Five kinds of printed circuit boards improve the scientifIC and technological level

The key task of China's copper clad laminate (CCL) industry in the future development strategy, especially in terms of products, should be to produce printed circuit boards on five new types of substrates, that is, through the development of five new types of substrates and technological progress This breakthrough has improved the scientific and technological level of copper clad laminate in China The development of these five new high-performance CCL products listed below is a key topic for Chinese CCL industry engineers and scientific and technological personnel in future research and development

Printed circuit board

Lead free compatible copper clad laminate

At the EU meeting on October 11, two "European Directives" containing environmental protection were adopted. They will be fully implemented on July 1, 2006. These two "European Directives" refer to the "Waste Electricity and Electronic Products Directive" (WEEE for short) and the "Restriction on the Use of Certain Hazardous Substances" (RoHS for short), which prohibit the use of leaded materials. Therefore, the way to solve these two problems is to develop lead-free copper clad laminate as soon as possible.

High performance copper clad laminate

The high-performance copper clad laminates mentioned here include low dielectric constant (Dk) copper clad laminates, copper clad laminates for high-frequency and high-speed printed circuit boards, high heat resistance copper clad laminates and various substrates (resin coated laminates) for multilayer boards. Copper foil, organic resin film forming the insulating layer of laminated Multilayer board, glass fiber reinforced or other organic fiber reinforced prepreg, etc.). In the next few years (until 2010), when developing this high-performance copper clad laminate, according to the prediction of the future development of electronic installation technology, the corresponding performance index value should be reached.

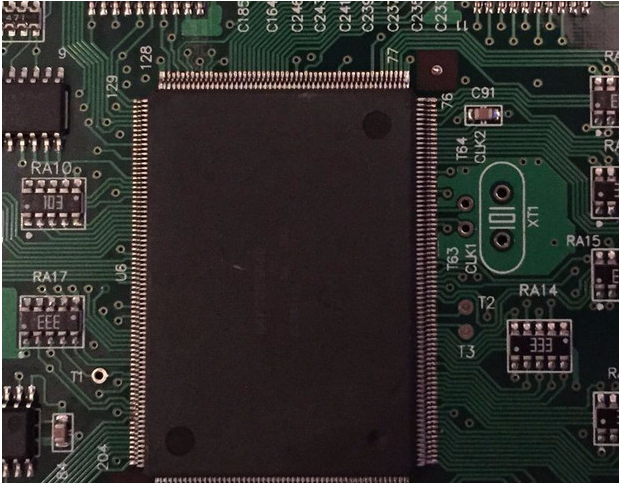

Integrated circuit packaging carrier substrate information

The development of IC packaging carrier substrate materials (also known as IC packaging substrate) is a very important topic at present. This is also an urgent need for the development of integrated circuit packaging and microelectronics technology in China. With the development of IC packaging towards high frequency and low power consumption, IC packaging substrate will be improved in such important aspects as low dielectric constant, low dielectric loss factor and high thermal conductivity. An important topic for future research and development is the thermal connection technology of substrate - effective thermal coordination and heat dissipation integration. In order to ensure the freedom of IC packaging design and the development of new IC packaging technology, it is necessary to conduct model testing and analogy testing. These two tasks are of great significance to master the characteristic requirements of IC packaging substrate data, namely, its power efficiency, heating and cooling efficiency, reliability and other requirements. In addition, further communication should be made with the IC packaging design industry to reach a consensus. The characteristics of the developed substrate data shall be provided to the designers of complete electronic products in a timely manner, so that the designers can establish an accurate and advanced data base. It is also necessary to solve the problem that the thermal expansion coefficient of integrated circuit packaging carrier is inconsistent with the transistor chip. Even in multilayer laminates suitable for microcircuit manufacturing, there is a problem that the thermal expansion coefficient of insulating substrate is usually too large (usually, the thermal expansion coefficient is 60ppm/C). The thermal expansion coefficient of substrate is about 6ppm, which is close to the thermal expansion coefficient of transistor chip. This is really a "problem" in substrate manufacturing technology. In order to adapt to the rapid development, the dielectric constant of the substrate should reach 2.0 and the dielectric loss factor can be close to 0.001. For this reason, it is expected that a new generation of printed circuit boards will appear in the world around 2005, surpassing the boundaries of traditional substrate materials and traditional manufacturing technologies. The breakthrough in science and technology is first in the use of new substrates.

Looking forward to the future development of IC packaging design and manufacturing technology, there is a stricter requirement for the substrate materials used. This is mainly reflected in the following aspects:

1) High time (Tg) efficiency corresponding to lead-free flux.

2) The low dielectric loss factor matching the characteristic impedance is realized.

3) Low dielectric constant corresponding to high speed (? μ should be close to 2).

4) Low warpage (improve the flatness of the substrate surface).

5) Low moisture absorption.

6) Low coefficient of thermal expansion, making the coefficient of thermal expansion close to 6ppm

7) Low cost of integrated circuit packaging carrier board.

8) Low cost substrate containing components.

9) In order to improve the thermal shock resistance, the basic mechanical strength is improved. The substrate data is suitable for high and low temperature cycling without reducing efficiency.

10) In order to achieve low cost, the green substrate data is applicable to high reflux temperature. The special function copper clad plate mentioned here mainly refers to metal base (core) copper clad plate, ceramic base copper clad plate, high dielectric constant plate, copper clad plate (or substrate data) for embedded passive component multilayer plate, copper clad plate for optical circuit substrate, etc. The development and production of this kind of CCL is not only the need of new technology development of electronic information products, but also the need of the development of China's aerOSPace industry.

High performance Flexible copper clad laminate

Since large-scale industrial production, flexible printed circuit board (FPC) has experienced more than 30 years of development. In the 1970s, FPC began to enter the real industrial mass production. In the late 1980s, due to the emergence and application of new polyimide film materials, adhesive free flexible circuit boards (commonly referred to as "double-layer Flexible circuit boards") appeared. In the 1990s, a photosensitive coating corresponding to high-density circuits was developed in the world, which has greatly changed the design of fuel cells. Due to the opening of new application fields, the concept of its product form has undergone great changes and has been expanded to a wider range, including table board gaMES and round bread boards. The high-density flexible circuit boards appeared in the second half of the 1990s began to enter large-scale industrial production. Its circuit mode has rapidly developed to a more refined level. The MARKet demand for high-density FPCs is also growing rapidly. At present, the global FPC annual output value is about 3 billion to 3.5 billion US dollars. In recent years, the global production of FPCs has been increasing. Its proportion in PCB is also increasing year by year. In the United States, China and other countries, the proportion of FPC in the total PCB output value has reached 13% - 16%. Flexible circuit board (FPC) is becoming a very important and indispensable variety in Printed Circuit Board (PCB). There is a big gap between the flexible copper clad laminate and the world's advanced countries and regions in terms of production scale, manufacturing technology level, raw material manufacturing technology, etc. This gap is even larger than that of the rigid copper clad laminate.

The development of CCL and PCBs should be synchronized

Copper clad laminate (CCL), as the substrate information in PCB manufacturing, mainly plays the role of interconnection, heat insulation, and support for PCB, and has a great impact on the transmission rate, energy loss, and the characteristic impedance of the signal in the circuit Therefore, the efficiency, quality, processability in manufacturing, manufacturing level, manufacturing cost, long-term reliability, and stability of printed circuit boards largely depend on the CCL data The technology and production of CCL have experienced more than half a century of development At present, the global annual output of CCL has exceeded 300 million square meters Copper clad laminate has become an important part of the basic data of electronic information products Copper clad laminate manufacturing is a new industry With the development of electronic information and communication industry, it has broad prospects The development of electronic information technology shows that CCL technology is one of the key technologies to promote the rapid development of electronic industry The development of CCL technology and production is synchronized with the development of electronic information industry, especially the printed circuit board industry This is a process of constant innovation and pursuit The innovation and development of electronic complete products continuously promote the progress and development of CCL, transistor manufacturing technology, electronic installation technology, and printed circuit board manufacturing technology The rapid development of electronic information industry makes electronic products develop towards miniaturization, functionality, high performance, and high reliability From the general Surface Mount Technology (SMT) in the mid-1970s to the high-density interconnect surface mount technology in the 1990s, as well as the application of various new packaging technologies in recent years, such as transistor packaging and integrated circuit packaging, electronic installation technology continues to develop towards high-density At the same time, the development of high-density interconnection technology has promoted the printed circuit board s in the high-density direction The development of installation technology and printed circuit board technology has made continuous improvement in CCL technology, which is a printed circuit board It is estimated that the average annual growth rate of the world's electronic information industry in the next 10 years will be 7.4% By 2010, the world electronic and information industry market will reach 3.4 trillion US dollars, including 1.2 trillion US dollars for electronic equipment. Communication equipment and computers will be responsible for this More than 70% of the total, reaching US $0.86 trillion It can be seen that the huge market of copper clad laminate as electronic basic data will not only continue to exist, but also continue to develop at a growth rate of 15% Relevant information released by the Central Control Room Industry Association shows that in the next five years, in order to adapt to the development trend of high-density British Geological Society technology and transistor packaging technology, the proportion of high-performance thin page 4 and high-performance resin substrate will be added to the printed pcb in the future

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱