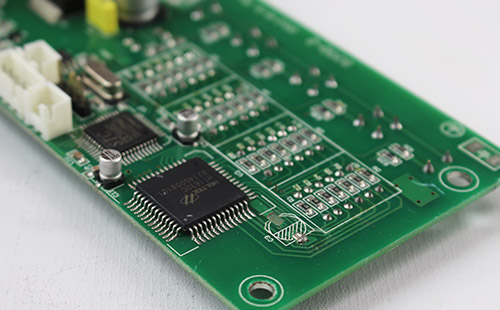

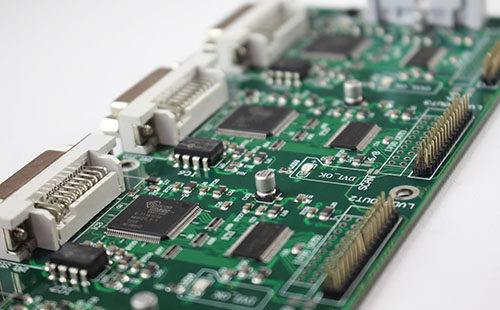

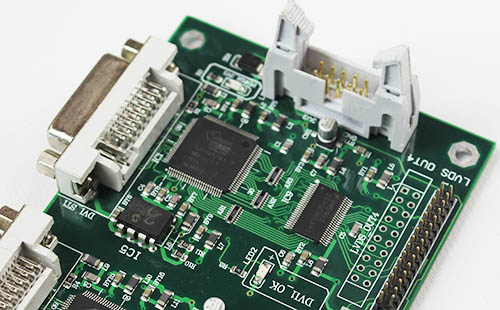

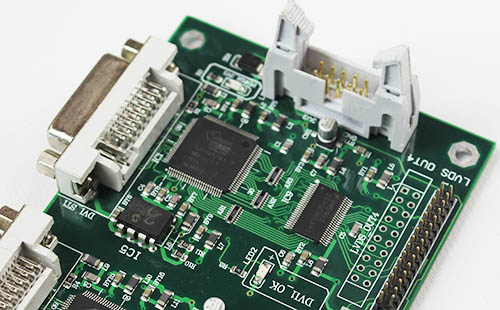

DetaiLED process flow of HDI buried blind hole circuit board

1、 Overview: blind hole and buried hole boards are mainly used for making high-density and SMAll mICroporous boards, aiming to save circuit space and reduce PCB volume, such as mobile phone boards,

2、 Classification: I). Laser drilling,

1. Reasons for laser drilling: a. Customer data requires laser drilling; B Because the blind hole aperture is very small<=6MIL, it can only be drilled with laser C. Special blind holes, such as L1 to L2 with blind holes and L2 to L3 with buried holes, must be drilled with laser

2. Principle of laser drilling: laser drilling is to use the plate to absorb laser heat to vaporize or dissolve the plate into a hole, so the plate must have light absorption, so general RCC materials, because there is no glass fiber cloth in RCC, will not reflect light

3. RCC material introduction: RCC material is resin coated copper foil: it is formed by coating a layer of resin with unique performance on the rough surface of electrolytic copper foil. Three commonly used suppliers: Shengyi, Mitsui, LG. Materials: resin thickness 50, 65, 70, 75, 80 (um), copper foil thickness 12, 18 (um) and other RCC materials have high TG and low TG, and the dielectric constant is smaller than the normal FR4. For example, the dielectric constant of Guangdong Shengyi's S6018 is 3.8, So pay attention when there is impedance control Other specific reference materials can be referred to PE and RD departments

4. Requirements for making laser drilling tools: A) It is difficult for the laser to burn through the copper sheet, so before laser drilling, it is necessary to etch out Cu Clearance (B) of the same size as the completed aperture at the blind hole The positioning MARK of laser drilling shall be added to L2/LN-1 layer, which shall be indicated on the modification page of MI film. C) The film for blind hole etching must be made with LDI, and the size of LDI plate shall be used for blanking.

5. Features of production process: A) When the total number of layers of the line is N, the L2-Ln-1 layer shall be fabricated according to the normal board process, B) After pressing the plate, the process is changed to: --->drilling LDI locating holes --->dry film --->etching blind holes --->laser drilling --->drilling through holes --->copper sinking --- (normal process).

6. Other precautions: A). Since all RCC materials have not passed UL certification, this type of plate will not be marked with UL temporarily B). As for the layout structure on the MI, in order to avoid using this kind of RCC containing material layout as a pseudo laminate (because the film room is different from the normal one), we should pay attention to the separation of RCC material and L2 or Ln-1 layer when drawing the layout structure, such as SR2711/01: C). IPC-6016 is the HDI plate standard: laser blind hole wall copper thickness: 0.4mil (min) Solder ring requirements: Tangency is allowed. If the PAD size is less than 5mil larger than the aperture, it is recommended to add TEARDROP D). Plate edge>=0.8 "

2) . Mechanical drilling blind/buried hole:

1. Scope of application: mechanical drilling can be considered when the drill bit size is>=0.20mm;

2. Electroplating method for blind hole (refer to RD bulletin TSFMRD-113): A) Normally, the copper surface of any layer of circuit can only be plated for one time+one time for pattern plating; B). Under normal circumstances, after the full pressing plate process is completed, the plate thickness is>=80MIL, and the through hole needs plate electroplating+pattern electroplating. Therefore, the outer plate surface cannot be plated when the blind hole is plated C). After the above two conditions are met, the electroplating of blind holes shall be carried out as follows: I) When the width of the outer line is greater than 6 MIL and the thickness of the through-hole plate is less than 80 MIL, the outer plate surface can be completely plated in blind hole electroplating II) When the line width of the outer layer is greater than 6 MIL, but the thickness of the through hole plate is greater than 80 MIL, the outer layer plate surface shall be coated to protect the plate surface during blind hole electroplating; III). When the line width of the outer layer is less than 6 MIL and the thickness of the through-hole plate is>=80 6MIL, the outer layer plate surface shall be coated to protect the plate surface during blind hole electroplating;

3. Film pasting method: 1) When the aspect ratio of the blind hole is less than 0.8 (L/D), the outer layer is exposed by pasting a dry film and the inner layer is electroplated; 2) When the aspect ratio of the blind hole is greater than 0.8 (L/D), the outer layer is exposed by pasting a dry film and the blind hole. Electroplated exposure film or LDI is required for exposure and the inner layer is electroplated

4. Blind hole exposure method: 1) When the blind hole is<=0.4MM (16MIL), use LDI to expose the blind hole; 2) When the blind hole is>0.4MM (16MIL), use film to expose the blind hole,

5. Method of pasting film for buried hole: 1) When the line width of the buried hole surface is<=4MIL, the buried hole plate surface needs to be coated with exposed points; 2) When the line width of the buried hole surface is>4MIL, the buried hole plate surface is directly plated,

6. Precautions: 1) L/D in aspect ratio: L=medium thickness+copper thickness, D=blind hole/buried hole diameter. 2) Blind hole/buried hole electroplating film: * diameter of exposure point D=D-6 (MIL)

III Some special requirements for blind orifice plate:

1. Resin plug blind hole: when the size of the embedded hole is large and the number of holes is large, when pressing plate, it requires a lot of resin to fill the embedded hole. In order to prevent it from affecting the thickness of the pressing plate, if required by R&D, the embedded hole can be pre plugged with resin in front of the pressing plate, and the hole plugging method should refer to the green oil plug hole

2. When there are blind holes in the outer layer, a. there will be glue flowing out of the outer layer when pressing plate, so a glue removal process is required after pressing plate; B. Because the surface of the outer layer will be cleaned before the dry film, there is a plate grinding process, and the chEMIcal copper deposition is very thin, only 0.05MIL to 0.1MI, so it is easy to wear off during plate grinding, so we will add a plate electroplating process to thicken the copper The relevant processes are as follows: pressing plate - glue removal - drilling - copper deposition - plate electroplating - dry film - pattern electroplating

3. In addition, PIN-LAM pressing plate may be used when making blind hole plates with high layers, but it should be noted that only when the thickness of CORE is less than 30 MIL, our machine can punch PIN-LAM holes, such as PR4,726,010, we use ordinary pressing plate 5. When writing the LOT card, for the sub process, the layout structure of a single sub process should be written, and the layout structure of the main process should also be written in the special requirements to facilitate the next process.

PCB manufacturers, PCB designers and PCBA processors will explain the process flow of HDI buried blind hole PCB.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱