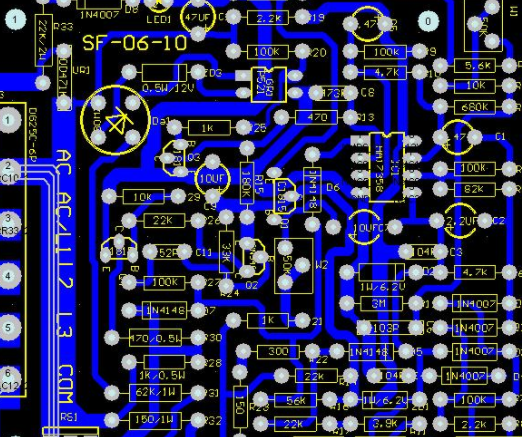

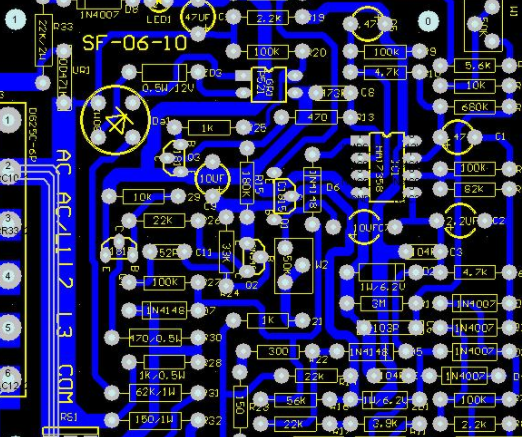

Explain the process of PCB plug hole

The through hole plays the role of connecting and conducting lines. The development of the electronIC industry also promotes the development of PCB, and also puts forward higher requirements for process and surface mounting technology. Plug hole technology CAMe into being. Now, let the engineer explain the PCB plug hole process for you in detail:

Plug hole process of PCB

1、 Plug hole process after hot air leveling

Non plug hole process shall be adopted for production. After hot air leveling, aluminum sheet screen or ink screen shall be used to complete the through hole plug holes of all fortresses. The process flow is: plate surface resistance welding → hot air leveling → plug hole → curing.

This process can ensure that the through hole will not lose oil after hot air leveling, but it is easy to cause the ink of the plug hole to pollute the board surface and be uneven.

2、 Plug hole process before hot air leveling

1. Use aluminum sheet to plug holes, solidify and grind plates for pattern transfer

This technological process uses a numerical control drilling machine to drill the aluminum sheet that needs to be plugged, make it into a screen, and plug the hole. The process flow is: pretreatment → plug hole → grinding plate → pattern transfer → etching → resistance welding of plate surface.

This method can ensure that the through hole plug hole is flat, and the hot air leveling will not have quality problems such as oil explosion and oil loss at the hole edge. However, this process requires one-time copper thickening, which requires high copper plating on the whole plate.

2. Plug the hole with aluminum sheet and then directly screen the plate surface for resistance welding

In this process, a numerical control drilling machine is used to drill the aluminum sheet that needs to be plugged into a screen plate, which is instalLED on a screen printing machine for plugging. The machine is parked for no more than 30 minutes, and 36T screen is used to directly solder the screen plate surface. The process flow is: pre-treatment - plug hole - silk screen - pre drying - exposure - development - curing

This process can ensure that the through hole cover is well oiled and the plug hole is flat. After hot air leveling, the through hole is free of tin, and there is no tin bead in the hole. However, it is easy to cause solder pad on the ink in the hole after curing, poor solderability, etc.

3. Aluminum sheet plug hole, development, pre curing, plate surface resistance welding after plate grinding

The numerical control drilling machine shall be used to drill the aluminum sheet required to be plugged into a screen plate, which shall be installed on the displacement screen printing machine to plug the hole. The plug hole must be full, and then it shall be cured, and the plate shall be ground for surface treatment. The process flow is: pretreatment - plug hole - pre drying - development - pre curing - plate surface resistance welding

This process can ensure no oil loss and oil explosion in the vias after hot air leveling, but it is difficult to completely solve the problem of tin bead in the vias and tin coating in the through holes.

4. Resistance welding of plate surface and plug hole shall be completed at the same time

This method uses 36T (43T) screen, which is installed on the screen printing machine, and uses a backing plate or a nail bed. When the plate surface is completed, all the through holes are plugged. The process flow is: pretreatment - silk screen - pre drying - exposure - development - curing.

The process time is short and the utilization rate of equipment is high. It can ensure that no oil will fall from the via and no tin will be added to the through hole after hot air leveling. However, due to the use of silk screen to plug the hole, there is a lot of air in the through hole, resulting in holes, unevenness, and a SMAll amount of tin in the through hole.

The above is the explanation given by the editor of pcb circuit board company. If you want to know more about PCBA, you can go to our company's home page to learn about it. In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱