Multilayer Lamination Process of Automotive circuit board Multilayer

circuit board manufacturing, circuit board design, PCBA processing manufacturer will explain the multi-layer lamination process of automobile circuit board

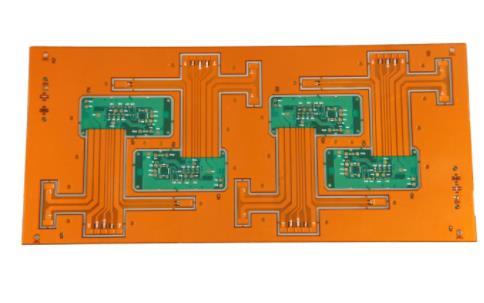

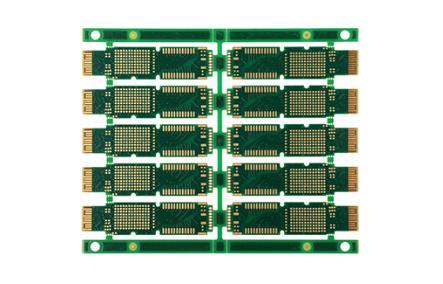

Multilayer lamination of automobile circuit board is a sequential process. This means that the basis of the delamination will be a copper foil with a layer of prepreg on it. The number of prepreg layers varies according to the operation requirements. In addition, the inner core is deposited on the prepreg blank layer, and then the inner core is further filLED with the prepreg blank layer covered with copper foil. In this way, a laminate of the multilayer automobile circuit board lamination is made. Stack the same laminates together. After adding the final foil, the final stack is created, called "book", and each stack is called "chapter".

After the book is finished, transfer it to the hydraulIC press. The hydraulic press is heated and a large amount of pressure and vacuum are applied to the books. This process is called curing because it inhibits contact between the laminates and blends the resin prepreg with the core and foil. Then take out the components and cool them at room temperature to allow the resin to settle, thus completing the manufacturing of copper multilayer automobile circuit board.

After cutting different raw material sheets according to the specified size, different number of sheets shall be selected according to the thickness of the sheet and stacked into slabs. The stacked slabs shall be assembled into pressing units according to the process requirements. Push the pressing unit into the laminator for pressing.

5 stages of temperature control

(a) Preheating stage: the temperature is from room temperature to the starting temperature of the surface curing reaction. At the same time, the core resin is heated, and some volatiles are discharged. The applied pressure is 1/3~1/2 of the total pressure.

(b) Thermal insulation stage: make the surface resin solidify at a lower reaction rate. The core layer resin is uniformly heated and melted, and the resin layer interfaces begin to fuse with each other.

(c) Temperature rise stage: the temperature rises from the curing start temperature to the maximum temperature specified during pressing, and the temperature rise speed should not be too fast, otherwise the curing speed of the surface layer will be too fast, and it can not be well integrated with the core resin, resulting in delamination or cracks of the finished product.

(d) Constant temperature stage: the stage when the temperature reaches the highest value and remains constant. The role of this stage is to ensure that the surface resin is fully solidified, the core resin is evenly plasticized, and the melting bonding between the layers of sheets is guaranteed. Under the pressure, it becoMES a uniform and dense whole, so as to achieve the best performance of the finished product.

(e) Cooling stage: when the surface layer resin in the slab has fully solidified and fully fused with the core layer resin, it can be cooled. The cooling method is to pass cooling water in the hot plate of the press, or natural cooling. This stage shall be carried out under the specified pressure and the proper cooling rate shall be controlled. When the plate temperature drops below the proper temperature, the pressure can be released.

Circuit board manufacturing, circuit board design and PCBA processing manufacturers will explain the multi-layer lamination process of automobile circuit board multilayer boards.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱