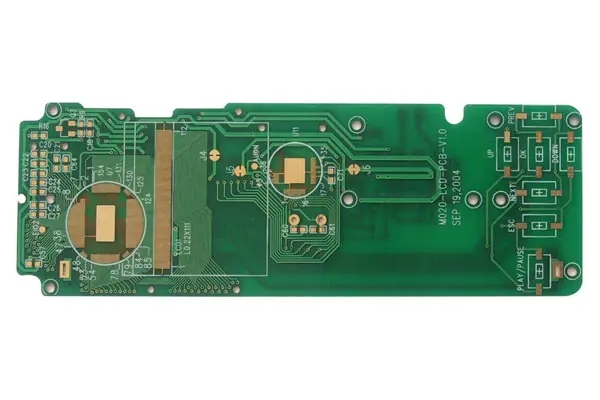

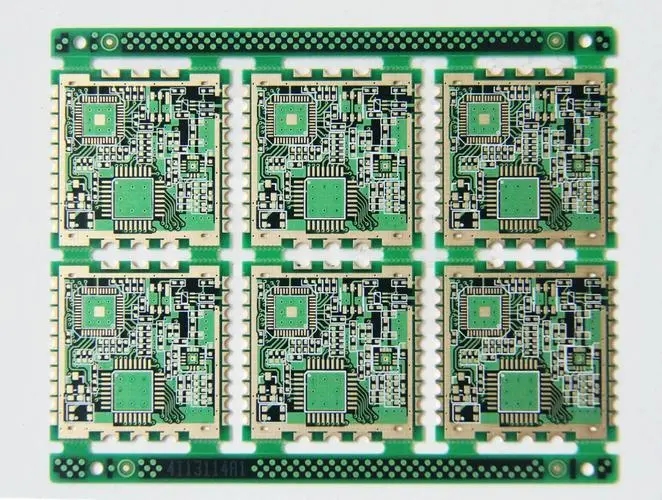

Flexible circuit board (FPC) is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film. FPC is also known as Flexible circuit board, whICh is favored for its light weight, thin thickness, free bending and folding and other excellent characteristics.

FPC is a technology developed in the 1970s for the development of space rocket technology in the United States. By embedding circuit design on flexible thin plastic sheets, a large number of precision components are embedded in narrow and limited spaces to form flexible circuits. This kind of circuit can be bent at will, folded, light in weight, SMAll in size, good in heat dissipation and convenient in installation, breaking through the traditional interconnection technology. In the structure of flexible circuit, the materials include insulating film, conductor and adhesive.

Constituent materials

1. Insulating film

The insulating film forms the base layer of the circuit, and the adhesive bonds the copper foil to the insulating layer. In multilayer PCB design, it is bonded with the inner layer. They are also used as protective coverings to isolate the circuit from dust and moisture, and to reduce stress during flexure. Copper foil forms a conductive layer.

In some flexible circuits, rigid components made of aluminum or stainless steel are used, which can provide dimensional stability, physical support for the placement of components and wires, and stress release. The adhesive bonds the rigid member to the flexible circuit. In addition, another material is sometiMES used in flexible circuits. It is a bonding layer, which is formed by coating adhesive on both sides of the insulating film. The adhesive layer sheet provides environmental protection and electronic insulation functions, and can eliminate a layer of film, and has the ability to bond multiple layers with fewer layers.

2. Conductor

Copper foil is suitable for use in flexible circuits. It can be electrodeposited (ED) or plated. One side of the copper foil prepared by electrodeposition is glossy, while the other side is dull and lusterless. It is a flexible material and can be made into many thicknesses and widths. The matt side of ED copper foil is often treated specially to improve its adhesion. In addition to flexibility, forged copper foil also has the characteristics of hard and smooth. It is suitable for applications requiring dynamic flexibility.

Flexible circuit board

3. Adhesive

In addition to bonding the insulating film to the conductive material, the adhesive can also be used as a covering layer, a protective coating, and a covering coating. The main difference between the two is the application mode used. The covering layer is bonded to cover the insulating film to form a circuit with a laminated structure. Screen printing technology used for covering and coating adhesive.

Not all laminated structures contain adhesives, and layers without adhesives form thinner circuits and greater flexibility. It has better thermal conductivity compared with the adhesive based laminated structure. Due to the thin structure of the adhesive free flexible circuit and the elimination of the thermal resistance of the adhesive, the thermal conductivity is improved. It can be used in the working environment where the flexible circuit based on the adhesive laminated structure cannot be used.

Basic structure

how

1. Operating Steps

(1) Before welding, apply flux on the PCB pad and treat it with a soldering iron once to avoid poor tin plating or oxidation of the pad, which may lead to poor soldering. Generally, the chip does not need to be treated.

(2) Use tweezers to carefully place PQFP chip on PCB board, and be careful not to damage pins. Align it with the bonding pad, and ensure that the chip is placed in the correct direction. Adjust the temperature of the soldering iron to more than 300 ℃, DIP a small amount of solder on the tip of the soldering iron, press the chip in the aligned position down with a tool, add a small amount of flux on the pins at the two diagonal positions, still press the chip down, solder the pins at the two diagonal positions, so that the core is fixed but cannot be moved. Recheck the alignment of the chip after welding the diagonals. If necessary, it can be adjusted or removed and re aligned on the PCB.

(3) When welding all pins, solder should be added to the tip of the soldering iron, and all pins should be coated with flux to keep the pins wet. Contact the end of each pin of the chip with a soldering iron tip until you see solder flowing into the pin. During welding, keep the tip of the soldering iron parallel to the pin to be welded to prevent overlapping due to excessive soldering tin.

(4) After soldering all pins, wet all pins with flux to clean solder. Remove excess solder where needed to eliminate any shorts and laps. Finally, use tweezers to check whether there is faulty soldering. After the inspection, remove the flux from the circuit board and carefully wipe the hard brush along the pin direction with alcohol until the flux disappears.

(5) Chip resistance capacitance components are relatively easy to solder. First, tin a solder joint, and then place one end of the component. Clamp the component with tweezers. After welding one end, check whether it is correctly placed; If it is aligned, weld the other end.

2. Precautions

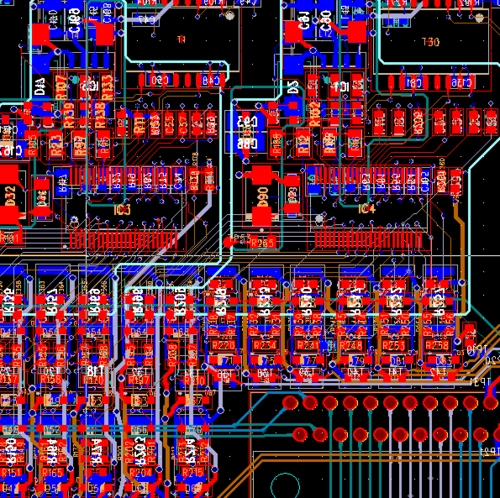

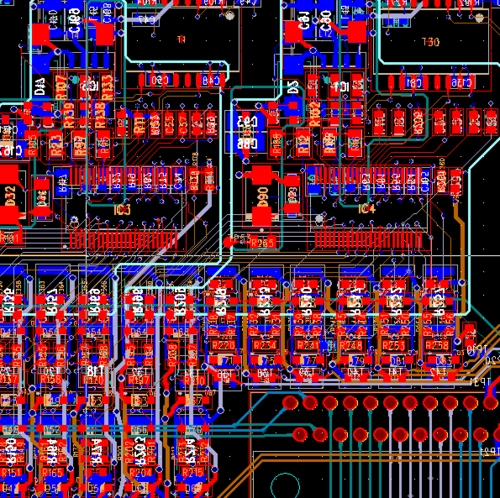

In PCB layout, when the size of the circuit board is too large, although the welding is easier to control, the printed PCB has long lines, increased impedance, reduced noise resistance, and increased cost; If it is too small, the heat dissipation will drop, the welding is not easy to control, and the adjacent lines will easily interfere with each other, such as the electromagnetic interference of the circuit board.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱