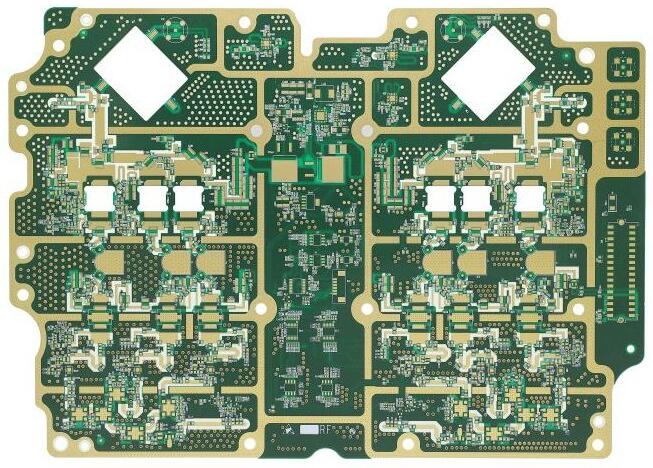

Gold and tin plating process of PCBA plate

PCBA plate making is very important, as is the process of gold and tin plating Let's discuss the various processes below

Advantages and disadvantages of various methods of PCB coating: First, we must understand why nICkel, silver, tin, chromium, zinc and gold plating are necessary Usually we use tin plating and gold plating

Common points: plating has common advantages, it can prevent corrosion (improve oxidation resistance) and play a decorative role.

The differences are as follows:

1. Galvanizing: The main purpose is to prevent corrosion. The utility model is characterized by low cost, convenient processing and good effect. The disadvantage is that it is not applicable to friction parts, which will affect the welding efficiency of PCB, and the number of users is usually SMAll.

2. Nickel plating: After nickel plating, it has good chEMIcal stability in the atmOSPhere and alkaline solution, and is not easy to change color. It can be oxidized at 600 ℃. It has high hardness and is easy to polish. The disadvantage is porosity.

3. Tin plating: high chemical stability, almost insoluble in dilute solution of sulfuric acid, nitric acid and hydrochloric acid, good solderability.

4. Chromium plating: divided into decorative chromium and hard chromium. Decorative chrome is mainly used for beauty and anti-corrosion, and its disadvantage is that it is not wear-resistant. Hard chromium mainly improves the hardness, corrosion resistance and hardness of the workpiece.

5. Gold and silver plating: mainly used for decoration and anti-corrosion. The disadvantage is that it is expensive.

Why use gold plated PCB?

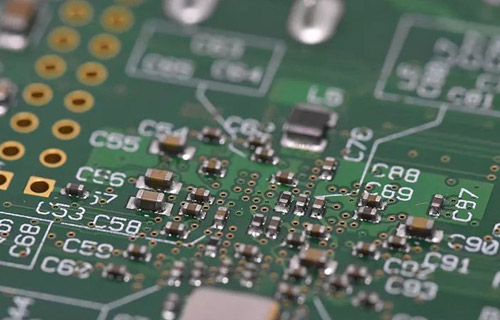

A. With the improvement of integrated circuit integration, the density of integrated circuit pins is increasing. The vertical PCB tin plating process is difficult to flatten the thin pads, which makes it difficult to place SMT;

B. In addition, the shelf life of sprayed tinplate is very short The gold-plated board just solves these problems: for the surface PCB installation process, it is particularly suitable for 0603 and 0402 ultra small surface installation, because the flatness of the pad is directly related to the quality of the solder paste printing process, which is important for the quality of subsequent reflow soldering As a result, full plate gold plating is common in high-density and subminiature surface mount processes

C. In the trial production stage, due to factors such as component procurement, the circuit board is usually not welded immediately, but it is usually used for weeks or even months. The shelf life of gold plate is better than that of lead. The length of tin alloy is several tiMES that of lead tin alloy plate, and the cost of gold plated PCB at the sample stage is almost the same as that of lead tin alloy plate.

Circuit board

3. Why do you need to spend a lot of money?

3. Why do you need to spend a lot of money?

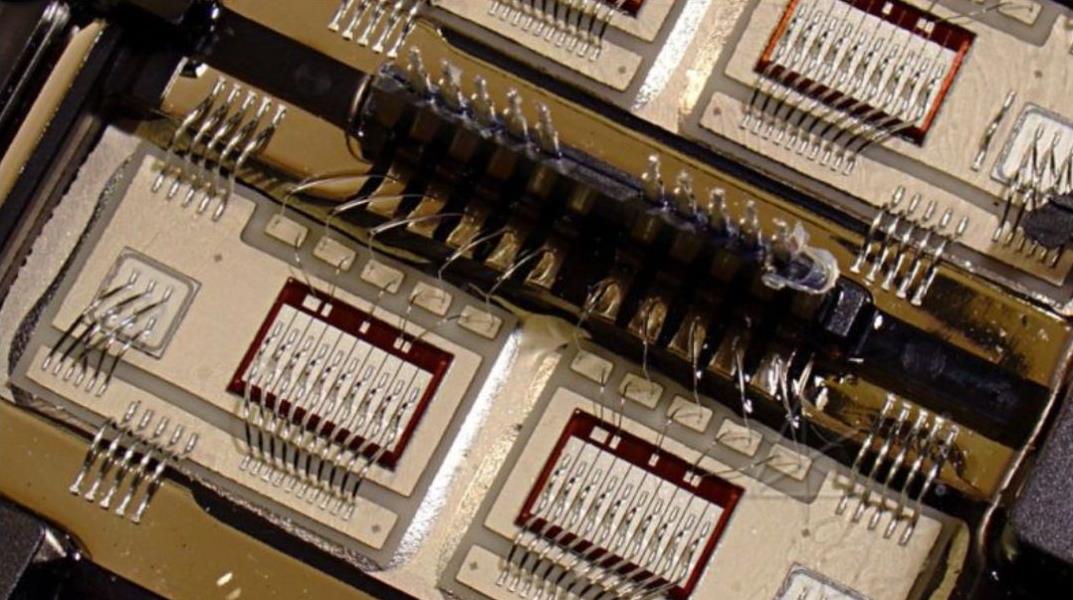

There are two gold plating processes (gold here is usually not pure gold, but nickel gold), one is electroplated gold, and the other is immersion gold (chemical method). The influence of tin on the gold plating process is greatly reduced., The effect of gold DIPping and tin plating is better; Unless the manufacturer requires bonding, most manufacturers will now choose Immersion Gold Technology!

1. Due to the different crystal structures formed by gold immersion and gold plating, gold immersion is yellower than gold plating, and customers will be more satisfied.

2. Due to the different crystal structures formed by gold immersion and gold plating, gold immersion is easier to weld than gold plating and will not cause poor welding and customer complaints.

3. Since there is only nickel and gold on the pad immersed in the gold plate, the signal transmission in the skin effect will not affect the signal on the copper layer.

4. Because the crystal structure of immersion gold is denser than that of gold plating, it is not easy to produce oxidation.

5. Since there is only nickel and gold on the bonding pad of the immersion gold plate, gold wire will not be generated and a slight short circuit will be caused.

6. Since the gilded board has only nickel and gold on the PCB pad, the bonding between the solder mask and the copper layer on this circuit is more firm.

7. The distance will not be affected during the compensation period of this project.

8. Because the crystal structure formed by PCB gold immersion and PCB gold plating is different, the stress of immersion type gold plating plate is easier to control, which is more conducive to bonding and processing for PCB products At the same time, this is precisely because immersion gilding is softer than gold plating. In retrospect, immersion gilding plates are not as wear-resistant as gold fingers

9. The flatness and standby life of PCB gilded board are equivalent to that of gilded board

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.

然后

聯(lián)系

電話(huà)熱線

13410863085Q Q

微信

- 郵箱