PCB layout of photovoltaIC power supply for microcontroller circuit

PCB layout of photovoltaic power supply

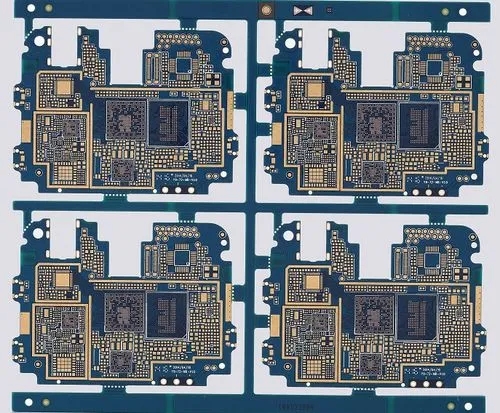

The following figure shows the layout of the top and bottom of the PCB. All components and most traces and copper pouring are on the top; The bottom is mainly ground level.

The microcontroller is the EFM8 Sleep Bee of Silicon Labs. The (relatively) large connector on the left provides a direct connection with the SiLabs USB debugging adapter. This connector consuMES considerable PCB space, making the overall design look larger than the actual.

The following figure shows the dimensions of the PCB in inches. The shorter horizontal dimension is that I try to estimate how SMAll the board can be if the debug connector is removed (and other components are rearranged).

So my guess is that the double deck of all components on one side may be less than 1.5 square inches. I would say this is very good, especially considering that we are talking about double-layer PCB.

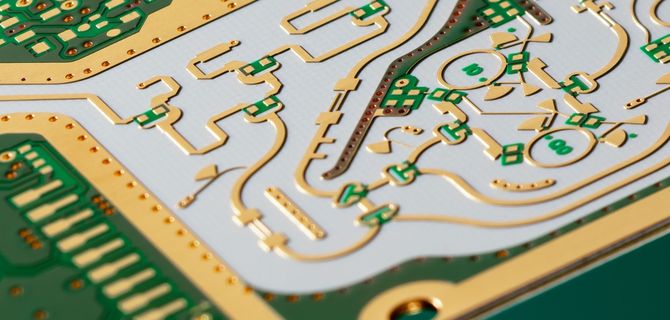

In addition, I don't think I will lose any performance by using two layers instead of four, because the bottom is almost a solid ground plane, and the top has enough space for wide power lines and wide ground connections (also because the microcontroller will operate at very low frequencies).

Small, but it may be smaller

Here are some other ways to reduce the size of the board:

·I chose larger passive components (0805 and 1206) because they are easier to assemble. If you plan to assemble circuit boards professionally, you can consider using 0603 or even 0402 (you may find an acceptable 2.2 in the 0402 package μ F capacitance, but for 0.1 μ F Capacitance and resistance, you can absolutely use 0402).

·I chose a larger package for the microcontroller; This is a 9mm × 9 mm QFP32. 32 pin non pin package size is significantly smaller (5 mm × 5 mm), and a 24 pin non pin package, which is smaller (4 mm × 4 mm)。 In my opinion, most applications built around this power supply do not need more than a few I/O pins, so a 24 pin package may be the best choice. I use a 32 pin device because the microcontroller does not have any other lead (i.e., non lead) packaging.

·I have provided high-precision 32.768 kHz crystal oscillator for real-time clock application; It is about the size of 0805 components. The microcontroller has an internal low-power oscillator with very low accuracy (± 10%), so if you do not need accurate timing, you can omit the crystal.

·There are currently four 2.2 charge pump switching regulators μ F Output capacitor, but only one is required.

·LED and its attached resistor are only used for debugging; They can be omitted in the final design.

·You may think that all circuits (switches, LDOs and two capacitors) related to the commissioning power supply can be eliminated. I do not recommend this because solar power is not a convenient power source for firmware development and testing.

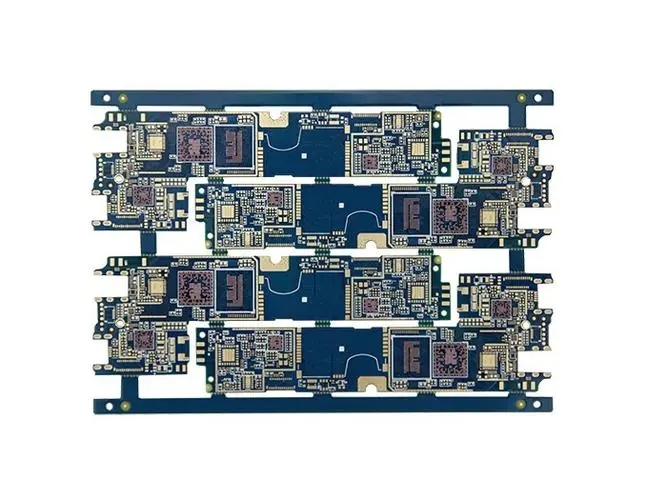

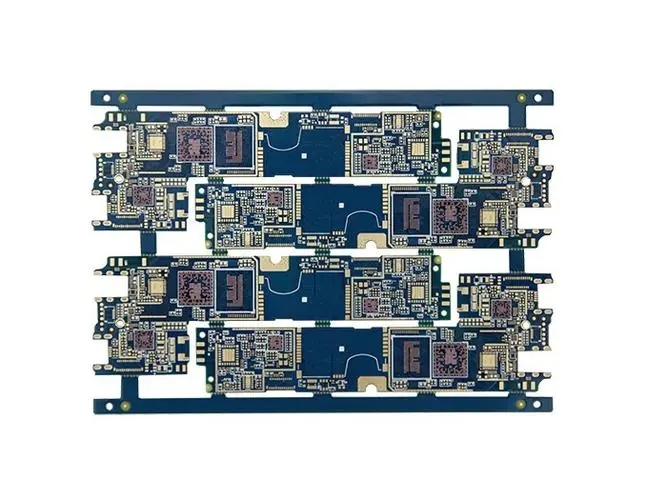

2-sided selection

The last item of how to make a smaller list is that there are components at the top and bottom of the board. When I wrote this article, I began to doubt whether the entire circuit is suitable for the area corresponding to the size of the solar cell, so that you can design a circuit board with only the top solar cell and other things at the bottom. I decided to delete some unnecessary components from the schematic diagram and try this idea. This is what I found (the dimensions are in inches):

This is a rough approximation, but as you can see, we are very close to the goal of plugging all circuits into the PCB space occupied by solar cells.

To create this component placement, I eliminated the resistance of three of the four output capacitors, the crystal, the LED, and the LED. I also switched the microcontroller package to QFN24. The passive components are still 1206 and 0805, but these larger packages can make up for the way you need to connect the microcontroller to the debug adapter. Of course, there is not much routing space, but if you can use four layers of panels (and there is enough space on the top below the solar cell), I think this is not a serious obstacle.

conclusion

We have discussed the PCB layout of the solar microcontroller board that I recently designed, and we have also studied a more spatial optimization implementation example, where the size of the PCB is close to the size of the solar cell.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the PCB layout of photovoltaic power supply for microcontroller circuits.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱