PCB fusion welding is a method that heats the interface of the workpiece to the molten state in the welding process and completes the welding without pressure. In the welding process, the heat source quICkly heats and melts the joint of the two PCB workpieces to be welded, forming a molten pool.

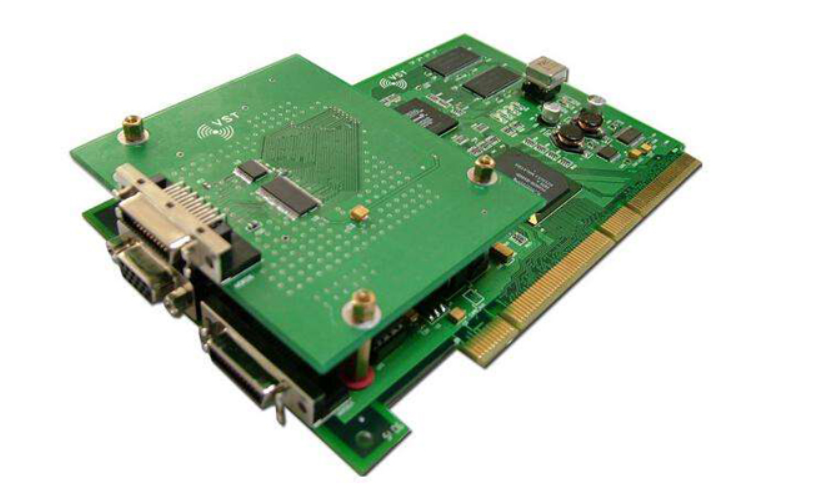

Common PCB in life

During welding, if the atmOSPhere is in direct contact with the high-temperature molten pool, the oxygen in the atmosphere will oxidize metals and various alloy elements. Nitrogen and water vapor in the atmosphere will enter the molten pool, and holes, slag inclusions, cracks and other defects will be formed in the weld during the subsequent cooling process, which will reduce the quality and performance of the weld.

What are the soldering tools for circuit boards? At present, the welding technology of electronIC components is mainly used. Soldering technology uses tin based tin alloy as solder, and the solder melts at a certain temperature, and the metal solder and tin atoms attract, diffuse and bond together to form a wet bonding layer. It appears that the copper platinum and component leads of the printed circuit board are very smooth. In fact, their surfaces have many tiny bumps. The molten tin solder diffuses along the solder surface through capillary suction, thus forming solder and solder. The penetration of parts, components and printed boards is firmly combined and has good conductivity.

The selective welding process includes: flux spraying, circuit board preheating, DIP welding and drag welding. Flux coating process plays an important role in selective welding. When PCB welding heating and welding are to be completed, the flux shall be very flexible to prevent bridging and circuit board oxidation. The manipulator sprays the flux to make the circuit board pass through the flux nozzle, and then sprays the flux to the welding position of the pcb circuit board.

The inspection methods of PCB welding quality include appearance inspection, infrared inspection and online test. Among these methods, the most economical and commonly used is the visual method, which is economical, convenient, SIMple and feasible. Several other methods require some kind of device support. DeSPIte huge investment, it can still ensure high inspection reliability.

Why do automation manufacturers use PCB proofing

In the system that describes the behavior of the control process, the data structure that stores the process management and control information is calLED PCB proofing, which is a part of the process object and the most important record data of the operating system. For process management and control, the most important data structure is that each process has a PCB proofing process, and the entire process is run when the process is generated, until the PCB is generated and the process is canceLED. Pcb proofing records all the information required by the operating system to describe that the current state of the process is the control process behavior of pcb proofing.

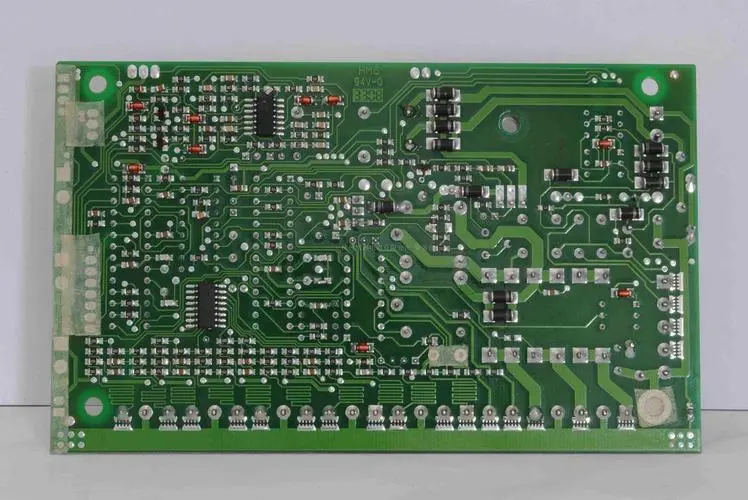

Products from pcb proofing

As a basic unit, pcb proofing can independently execute programs that cannot be executed independently in multiple program environments, including data. Pcb proofing is a process that can be executed simultaneously with other processes. This is a process based on pcb proofing, or a process that controls and manages concurrent operations. Pcb proofing is a static description of the process, which consists of three parts: PCB, associated program segments, and the data structure set in which the program segments are run. The function of pcb proofing is to create basic units that can independently execute programs that cannot be executed independently in multiple program environments, and create processes that can be executed simultaneously with other processes. Is to do. A program segment is a program code segment that can be executed by the CPU by the process scheduler of the process, while the PCB data segment of the process is the original data processed by the program corresponding to the process, or the intermediate or final value generated after the execution of the program, which may also be data that is inaccurate.

Throughout the life cycle of the process, the system always uses pcb proofing to control the process. That is to say, the pcb proofing is being processed because the system is based on the PCB of the process and knows that the process exists, rather than just displaying other things. This is undoubtedly a very good choice for our pcb proofing. The correctness in the process makes pcb proofing stable and accurate, which is why so many automation manufacturers choose pcb proofing.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱