Surface Roughness Assembly Method and Mounter Control

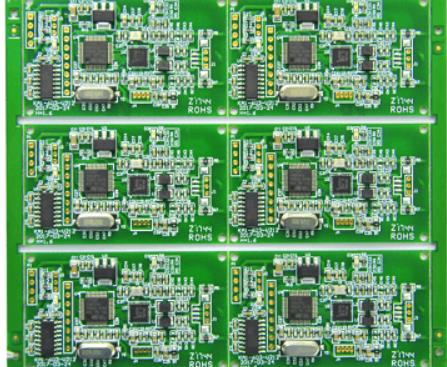

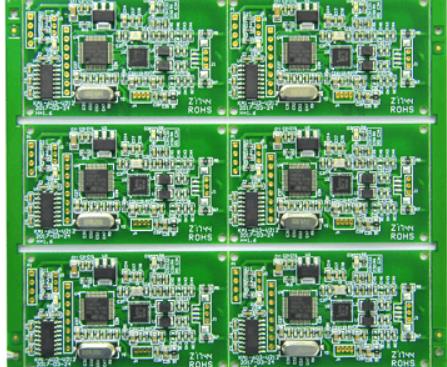

SMT chipprocessing is one of the most popular skills and processes in the electronic assembly industry. With the electronIC products becoming SMAller and lighter, the functional requirements become higher and higher The SMT process has also become increasingly MESsy

Surface Mount Technology can be divided into single-sided assembly, double-sided assembly, single-sided mixed assembly and double-sided mixed assembly according to the assembly method.

(1.) Single side assembly process: as long as the surface is instalLED on one side. The process is as follows:

Printing solder paste=>Installation components=>Reflow soldering

(2) Double side assembly process: as long as the double-sided installation surface is mounted. The process is as follows:

-Level B side printed solder paste=>Side B installation component=>Side B reflow soldering=>Turnover rate=>Side A printed solder paste=>Side A installation component=>Side A reflow soldering

(3) Single side hybrid assembly process: THC is located on the A side, and SMC is located on the B side There are usually two single-sided mixed assembly processes: the first pasting method and the second pasting method The former has low cost and SIMple process; The latter has a chaotic process.

The first pasting method: B surface dispensing=>B surface mounting components=>B surface glue curing=>Flaps=>A. Surface bonding components=>B surface wave soldering

Rear connection method: A. side insert component=>valve=>B side distribution=>B side installation component=>B side glue curing=>B side wave soldering

(4) Double sided mixed assembly process: The double sided process is quite chaotic, THC, SMC/SMD can be single sided or double sided.

Process 1: Print solder paste on A. side=>Install components on A. side=>Insert components on A. side=>Wave soldering on B side

Step 2: Print solder paste on side A=>Install components on side A=>Reflow soldering on side A=>Valve=>Distribute components on side B=>Install components on side B=>Cure glue on side B=>Valve=>Insert components on side A=>Wave soldering on side B

Process 3: one side dispensing=>A Side installation component=>glue curing=>flip plate=>printed solder paste on side B=>side installation component=>inserted component on side B=>reflow soldering=>flip plate=>inserted component on side A=>wave soldering on side B

The process of SMT seems to be very messy. Single side assembly, double side assembly and single side hybrid assembly are all well understood. Double side hybrid assembly is very difficult. In fact, the classification is not messy. The double-sided mixed assembly process 1. is very simple, process 2. is the most commonly used, and the method is also the most reliable. Process 3. is rarely used, and B-side components need to undergo secondary welding.

According to actual production experience, reflow soldering is generally used for products without third-party components; Two types of reflow soldering are generally B side reflow soldering; Reflow soldering and wave soldering are both first reflow soldering and then wave soldering, and wave soldering is generally B side.

Surface Roughness Processing Knowledge for SMT Machine Development and Control

SMT is a very important process in SMT machining. The surface roughness mounter will naturally be highly valued by manufacturers and customers, but many people may not understand the development and control of the surface roughness mounter. Now let's share these basic knowledge with you.

1. Development of mounting machine

In the surface roughness assembly equipment, the mounting machine is the most messy system. It focuses on automatic control, electromechanical integration skills, optical measurement skills, computer-aided design and production of computer-aided design/CAMs and other skills. The development of SMT machine completely follows the development of electronic component packaging situation, the development of electronic products and the development of electronic product manufacturing industry.

Its development and changes are mainly shown in the following aspects:

1. The size of SMCs is getting smaller and smaller; The distance between integrated circuit pins is getting smaller and smaller; The assembly density of polychlorinated biphenyls is increasing;

2. There are more and more types of electronIC components on PCBs; The assembly control precision is required to be higher and higher; The production speed is required to be faster and faster;

3. Changes in process skills led to the following situations: stacking (PoP) assembly, foot/square foot assembly of flexible printed circuit boards (coffee), 3D multi chip assembly 3D-MCM, wafer bread on board, etc.

2、 Chip mounter classification

1. SEMI automatic placement machine: used for the trial production of small batch placement products in the laboratory

2. Medium speed mounter: commonly used in small and medium-sized batch production enterprises

3. High speed mounter: used for large and small enterprises

4. Multi function mounter: it can be used for small batch and various types of production lines

5. Equipped with medium and high speed machines to form a flexible production line

6. Special component placement machine: It is specially used for placement of special electronic components such as high-frequency circuit masks, connectors, integrated circuit card sockets, etc.

The stability and accuracy of the system The quality of the surface roughness placement machine will directly affect the placement quality, and then affect the stability and accuracy of the final product operation We have always attached great importance to product quality, surface roughness and product quality are the basis for enterprise development Japan's Zhuki language chip mounter was launched in the country for the first time The minimum placing component reaches 0.2mm * 0.1mm It can stack more than ten sesame sized components without dropping, and the surface roughness is the most basic and important from The placement process is guaranteed

The above is the explanation given by the editor of PCB circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱