鑫景福致力于滿足“快速服務,零缺陷,輔助研發”PCBA訂購單需求。

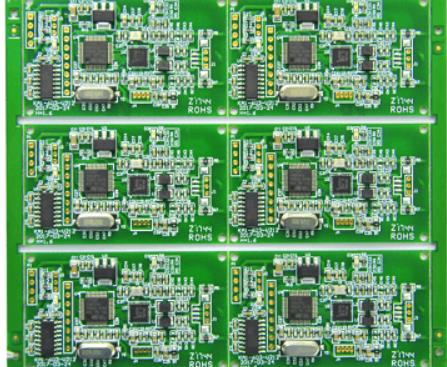

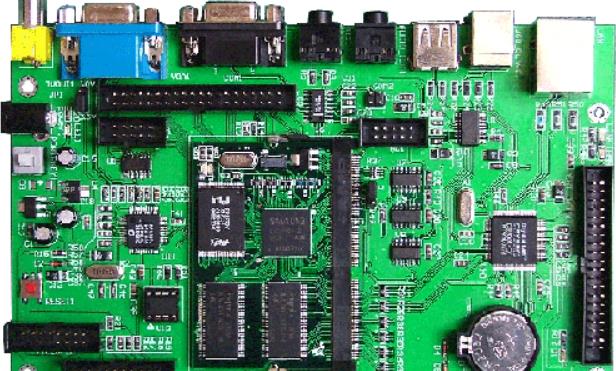

PCBA加工

SMT solder paste is easy to dry and bridge

SMT patch processing is easy to dry

Solder paste is a kind of soldering material produced with the SMT chip processing industry It is a paste solder, whICh is uniformly mixed with alloy powder and paste flux carrier Many SMT chip processing manufacturers report that solder paste is easy to dry during production Next, we will introduce the causes and solutions of solder paste drying easily

On the one hand, the solder paste is only used in a SMAll area during reflow soldering, which is easier to dry than the solder paste in the solder paste box. At this time, the solder paste does not melt, and the flux cannot cover the solder joint, resulting in poor solder joint. At the same time, a small amount of solder paste is easier to heat transfer, while high temperature actually makes solder paste more difficult to melt. Therefore, we can properly adjust the reflow temperature curve to solve this problem, or welding in nitrogen environment is a good way to solve this problem.

In addition, the use environment, humidity, temperature and other external factors of solder paste will affect the drying and non melting of solder paste in the use process, so we should also pay attention to these external factors. I hope these methods can solve your problems.

Reasons and Solutions of Bridging in SMT Processing

1. Solder paste quality problems

The metal content in the solder paste is relatively high, especially after a long time of printing, the metal content tends to increase, resulting in IC pin bridging;

Solder paste has low viscosity and diffuses to PCB pad after preheating;

After preheating, it diffuses to the bonding pad, and the solder paste is poorly decomposed.

Solution: Adjust the solder paste mixture or use good solder paste.

2. Printing machine system problems

The printer has poor repeatability and unexplained alignment (poor alignment of the steel plate, poor alignment of the PCB), which causes the solder paste to be printed outside the pad. This is usually seen in the production of fine QFP;

The size and thickness of the PCB window are not designed correctly, and the tin lead alloy coating in the PCB pad design is uneven, resulting in excessive solder paste.

Solution: Adjust the printer to improve the coating of PCB pads.

3. Installation problems

Excessive solder paste pressure and diffusion flow after solder paste compression are common causes in production. In addition, the placement accuracy is not enough, components will shift, IC pins will deform, etc., which is easy to cause bridging.

4. Preheating problem

The heating speed of the SMT reflow oven is too fast, and there is no time for the solder paste solvent to evaporate

SMT patch processing is easy to dry

Solder paste is a kind of soldering material produced with the SMT chip processing industry It is a paste solder, whICh is uniformly mixed with alloy powder and paste flux carrier Many SMT chip processing manufacturers report that solder paste is easy to dry during production Next, we will introduce the causes and solutions of solder paste drying easily

On the one hand, the solder paste is only used in a SMAll area during reflow soldering, which is easier to dry than the solder paste in the solder paste box. At this time, the solder paste does not melt, and the flux cannot cover the solder joint, resulting in poor solder joint. At the same time, a small amount of solder paste is easier to heat transfer, while high temperature actually makes solder paste more difficult to melt. Therefore, we can properly adjust the reflow temperature curve to solve this problem, or welding in nitrogen environment is a good way to solve this problem.

In addition, the use environment, humidity, temperature and other external factors of solder paste will affect the drying and non melting of solder paste in the use process, so we should also pay attention to these external factors. I hope these methods can solve your problems.

Reasons and Solutions of Bridging in SMT Processing

1. Solder paste quality problems

The metal content in the solder paste is relatively high, especially after a long time of printing, the metal content tends to increase, resulting in IC pin bridging;

Solder paste has low viscosity and diffuses to PCB pad after preheating;

After preheating, it diffuses to the bonding pad, and the solder paste is poorly decomposed.

Solution: Adjust the solder paste mixture or use good solder paste.

2. Printing machine system problems

The printer has poor repeatability and unexplained alignment (poor alignment of the steel plate, poor alignment of the PCB), which causes the solder paste to be printed outside the pad. This is usually seen in the production of fine QFP;

The size and thickness of the PCB window are not designed correctly, and the tin lead alloy coating in the PCB pad design is uneven, resulting in excessive solder paste.

Solution: Adjust the printer to improve the coating of PCB pads.

3. Installation problems

Excessive solder paste pressure and diffusion flow after solder paste compression are common causes in production. In addition, the placement accuracy is not enough, components will shift, IC pins will deform, etc., which is easy to cause bridging.

4. Preheating problem

The heating speed of the SMT reflow oven is too fast, and there is no time for the solder paste solvent to evaporate

點擊

然后

聯系

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱