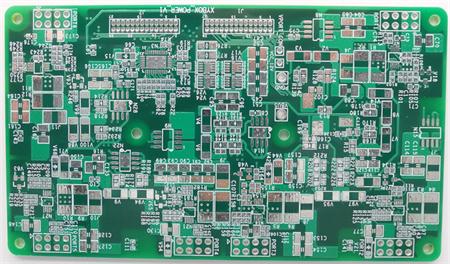

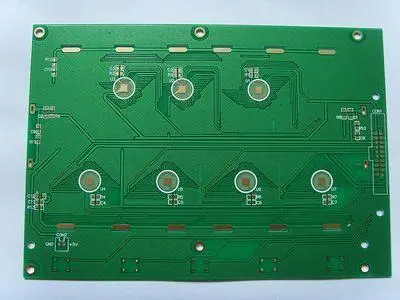

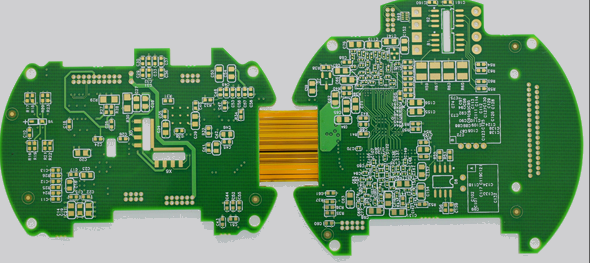

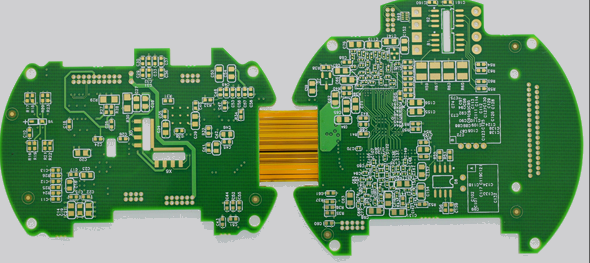

FPC soft plate flat plate impedance plate

Impedance plate production process flow:

1. Feeding:

2. The sheet type, sheet thICkness and copper foil thickness used must be produced according to MI requirements.

3. Impedance plate shall not be made by self pressing core plate or micro etching of copper surface. (The pressing thickness and copper thickness cannot be completely controlLED within the range)

4. Inner line:

5. Detect the film line width and line gap before alignment exposure, and check the film quality to avoid positioning problems.

6. During the alignment exposure, the first board QA must be done first to detect the impedance line width/line spacing within the range required by MI and open/short circuit problems with a hundred position mirror, and the batch production can only be carried out if it is qualified.

7. During exposure production, clean the film with a sticky roller once for every 1PNL plate produced; The quality of film shall be checked once for every 25PNL produced, and the exposed glass and Mylar shall be cleaned once with alcohol.

8. Try to avoid rework of impedance plate. (Do not use impedance plate as exposure ruler, other plates can be used for production)

9. When developing and placing boards, the side with impedance lines must face the lower board. For example, for boards with impedance lines on both sides, the side with more impedance lines or dense lines must face the lower board.

The impedance line width (impedance strip and impedance line inside the board) is required to be controlled at the upper middle limit.

For example, if the impedance line width is required to be 0.20mm and the tolerance is+/- 10%, the impedance line width is required to be controlled between 0.20mm and -0.22mm after etching. (Due to micro etching or rework during browning, the line width is affected to some extent)

When etching the release plate, the side with impedance line control shall face the lower plate. For example, for the plate with impedance lines on both sides, the side with more impedance lines or dense lines shall face the lower plate for production.

Impedance plates can only be mass produced after the first plate meets the requirements. If it is unqualified, the first plate shall be made again, and mass production can only be carried out after it is qualified.

In the process of mass production of impedance plate, the detection frequency must be tightened. Line width detection shall be conducted once every 30PNL produced. In case of any abnormality, relevant personnel shall be informed to follow up and improve.

AOI:

If there is an open circuit or gap in the impedance line, bonding line can be carried out, but strict detection must be carried out after bonding line to ensure that the impedance line width and binding force behind bonding line can meet the requirements.

If there is an open circuit or gap on the impedance strip, it must also be connected. In the subsequent impedance detection, the results of the impedance strip can also represent the impedance of the Production board.

Browning:

The first board must be confirmed as OK before mass production.

The impedance plate shall be reworked at most once. (Due to micro etching in the pretreatment and excessive rework, the line will be fine and the copper thickness of the line will be reduced, which will affect the impedance value)

Pressing:

Copper foil, PP sheet and laminated structure used must be produced according to MI requirements.

Pay attention to the control of pressing plate parameters to ensure the consistency of plate thickness as much as possible.

For the plates that have not been produced in the impedance plate pressing process, the 2-5PNL head plate shall be pressed first. After pressing, the long arm plate thickness measuring instrument shall be used to measure the full thickness and surface quality of the plates for QA, and the plates shall be sent to the physical room for microsection to analyze the thickness of each dielectric layer and copper thickness, and relevant data and reports shall be recorded.

After each batch of impedance plates has been pressed, QA shall inspect the thickness and surface quality of the plates at a ratio of 30% to confirm whether the thickness meets the MI requirements, and conduct phase detection

The above is the FPC soft plate, flat plate and impedance plate,

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱