Process composition and description of SMT production line

SMT, the full name of SMT, is SMT in Chinese Various types of electronIC components are instalLED on the PCB lamp board After welding, the subsequent inclination, test and inspection functions become the final product - PCBA

Let me introduce the SMT production line process and related equipment, as well as the functions and functions of each equipment, so that you can have a preliminary understanding of SMT

1. Program design and debugging of chip mounter

According to the sample BOM patch location map provided by the customer, program the coordinates of the PCB pad where the patch electronIC components are located. The purpose of programming is to let the mounter know which pads should be connected to which electronic components, then compare the first one with the SMT chip processing data provided by the customer, and then continue the subsequent production after confirming that it is correct.

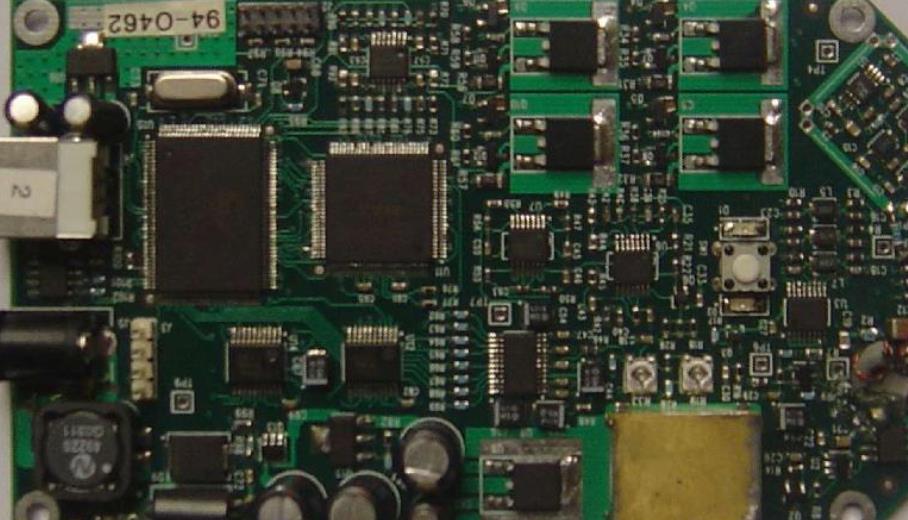

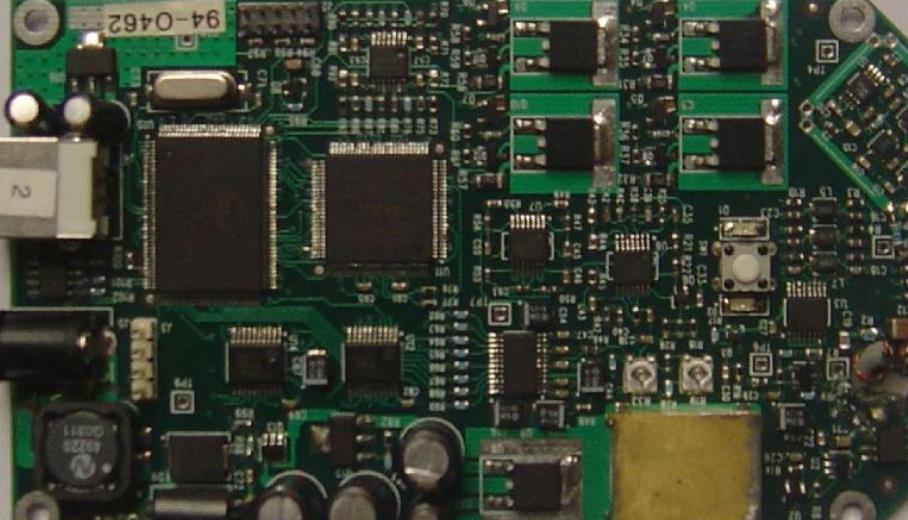

Circuit board

2. Printing solder paste

Solder paste is printed on PCB board, and components need to be welded with molds The main purpose of solder paste is to paste electronic components onto PCB pads Solder paste is SIMilar to toothpaste. Its main components are tin powder and flux, which are used to prepare parts for welding The equipment used is a solder paste printer

3.SPI

The solder paste detector detects whether the solder paste printing is a good product and whether there are any undesirable phenomena, such as less tin, leakage and excess tin. It is captured by the CAMera, then displayed on the computer, and then calculated by the system to determine whether the results are bad.

4. Chip mounter

The electronic components are accurately installed on the fixed position of the PCB. The placement machine is divided into high-speed machine and general-purpose machine

High speed machine: used to connect large and SMAll parts with pin spacing; Universal machine: connecting small pin spacing (dense pins), large volume components (usually called large data, special-shaped parts, such as covers and connectors), components with different rules, etc.).

5. Reflow soldering

The main purpose is to melt the solder paste at high temperature, and after cooling, make the electronic components and PCB board firmly welded together. The equipment used is reflux furnace. Reflow soldering is generally divided into ordinary reflow soldering, nitrogen reflow soldering and vacuum reflow soldering. There are mainly four temperature zones, namely preheating zone, constant temperature zone, welding zone and cooling zone. The furnace temperature curve of reflow welding must be set reasonably.

6.AOI

Automatic optical detector is used to detect whether the welding parts are poorly welded, such as tombstone, displacement, empty welding, connecting bridge, etc.

7. Manual visual inspection

Manual visual inspection is mainly used to detect PCBA false alarms through AOI, because AOI is unable to detect all welding defects completely and accurately at present, and false alarms will occur due to various situations, that is, plates that are normally welded are reported as welding problems by mistake. A manual visual inspection is required to recheck. Determine if the board is really bad.

8. Packaging

Qualified products will be packaged separately The commonly used packaging materials are anti-static bubble bags, electrostatic cotton, and plastic trays There are two main methods of packaging One is to use anti-static bubble bags or static cotton to roll and package separately, which is the most commonly used packaging method at present; The other is customized blister tray according to the size of PCBA Put the package into the blister tray, which is mainly used for SMD components with PCBA board sensitive to needles and easy to damage

Summary

surface mount is one of the most popular assembly methods of electronic products. SMT equipment has experienced the development process from manual to sEMI-automatic and then to fully automatic, and its accuracy has been improved from the previous millimeter level to the current micron level. Surface mount components are gradually developing in the direction of light, thin, short and small.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱