SMT disassembly and raw material quality inspection

Disassembly tips SMT patch components

In general, it is not easy to remove smt patch components. Mastering it requires constant practICe. Otherwise, it is easy to damage the SMD components if they are forcibly disassembLED. Of course, mastering these skills requires practice

In general, it is not so easy to remove the SMT chip processing components. Mastering it requires constant practice. Otherwise, it is easy to damage the SMD components if they are forcibly disassembled. Of course, mastering these skills requires practice. It can be roughly described in three cases.

1. For components with fewer smd components, such as resistors, capacitors, diodes, transistors, etc., first tin a bonding pad on the PCB, then use tweezers to fix the components to the installation position, and use the left hand to close them to the circuit board. Use your right hand to solder the pins on the tin pad with a soldering iron. You can loosen the left tweezers and solder the remaining feet with tin wire. If you want to remove such parts, it is easy to use a soldering iron to heat both ends of the parts at the same time, and then gently lift the parts after the tin melts.

2. A SIMilar method is used for components with more pins for smt chip processing, and for chip components with larger spacing. First, tin a bonding pad, then clamp the assembly with tweezers, weld one foot with the left hand, and then weld the remaining feet with tin wire. It is usually better to remove such components using a hot-air gun. One hand holds a hot air gun to blow the solder, and the other hand uses tweezers and other clamps to remove the components when the solder melts.

3. For components with high pin density, the welding procedure is similar, that is, first solder one pin, then solder the rest of the pins with tin wire. The number of pins is relatively large and dense, and the alignment of pins and pads is the key. Generally, pads with only a SMAll amount of tin on the corners are selected. Use tweezers or hands to align the component with the pad, align the edge with the pin, press the component on the PCB with slight force, and then weld with a soldering iron. The corresponding pins of the magnetic disc are well welded. Do not shake the circuit board with force, but gently rotate the circuit board, and then solder the pins to the rest of the corners. After welding the four corners, the assembly will not move, and the remaining pins will be welded one by one. When welding, first apply some pine perfume, and then apply a small amount of tin on the tip of the soldering iron to weld one pin at a time.

Finally, it is recommended to mainly use a hot air gun to remove high pin density components, clamp the components with tweezers, blow all pins back and forth with a hot air gun, and lift the components when they are completely melted If more parts need to be disassembled, try not to face the center of the parts when blowing, and the time should be as short as possible After removing the components, clean the PCB pad with a soldering iron

Tasks and Methods of SMT Raw Material Quality Inspection

The task of raw material quality inspection includes four aspects: raw material quality judgment, quality problem prevention, quality information feedback and quality problem arbitration. Quality judgment refers to judging the qualification or quality level of raw materials through testing according to relevant quality requirements and specifications. Quality problem prevention refers to the use of quality inspection to ensure that unqualified raw materials are not put into use, so as to prevent the resulting quality problems. Quality information feedback refers to the feedback of quality problems in raw materials to relevant departments or cooperative enterprises through quality inspection, so as to find out the causes of quality problems in time and provide basis for improving quality. Quality arbitration refers to the use of scientific quality inspection and evaluation methods to determine the causes and responsibilities of quality problems when raw material suppliers and receivers have complaints or disputes about quality problems.

Research methods SMT raw material quality inspection includes sensory inspection, electrical inspection, and test inspection Sensory test refers to the test using human sensory organs as test tools to evaluate the quality of raw materials It is mainly used for qualitative detection of product appearance, color, scar, SMEll, and other visual and external contents Instrument testing refers to the use of instruments, measuring tools, testing equipment and other testing tools that use physical or chEMIcal methods to test product quality characteristics, such as physical and chemical properties of soil SMT raw materials such as efficiency, strength, hardness, and reliability Trial use refers to identifying the quality or characteristics of raw materials through actual use This test method is mainly used to determine the quality of new materials

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

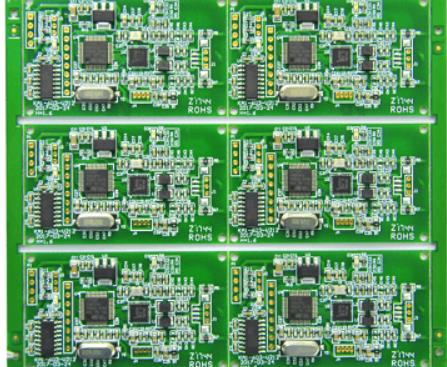

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱