DetaiLED manufacturability analysis of circuit board manufacturers

Manufacturability analysis, that is, manufacturability review technology, refers to that the designer, with the help of a group of tools and relevant knowledge base, evaluates the manufacturability of the product at the product design stage, and modifies the design on the prEMIse of ensuring the product function and quality, so that the product design meets the requirements of the manufacturing process and has good manufacturability. DFM is mainly used to analyze the development effICiency, cost and manufacturability of products manually.

Traditional manual review process

The traditional manual review not only delays the project progress of the model project, but also cannot consider the constraints of product manufacturability, cost and other aspects at the early stage of design.

Main features of manufacturability analysis technology

DFM technology has added three feedback loops in the electronic product development process, and is preceded by the manufacturing feedback in PCBA manufacturing and the quality feedback in the use of finished electronic products. The main features are as follows:

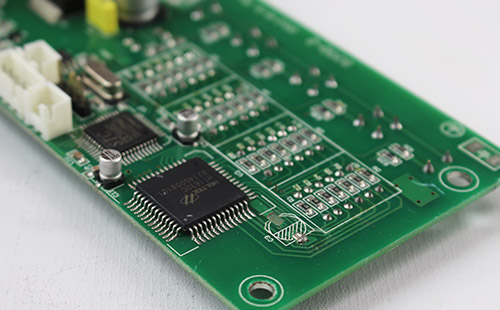

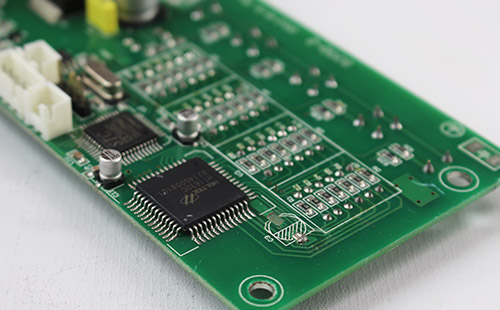

① With the synchronization of design and manufacturability, designers can use DFM to analyze the manufacturability of their products and correct relevant defects when designing PCBA cabling. At the same time, it also reduces the limitations of designers due to lack of experience, improves the design efficiency and one-time success rate, and avoids version changes due to design errors in subsequent debugging.

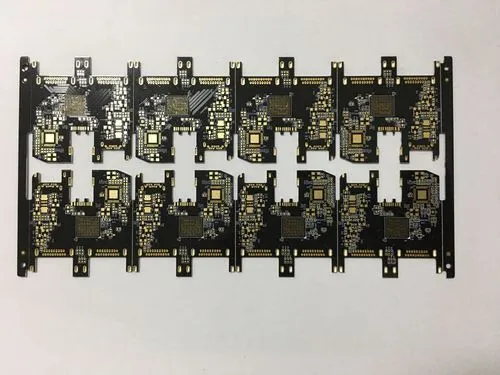

② With the synchronization of process and design, DFM has built a bridge between design and process, so that the process can be involved in the design in advance, and in combination with the current production situation, the specific problems that need to be improved in design can be effectively fed back to the designers to achieve high-quality process design of bare PCB.

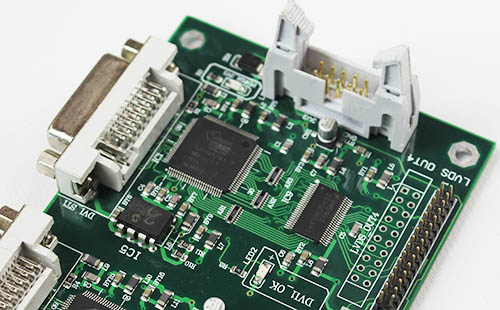

③ With the synchronization of materials, processes and design, DFM can check the compatibility between the effective BOM of materials and design documents, conduct SIMulation assembly for PCBA, complete the work that cannot be completed in the traditional process review, and provide the most accurate and effective data for the next stage of production and manufacturing.

The application of DFM technology in the development process of electronic products can change the traditional development mode, enable technologists to fully participate in the design stage of model products, and quickly and intelligently find possible problems in manufacturing through the rules of manufacturability analysis, so as to make predictive decisions, greatly improve the level of equipment research and development, achieve one-time manufacturing success, reduce costs, shorten product development cycle The purpose of improving equipment quality.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the manufacturability analysis and main features.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱