Details and usage of manual and automatIC SMT

Four Details Used SMT Mounter

Surface Mount Technology is used for parts production and assembly processing equipment. Many manufacturers now use SMT mounters, but various problems and errors will occur when using them. The following are four details that should be paid attention to during the processing of the SMT machine.

Temperature and humidity: SMT production workshop has many instruments and equipment The placement machine is a precision equipment, which is more sensitive to the difference of temperature and humidity Therefore, according to the regulations of the power processing workshop, the temperature of the SMT chip processing equipment should be controlLED within 25 ± 3 ° C, and the humidity between SMT chips placed on the locomotive should be controlled at 0. Relative humidity 01%

Second, professional operators: locomotive repair should be a very detailed process. If you are not a qualified operator, it is easy to discard parts and omit parts because the details of control are not in place. In this case, operators need to receive professional training and then formally take up their posts. Trained personnel can not only increase productivity, but also increase output.

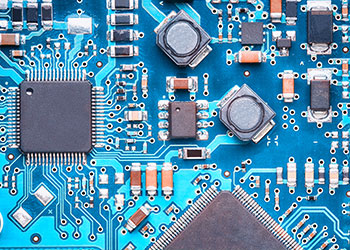

Circuit board

Third, correct use of solder paste: the volume ratio of the most commonly used tin powder particles in the solder paste used for wafer processing is about 1:1. Starting from SMT chip machining, the solder paste should be gently and thoroughly stirred. Most importantly, the temperature cannot be recovered by abnormal temperature.

Fourth, PCB storage method: After PCB processing, if the customer does not pick up the goods in time or needs temporary storage, first pay attention to the storage method of smt pcb. After considering the transportation route of GG customers, please select the appropriate packaging and grade. Pay attention to the dryness and humidity of the environment to avoid adding moisture and oxidation to the peel during the harsh process, and do not apply these three anti paint products.

Manual and automatic SMT mounting assembly steps

Many of our important customers have contacted us to understand the exact process of assembling Bittle's SMT Circuit Board. Qualified BITTLE engineers will follow the defined steps during PCB assembly. Our PCB assembly process includes PCB surface treatment, part placement, welding, cleaning, inspection and testing. Our well-trained assembly technicians will operate in strict accordance with the prescribed procedures and use modern component placement methods to assemble circuit boards. We use manual and automatic technology SMT placement to position PCB components.

Normally, through hole parts are placed manually, while surface mounted components are placed using a pick and place machine. In most cases, automatic assembly is not feasible for a SMAll number of PCBs. The welding methods used by our team are wave soldering of through-hole components and reflow soldering of surface mounted components. During through-hole assembly, place the parts on the PCB and use wave soldering to weld the wires of the through-hole assembly.

During SMT assembly, solder paste is applied to PCB through welding fixture, then parts are placed in pads, and processed in reflow furnace to melt solder paste. In addition, in hybrid technology, PCB requires soldering and reflow. After the circuit board is welded, our team will clean it. We use the latest technology to clean the assembled circuit board to remove all flux debris. In addition, different technologies are used to remove flowing debris, which is usually a combination of detergent, stirring and heating.

Then send the circuit board for detailed inspection to verify the precise placement of the components. Use the most advanced inspection tools to verify the quality of the assembly plate. Some of the technologies used include sample inspection, automatic optical inspection (AOI), X-ray inspection, etc. After detailed quality test, the printing plate will be delivered to the final customer.

NeoDen has provided a complete SMT solution for the assembly line, including reflow furnace SMT machine wave soldering machine, selection and placement, printer solder paste, charger PCB, unloader PCB, vertical chip, placement machine AOI, machine SMTSPI, machine SMT perspective equipment smt assembly line, PCB production equipment

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱