SMT SMT component layout and processing flow of incoming material mode

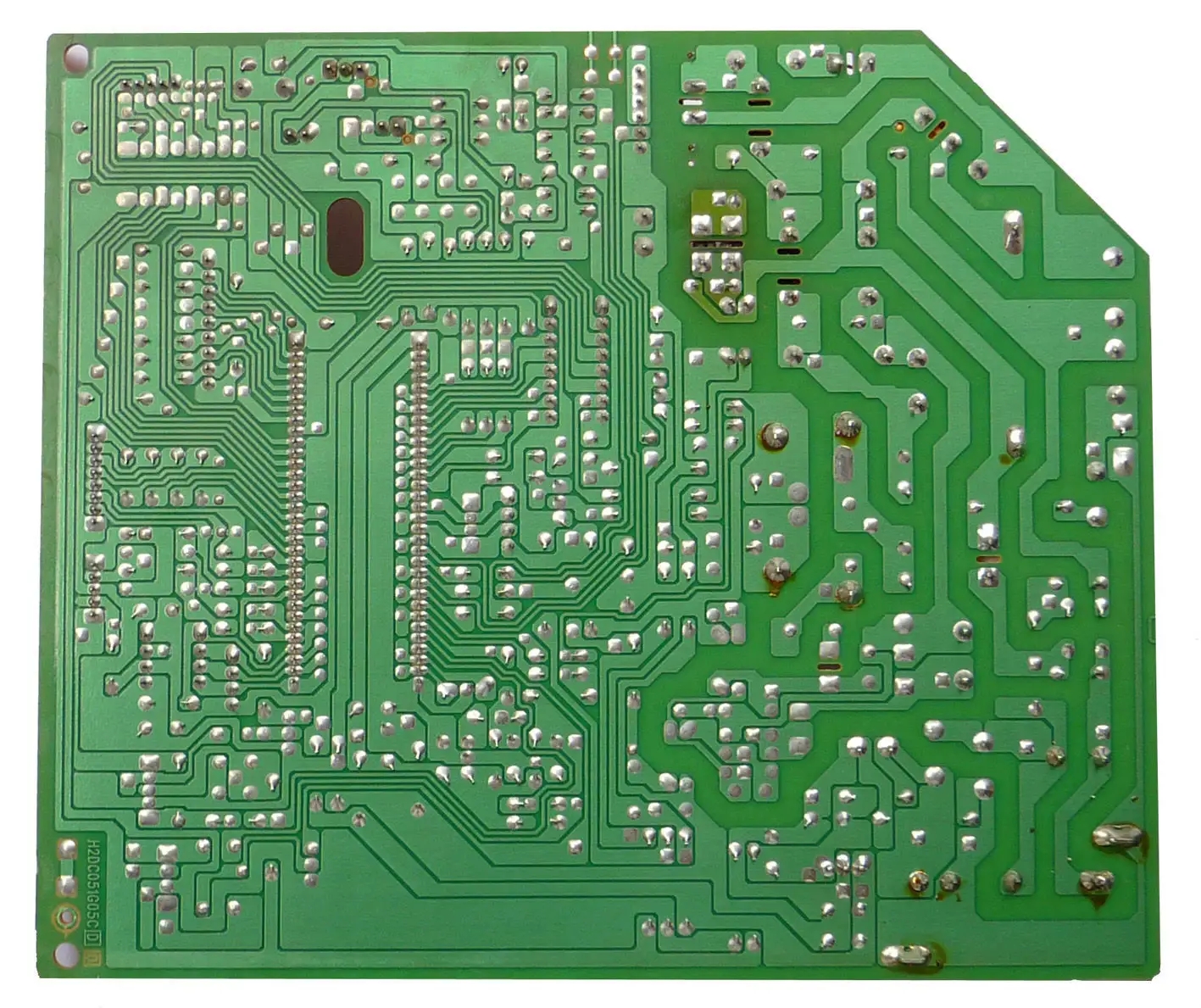

SMT chip processing has requirements for PCBA to design the layout of chip components. Reasonable layout planning will help in the process of processing and production. If the layout problem does not consider the actual processing situation at will, it will cause some problems in production, and different processing methods have different layout requirements.

Layout requirements of SMT components for SMT chip processing

1. Replaceable and adjustable components. In case of components and parts that need to be replaced or adjusted frequently, it is necessary to consider the characteristICs and requirements of the whole machine and place them at the position where they can be easily replaced.

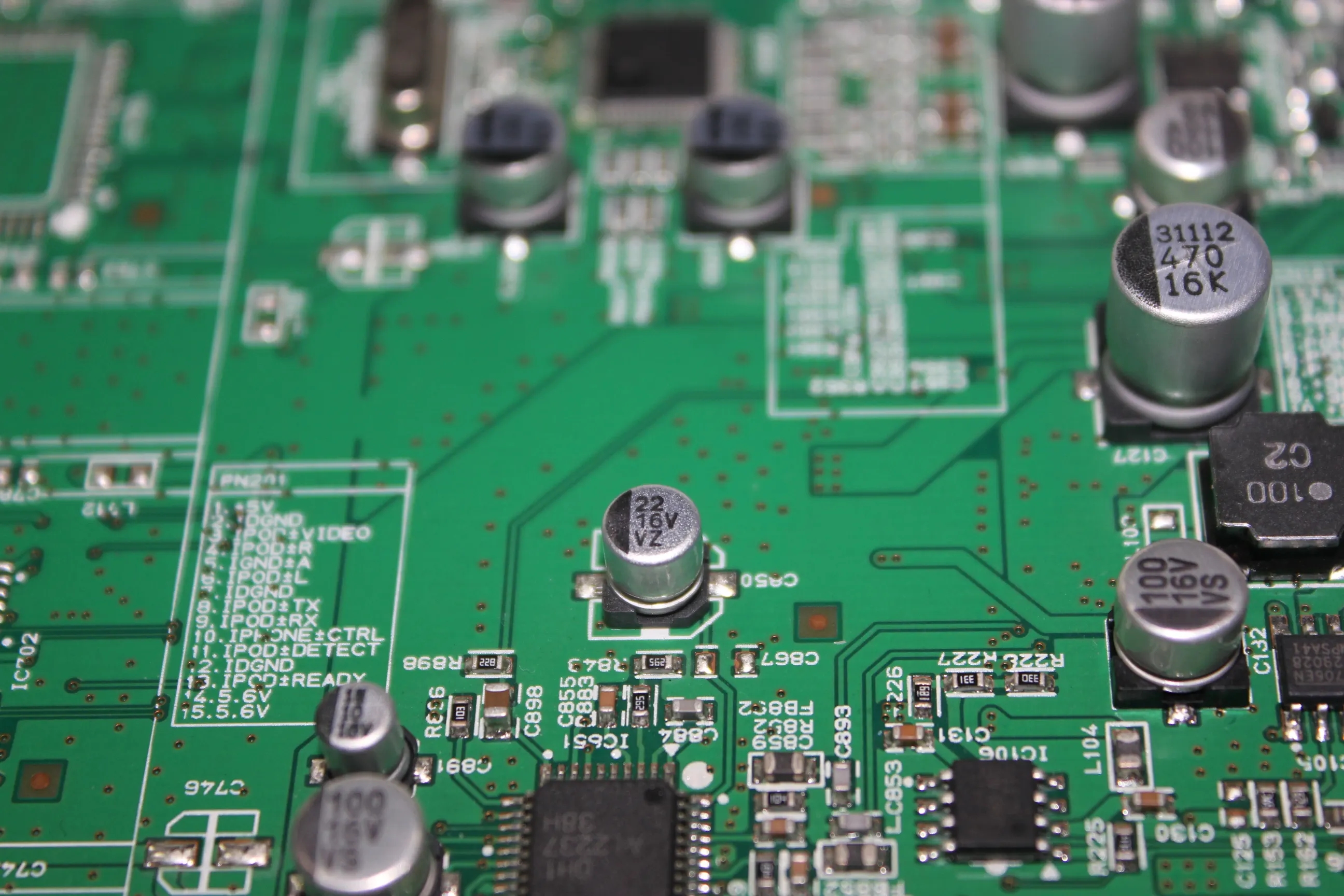

2. During the mounting process of temperature sensitive components, if temperature sensitive components are encountered, they must be kept away from heating components, such as triodes, integrated circuits, electrolytic capacitors, etc., as well as high-power components, radiators and high-power resistors.

3. Arrangement direction: In the actual processing of SMT chip, the arrangement direction of SMT components is also required. Try to keep the same direction, and the feature direction should be consistent, so as to facilitate the later installation, welding and detection. In particular, the number printing direction of components must be the same.

4. The distribution is balanced. The thermal capacity of high quality SMT components will be greater than that of general components during reflow processing, which will lead to local temperature difference and even false soldering problems. Keeping the distribution balanced in SMT chip processing can avoid such problems, and can also keep the balance of the circuit board.

5. Heating components. Different components will affect other components when they are contacted together. For example, heating components are generally placed at corners and ventilated positions to facilitate heat dissipation. The heating element must be supported by other leads or supports, and must keep a certain distance from the surface of the printed circuit board. The minimum distance must not be less than 2mm, otherwise the quality of the printed circuit board will be affected.

SMT processing incoming material mode processing flow

There are many modes of SMT processing, such as SMT OEM and incoming material processing. Different processing cooperation modes have different processes, and the corresponding customers need to prepare different things. The biggest difference between incoming material processing and SMT outsourcing is that customers need to prepare materials for incoming material processing, while outsourcing can hand over the procurement of boards and components to PCBA processing plants. Quality is always the most important indicator for all electronic processing plants, and so is incoming processing..

SMT processing incoming material mode processing flow

1、 Both parties have detaiLED discussions on the SMT processing project and signed a cooperation contract after confirmation.

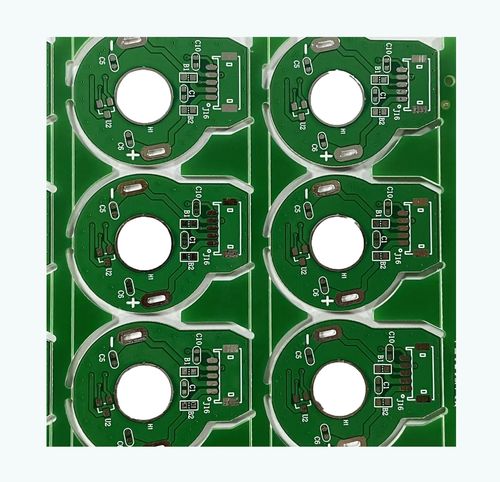

2、 Customers need to provide PCB files, Bom lists, component materials, etc. PCB files and BOM lists are used to confirm whether the mounting direction of components and materials are accurate.

3、 Incoming inspection and processing. IQC inspection shall be carried out for materials to ensure production quality. For some components, material processing shall be carried out, such as material trimming, component molding, etc.

4、 Go online for production. First article proofing will be carried out before online production, and mass production will be carried out after confirmation by both parties. During this period, steel MESh production, solder paste printing, component mounting, reflow process and red glue process will be carried out.

5、 Finished product inspection. The products shall be delivered to the Quality Department for sampling inspection, and shall be packaged and delivered out of the warehouse after the power is qualified.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the layout of SMT SMT components and the process flow of processing incoming materials.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱