Why is it diffICult to put tin on 5G PCB? What is the solution?

PCB manufacturers, PCB designers and PCBA manufacturers explain to you why it is difficult to put tin on 5G PCB? What is the solution?

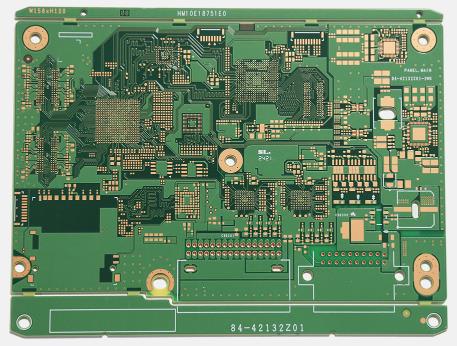

5G PCB shall be dust-free throughout the production process, especially during exposure, etching, subsequent tin spraying, gold deposition, testing and packaging, so as to prevent impurities from getting onto solder paste or bonding pad and affecting welding.

As for the gilt printed circuit board, special attention should be paid to the oxidation of the outside air and sweat stains. The gilt 5G printed circuit board is relatively easy to be oxidized. The manufacturer and customer of welding should try to ensure that the factory packaging of the printed Circuit board manufacturer is complete before the patch is ready. Do not easily remove the vacuum packaging, otherwise the patch will cause difficulties after the oxidation.

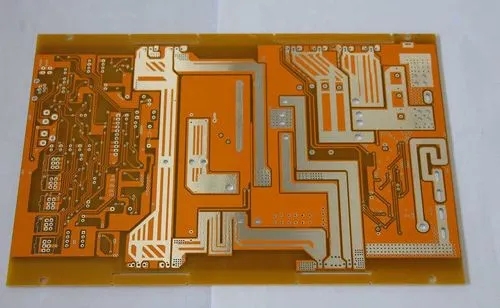

The tin coated 5G PCB should be kept clean and tidy, especially the tin surface should be kept flat. There will be water stains when tin is sprayed, which is caused by the unclean tin surface and should be reworked. The uneven tin surface should be caused by improper operation during tin spraying, and should be adjusted in time.

SMT chip manufacturers should pay attention to cleaning the tin surface as much as possible before welding. Precision pads should ensure that the tin is full during welding. If possible, flux should be added for welding. Generally, environmental protection products are required now, so lead-free tin is used in the factory. Lead free PCB will cause difficulties in welding. When welding, appropriate flux can be added to help PCB pads to saturate with tin.

A Brief Talk on the Function of 5G PCB brushing Electronic Three proof Paint?

Under real conditions, such as chEMIcal, vibration, high dust, salt fog, humidity and high temperature, PCB may have corrosion, softening, deformation, mildew and other problems, resulting in PCB circuit failure. The three proofing paint is applied to the surface of the circuit board to form a layer of three proofing protective film (the three proofing refers to moisture-proof, salt fog proof and mold proof).

It can protect the circuit from damage under conditions such as chemical substances (such as fuel, coolant, etc.), vibration, moisture, salt spray, humidity and high temperature. Under these conditions, the circuit board may be corroded, mildewed and short circuited, resulting in the failure of the circuit without the use of three proofing paint, thus improving the reliability of the circuit board, increasing its safety factor and ensuring its service life. In addition, since the three proofing paint can prevent electric leakage, higher power and closer PCB spacing are allowed. Thus, the purpose of miniaturization of components can be met. PCB manufacturers, PCB designers and PCBA manufacturers explain to you why it is difficult to put tin on 5G PCB? What is the solution?

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱