Reasons and Basis for SMT Proofing to Charge Startup Fee and Engineering Fee

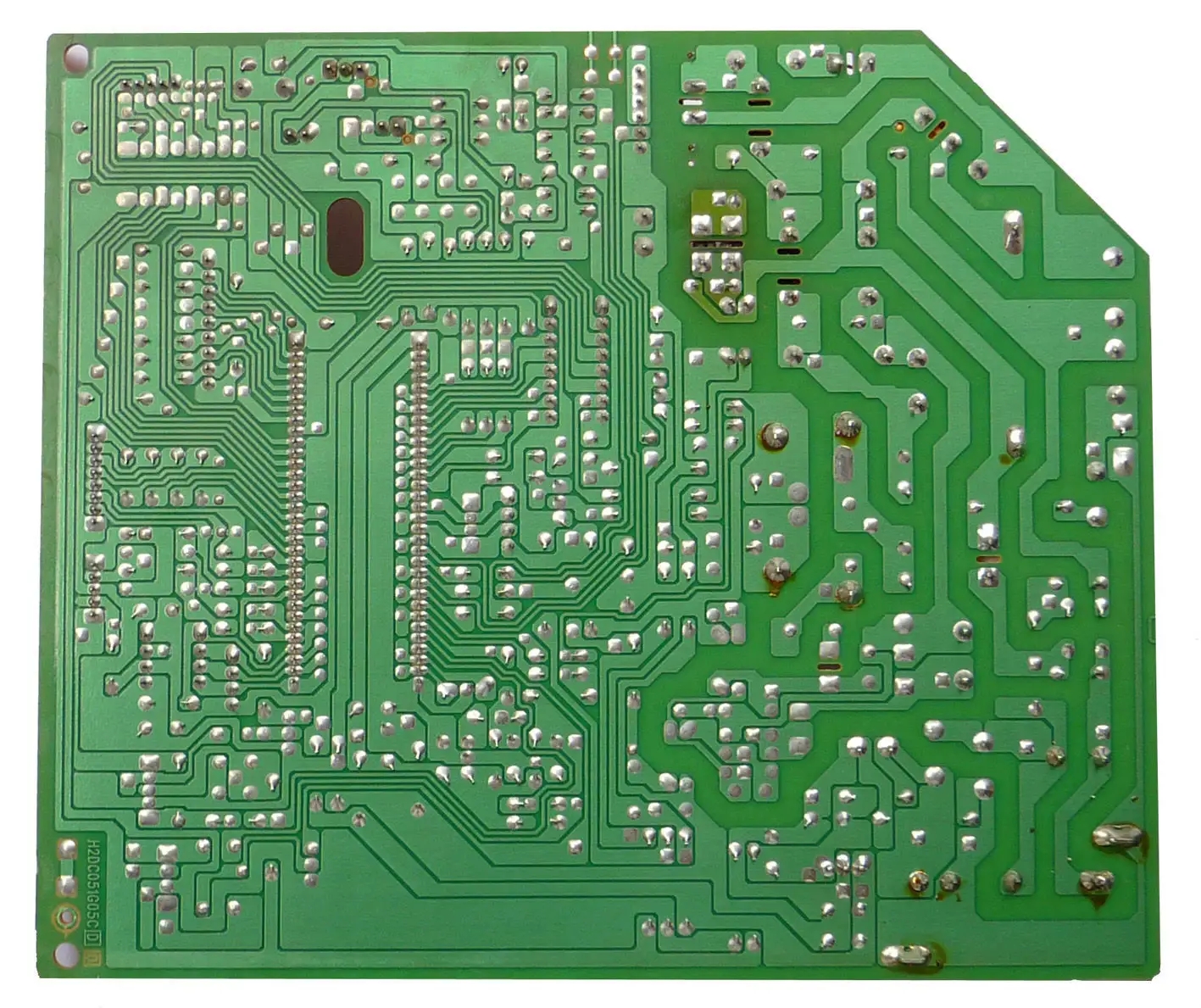

SMT chip processing is to mount electronIC components on PCB bare board and realize welding through successive processes.

First, print the solder paste of the welding material on the bonding pad of the bare PCB

Then, use the placement machine to mount the electronIC components onto the bonding pads of the PCB bare board (these pads have solder paste, which has a certain viscosity, and can stick to the electronic components)

Next, send PCB board to reflow soldering for soldering

Finally, use AOI detector to check the welded PCB to ensure that there are no welding defects. This process is calLED SMT chip processing

When electronic product R&D enterprises carry out SMT proofing or SMAll batch production in PCBA processing plants, they often hear about start-up costs and engineering costs. SMT chip processing requires fast and efficient production. Generally, SMT chip workshops will carry out non-stop production. Stopping the machine to replace it will increase production costs and reduce profits. Therefore, small batches of orders often charge startup fees.

1、 The high charge for small batch processing of SMT proofing mainly refers to time loss, not startup loss. That is to say, before SMT chip processing, whether it is large-scale SMT chip processing or small-scale SMT chip processing, the preliminary work needs to be done is the same, such as SMT chip machine programming, PCB positioning, and first article confirmation after startup. In fact, the time of patch processing is very short. Therefore, when the amount is small, the so-called loss is more time loss. The project cost refers to the production of data files, the production of steel grids, the commissioning of equipment, the replacement of SMT lines, etc. Because the order is too small to reach the minimum consumption level, the customer needs to bear these project costs.

2、 Under the same time cost, the production efficiency of mass SMT chip processing is higher, and there is no need to waste time on the preliminary work in the morning or after the production. SometiMES customers will take it for granted that the price will be very cheap if the quantity is small. In fact, this is not the case. The preliminary work of large batch SMT processing is the same as that of small batch processing. SMT mounter programming, PCB positioning, and first article confirmation after startup are the same, as long as the mounter is debugged. Therefore, engineering fees will be charged for small batch processing, or start-up fees in some places. Otherwise, the quantity is too small, which is not enough for labor cost and machine loss, and the time spent in and out is basically wasted. This is the reason for the high cost of small batch processing of SMT proofing.

PCB manufacturers, PCB designers and PCBA manufacturers explain the reasons and basis for SMT proofing to charge startup fees and engineering fees.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱