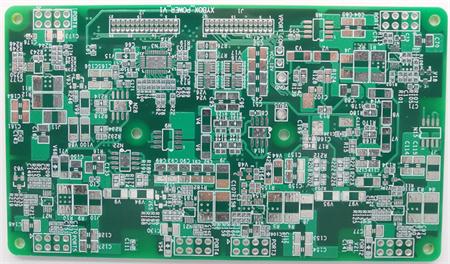

PCB board maintenance, also known as chip maintenance technology, is a professional technology to complete circuit detection, component detection, fault diagnosis and maintenance of PCB boards without drawings. In a broad sense, PCB board maintenance is applICable to any equipment board card. At present, affected by technology, cost, MARKet demand and other factors, PCB board maintenance mainly refers to chip level maintenance of advanced products, including touch screen maintenance, instrument maintenance, server maintenance, industrial computer maintenance, CMM maintenance, injection molding machine PCB board maintenance, embroidery machine PCB board maintenance, CPU board maintenance, industrial control products, etc. Among them, the paperless PCB board maintenance technology advocated by Shenzhen Yuanfa Industrial Control Maintenance Co., Ltd. is currently recognized as a more scientific technical indicator in the pcb industry.

essential information

PCB board maintenance, also known as chip maintenance technology, is a professional technology to complete circuit detection, component detection, fault diagnosis and maintenance of PCB boards without drawings. In a broad sense, PCB board maintenance is applicable to any equipment board card. At present, affected by technology, cost, market demand and other factors, PCB board maintenance mainly refers to chip level maintenance of advanced products, including touch screen maintenance, instrument maintenance, server maintenance, industrial computer maintenance, CMM maintenance, injection molding machine PCB board maintenance, embroidery machine PCB board maintenance, CPU board maintenance, industrial control products, etc. Among them, the industrial control non map non-destructive maintenance technology advocated by Shenzhen Yuanfa Industrial Control Maintenance Co., Ltd. is currently recognized as a more scientific technical indicator in the pcb industry.

Maintenance steps

Each PCB board maintenance engineer has different judgment methods and maintenance ideas. However, the maintenance steps can be summarized into the following six steps. To understand the board maintenance, first understand the fault condition, and then determine the fault within a SMAller range, which is conducive to the maintenance work. Therefore, understanding the fault condition of the PCB board is very important to start the maintenance.

Observation of folding board

Board observation is also a preliminary study, which aims to understand what input and output interfaces the board has, what functions the board realizes, and the distribution of various control parts of the board.

Folding line test

After the failure understanding and board observation are completed, the board is preliminarily detected according to the actual situation. The circuit detection may not be able to find the failure point of the board, but the experienced PCB board maintenance personnel can eliminate a wide range of failures through detection, paving the way for the next maintenance.

Inspection of folding components

For the inspection of components, most components need to be removed from the PCB board by soldering iron, and then inspected by professional equipment. This process will damage the external integrity of the PCB board, so generally, maintenance personnel will not remove components at will.

Folding fault maintenance

Through circuit testing, component testing and other work, the fault found shall be handLED, including circuit repair, component replacement, transformation and other work.

Folding test

The board that has completed the maintenance needs to be tested again. After confirming that there is no fault, it can be tested on the computer. Maintenance tools

Tools for PCB board maintenance include general tools and professional tools. General tools include multimeter, oscilloscope, soldering iron, hot air gun, BGA soldering station, PCB board detector and other tools. The professional tools are mainly Huineng PCB board maintenance tester.

The main application instruments for PCB board maintenance are mainly Keyu Digital Integrated Circuit Tester and Keyu Analog Integrated Circuit Tester. These two instruments are mainly used to test the quality of digital integrated circuits and analog integrated circuits in PCB boards. There is also a capacitance meter: used to detect the quality of capacitors on the PCB board; Keyu Short Circuit Tracker: used to determine and locate the cause of short circuit fault in PCB boards.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱