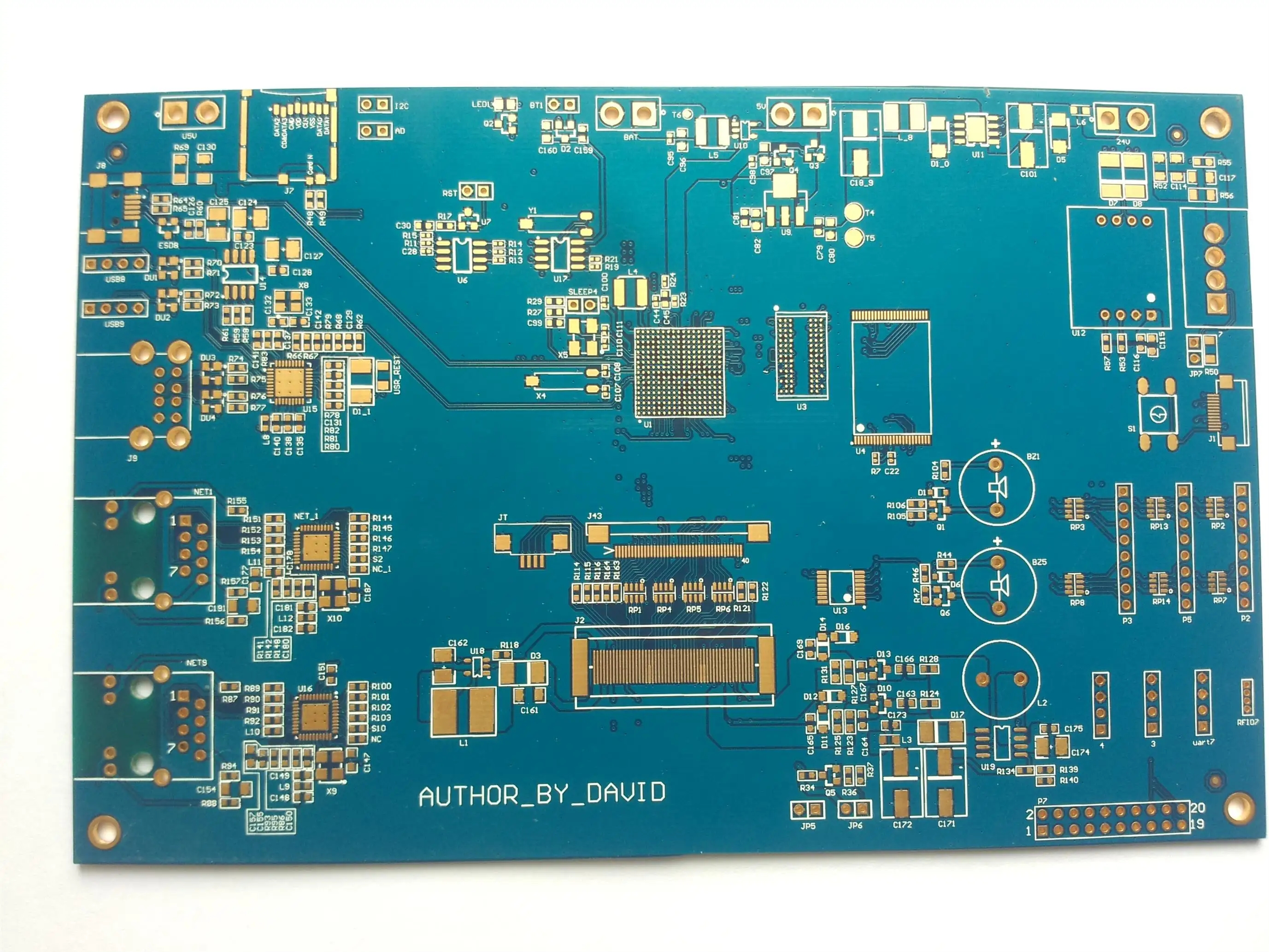

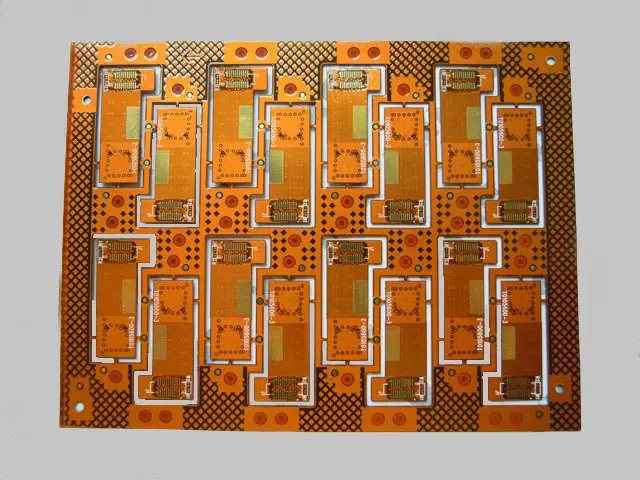

PCBA processing is to connect various electronIC components on PCB board through surface mount (SMT), plug-in (DIP) and other electronIC assemblies. PCBA process flow mainly includes SMT, AOI, DIP, FCT testing and other processes. Due to the size difference of electronic components, there will be different processes and requirements in assembly and insertion. The assembly density of PCBA is relatively high, and the SMAll size and light weight of electronic products also have certain changes and requirements in mounting. Among them, the reliability, seismic resistance and excellent weldability of the products have high requirements for the hardware and software facilities of PCBA processing

Quality is the sum of the attributes of various elements to meet customer needs. In the PCBA process, quality is an important factor that affects the reputation and reputation of the enterprise and whether customers are willing to continue to cooperate. The sum of characteristics and features that reflect the entity's ability to meet the user's explicit or implicit needs. In the PCBA process, quality requirements can generally be divided into six categories: A performance requirements: physical characteristics, functional inspection, materials and their service life; B Applicability requirements: customer needs and the applicability of PCBA board functions; C Reliability requirements: reliability of finished PCBA board; D Safety requirements: the customer shall use it reliably and timely, and cannot use it

Quality is the sum of the attributes of various elements to meet customer needs. In the PCBA process, quality is an important factor that affects the reputation and reputation of the enterprise and whether customers are willing to continue to cooperate. The sum of features and characteristics reflecting the entity's satisfaction with the user's explicit or implicit needs

The quality requirements in the PCBA process can generally be divided into six categories:

A Performance requirements: physical characteristics, functional inspection, materials and their service life;

B Applicability requirements: customer needs and the applicability of PCBA board functions;

C Reliability requirements: reliability of finished PCBA board;

D Safety requirements: customers should use it reliably and timely, without causing injuries and accidents to users;

E Economic requirements: applicability, customer affordability requirements;

F Requirements for appearance and aesthetics: customers' psychological feeling and aesthetic value, PCBA boards should be clean and beautiful.

production process Inspection (IPQC): generally refers to the quality control of production activities in each stage from the warehousing of materials to the warehousing of finished products, namely, Inprocess Quality Control. The quality inspection at this stage is calLED FQC (Final Quality Control).

QC

The purpose of in-process inspection is:

A. Before mass production, find defects in time and take measures,

It can prevent a large number of defective products

B. In view of the non opportunity change factors of quality, during the operation process, check to prevent the occurrence of defective products (the process inspection shall not only inspect the products, but also verify the main process elements that affect the product quality (such as 5MIE). In fact, during the normal production of mature products, any quality problem can be attributed to the variation of one or more elements in 5M1E)

C. Through the implementation of inspection, the defective products in this process are not allowed to flow into the next process, so as to prevent the unqualified products from flowing into the next process for further processing

In the PCBA process, QC is very important, which plays a vital role in the yield of materials, electronic components and finished products. SometiMES we may complain that there are too many QC quality inspection steps in the processing process, which is troublesome and time-consuming, and we want to omit various processes, but these are not allowed. Only when we strictly implement each step in the production can we deliver the finished products that customers are satisfied with.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱