Improve the production and sales rate of the placement machine?

The mounter is suitable for PCB circuit assembly in the field of industrial electronIC equipment and military electronic equipment Let me share with you how to improve the production and sales rate of the SMT machine production line?

1、 Handling of resettlement plan

The production line is composed of several equipment, including solder paste printer, chip mounter, reflow soldering, etc, But in fact, the speed of the production line is determined by SMT mounter The SMT production line usually includes high-speed machine and high-precision SMT machine The former mainly installs chip modules, while the latter mainly installs integrated circuits and special-shaped components When the two placement machines complete a placement process (hereinafter referred to as placement time) at the same time and the SMAllest, the entire SMT production line has given full play to its production capacity To achieve this goal, we can process the placement process as follows

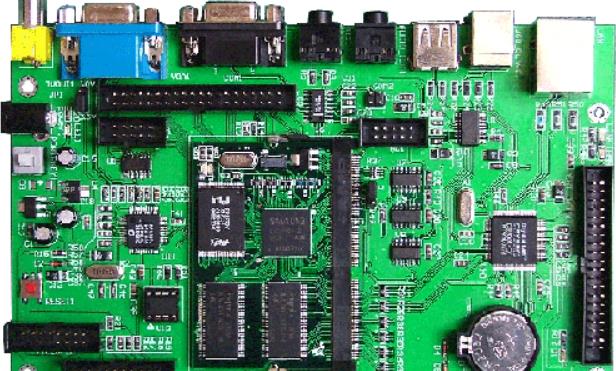

Circuit board

1. Load distribution is balanced. Reasonably allocate the number of placement components for each equipment, and try to make the placement of each equipment always uniform. When we first allocate the number of components to be placed on each device, it usually seems that the distance between placement tiMES is relatively large. This requires adjusting the production load of all equipment on the production line according to the placement time of each equipment. Move some parts of the equipment that has been instalLED for a long time to another equipment to complete load distribution balancing.

2. Equipment optimization. Each mounting machine has a maximum mounting speed value. The speed claimed by many patch machine manufacturers cannot be achieved in practice, but in practice, the speed value must be completed under certain conditions. The purpose of optimizing the NC program of each equipment is to make the placement machine meet these conditions as much as possible in the production process, and then complete the placement at the highest speed to reduce the placement time of the equipment. The optimization criteria depend on the structure of the equipment.

2. Eliminate bottlenecks

This SMT production line is composed of multiple automation equipment When the speed of a device is lower than that of other devices, then the device will become the bottleneck of the SMT production line that limits the speed increase of the whole system Usually, the bottleneck usually appears on the mounter The bottleneck can only be eliminated by adding a chip mounter Of course, this requires a lot of capital investment, but it can make full use of the excess production capacity of other equipment, which is much more cost-effective than investing in another company's SMT production line Which type of mounter to add depends on the bottleneck of the production line Under normal circumstances, it is better to buy a high-speed, multi-function mounter, because it has the characteristics of high-speed and high-precision machines The scale of the equipment covers high-precision machines and high-speed machines. It can handle bottlenecks caused by high-speed machines or high-precision machines Now the development trend of SMT is also moving in this direction to meet the needs of shopping malls

Adding the mounter to the production line can handle bottlenecks and speed up the pace. This method provides more production capacity and more feeder positions, so as to better balance the production line without significantly increasing the complexity of production line management, which is far greater than the increased production capacity of adding a separate mounter.

3. Implement strict and effective treatment methods

SMT equipment is a kind of electromechanical fine equipment. It is an important way to improve the power of SMT production line to implement strict and effective treatment methods in operation. For example, components requiring pre compensation are installed on the standby feeder; The production line installs the last few pieces of the previous batch together, and prepares the next batch of products on the production line, etc.

SMT production line is a large production line, and the output is calculated in seconds. In addition to equipment and environmental factors, production smoothness and product quality, human factors play an extremely important role in improving production capacity. Special attention should be paid to staff training. In addition to regular professional skills training, professional SMT books and magazines also organize staff to learn textbooks, cultivate their love for SMT, and improve everyone's overall professional level.

Regular inspection and maintenance of SMT equipment is also a strong guarantee to ensure its full effectiveness Due to heavy production tasks, many companies tend to ignore this point in the production process Once the equipment cannot be produced normally due to failure, the loss caused by strike is far greater than the cost of regular shutdown inspection and maintenance of equipment We must regularly conduct scientific inspection and maintenance of the equipment to keep the equipment in good condition

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱