Manufacturing method of SMT template and correct selection of solder paste

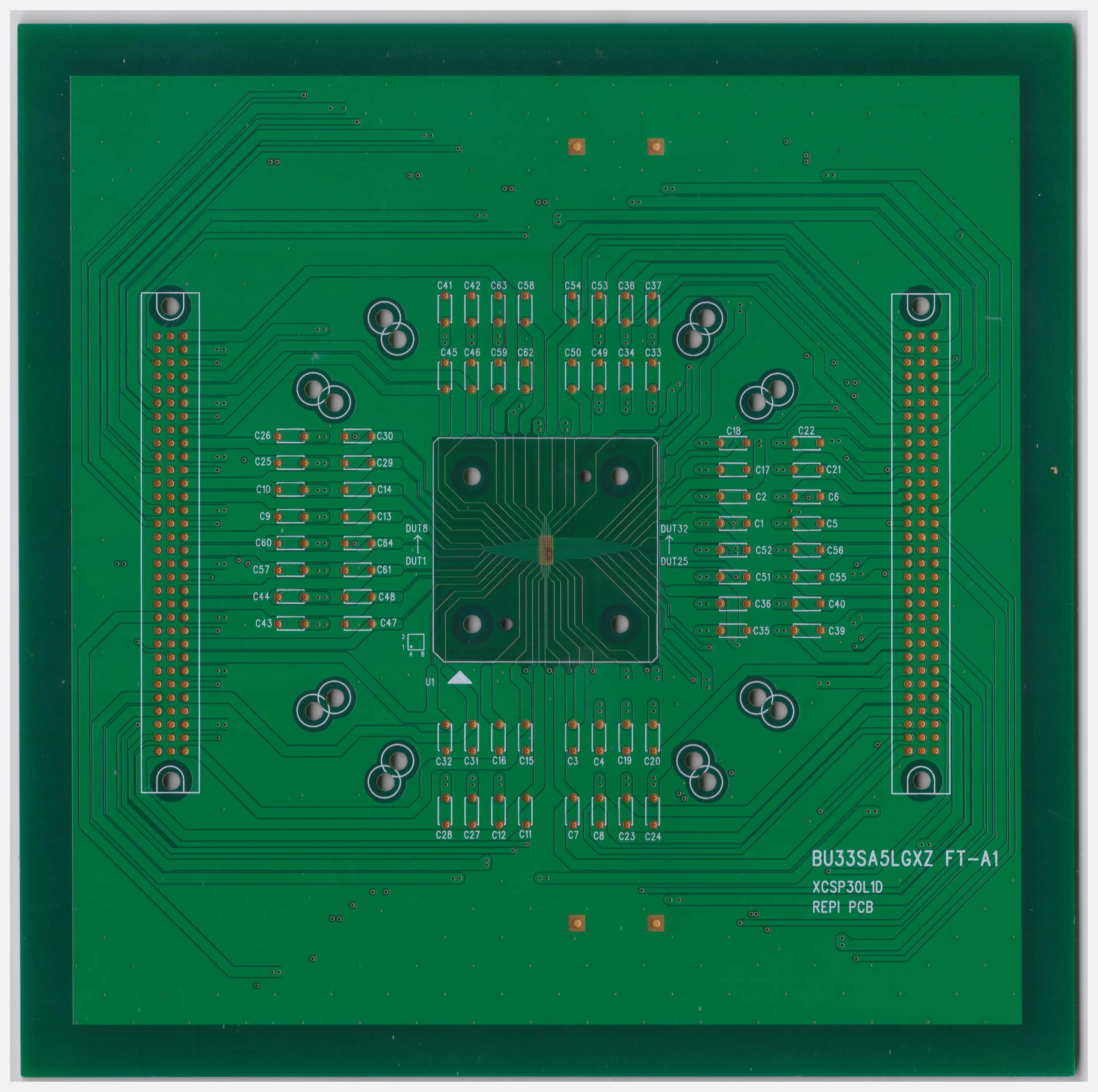

With the development of SMT and the continuous improvement of the requirements for stencils, templates are generated. Templates are used to quantify and distribute solder paste, whICh is the key factor to ensure the quality of solder paste printing.

At present, metal templates are mainly used, and there are three manufacturing processes: chEMIcal etching, laser cutting and electroforming.

(1) Chemical corrosion method: The chemical corrosion method is the earliest method used to manufacture templates, which is commonly used in the production of tin phOSPhorus bronze or stainless steel templates. Its technological process mainly includes exposure, development, etching, steel sheet cleaning, MESh, etc. The advantages are one-time molding, fast speed and low price; The disadvantages are that it is easy to form an hourglass shape (insufficient etching) or the opening size becomes larger (excessive etching), there are many production links, and the cumulative error is large. The production process is polluted, which is not conducive to environmental protection.

(2) Laser cutting method: laser cutting method uses a laser generator to directly cut windows on metal templates like a photo plotter. It is commonly used for the production of stainless steel and polymer polyester templates. Its technological process mainly includes coordinate taking, data processing, laser cutting, polishing, mesh tensioning, etc. This method has the advantages of high dimensional accuracy, good window shape, SIMple process, short cycle, and smooth hole wall; The disadvantage is that cutting one by one is slow.

(3) Electroforming method: electroforming method is a technology that uses addition method to make templates. Generally, nickel is used as template material. It is made by electrodepositing metal on the mold through electroforming, and is commonly used for making nickel material templates. Its technological process mainly includes coating of photosensitive film, exposure, development, electroforming nickel, forming, steel sheet cleaning, mesh, etc. The utility model has the advantages that the hole wall is smooth, and is particularly suitable for the production of ultra-fine spacing templates; The disadvantages are that the process is difficult to control, the production process is polluted, which is not conducive to environmental protection, and the production cycle is long and the price is too high.

Teach you how to choose solder paste correctly

In the SMT process, it is very important to select the appropriate solder paste. There are many types and specifications of solder paste. Even the same manufacturer has differences in alloy composition, viscosity, particle size, and price. However, as long as the following points are kept in mind, the selection of solder paste becomes very simple.

1. Select the appropriate alloy composition. Alloy is the material to form solder joints, and the alloy composition also determines the welding temperature, so it is important to determine the reasonable alloy composition. The alloy composition is mainly selected according to electronic products and processes. The alloy composition compatible with the welding end of components shall be selected as far as possible, and factors such as welding temperature shall be considered.

2. Select the appropriate solder paste viscosity. Because there are many ways to print solder pastes, and different ways have different requirements for the viscosity of solder pastes, when selecting solder pastes, we should compare a variety of solder pastes and evaluate their demoulding, thixotropy, viscosity, solder joint defects, etc. to select the appropriate solder pastes.

3. Select the appropriate flux. The printability and solderability of solder paste mainly depend on the flux in the solder paste, so it is very important to select a suitable flux. When selecting a flux, its activity should be selected according to the storage time and surface oxidation degree of PCB and components. The non active (R) type is selected for high reliability products, the moderately active (RMA) type is used for general products, the storage time of components is long, and the active (RA) type is used when the surface is severely oxidized.

4. Determine the proportion of alloy composition and flux in solder paste. The proportion of alloy composition and flux directly affects the printability and viscosity of solder paste, and the proportion of flux is generally 10% - 15%.

In fact, the selection of solder paste is very simple. As long as we compare and select the alloy composition, viscosity, flux and its ratio, we can determine the appropriate solder paste. By comparison and selection, we can determine the appropriate solder paste.

PCB manufacturing, PCB design and PCBA processing manufacturers will explain the manufacturing method of SMT template and correct selection of solder paste

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱