PCBA circuit board processing and throwing

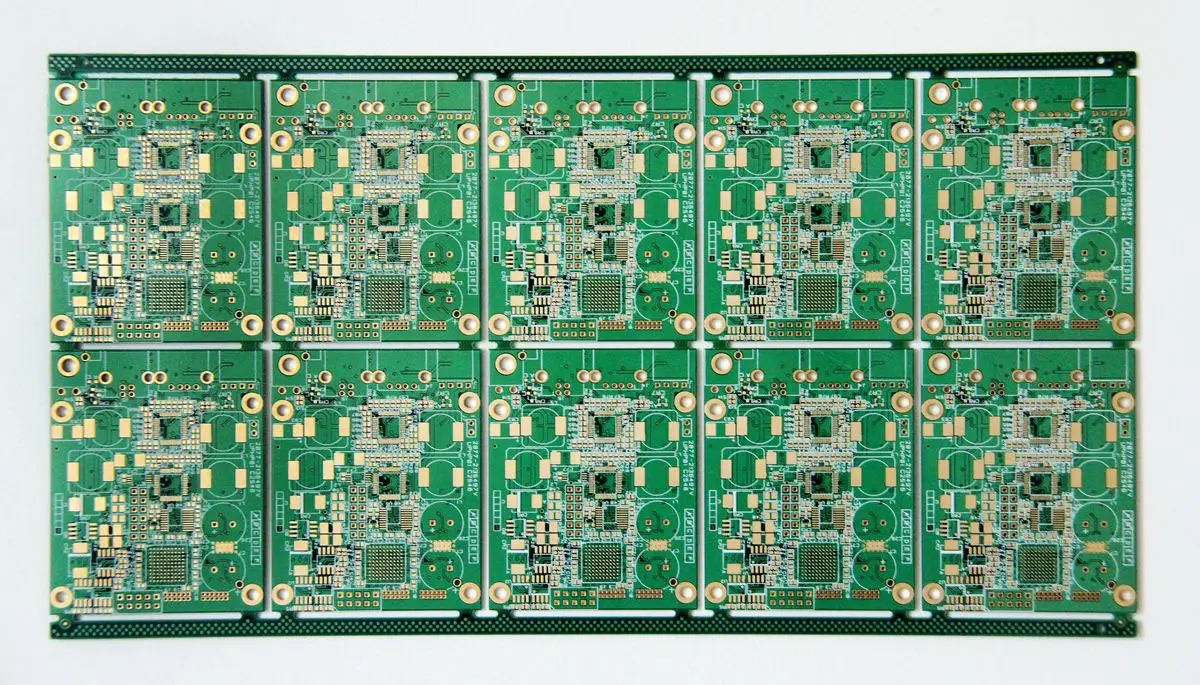

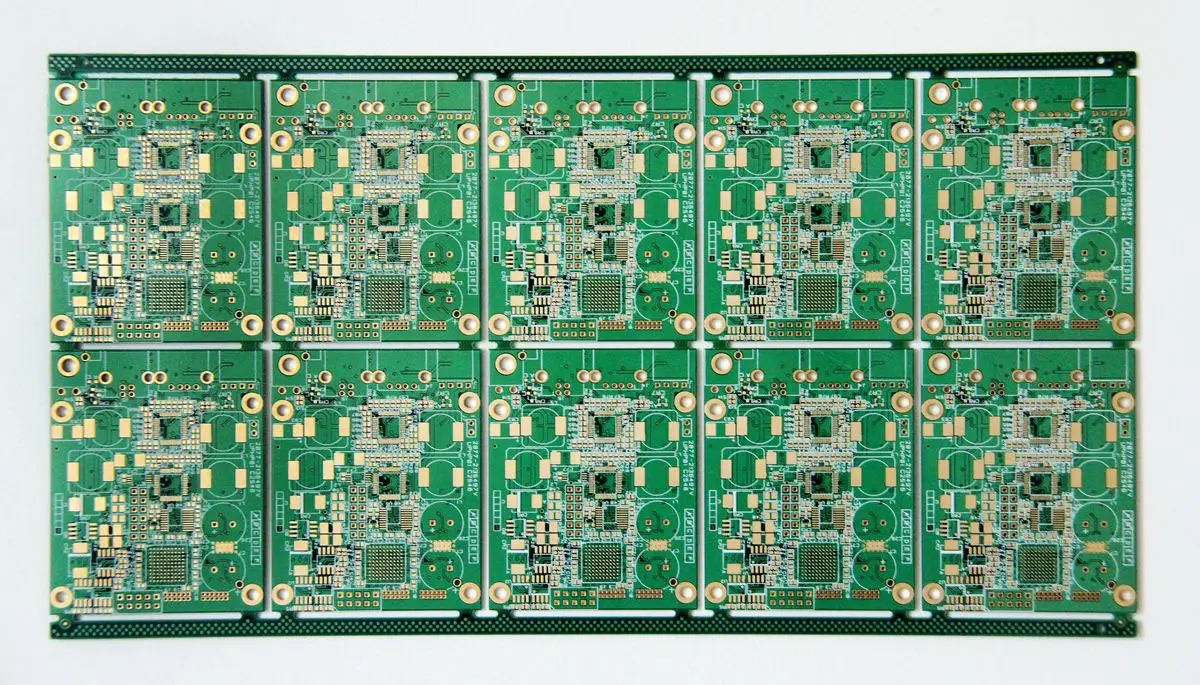

PCBA circuit board processing is an indispensable step in the design and production process of electronIC equipment. PCBA circuit board carries the control system of electronic equipment, and its quality directly affects the operation and product quality of electronic equipment. A good product can not be separated from the support of high-quality PCBA circuit board. In the process of PCBA circuit board processing, it is inevitable to encounter some

PCBA circuit board processing is an indispensable step in the design and production process of electronic equipment. PCBA circuit board carries the control system of electronic equipment, and its quality directly affects the operation and product quality of electronic equipment. A good product cannot be separated from the support of high-quality PCBA circuit board. In the process of PCBA circuit board processing, some problems will inevitably be encountered. Let's learn about the causes and solutions of PCBA dumping.

Reasons and Solutions of PCBA Circuit Board Processing Throwing

Cause 1: problems with suction nozzle, such as deformation, blockage and damage of suction nozzle, resulting in insufficient air pressure and air leakage, resulting in failure of material suction, improper material collection, failure of identification and PCBA throwing.

Countermeasures: Clean and replace the suction nozzle.

Cause 2: The feeder is faulty, the feeder is set incorrectly, the position is deformed, and the feeding mechanism is poor, which causes the material cannot be picked up or PCBA throws the material due to poor picking.

Countermeasures: reset the packer, clean the equipment, calibrate or replace the packer.

Cause 3: identification system problems, poor vision, uncleanness of vision or laser lens, foreign matters interfering with identification, improper selection of identification light source or insufficient intensity and gray scale, or the identification system may be broken.

Countermeasures: Clean and wipe the surface of the identification system, keep it clean and free of foreign matters and oil contamination, adjust the intensity and gray level of the light source, and replace the identification system components.

Cause 4: position problem, position deviation, the suction nozzle is not at the center of the material when sucking and reclaiming, and the reclaiming height is incorrect (generally subject to 0.05mm of pressing down after touching the parts), which causes deviation, incorrect reclaiming, and deviation. When identifying, it is inconsistent with the corresponding data parameters and is discarded as invalid material by the identification system.

Countermeasures: Adjust the parameters such as reclaiming position and height.

Cause 5: Vacuum problem, insufficient air pressure, unsmooth vacuum gas pipe passage, foreign matter blocking the vacuum pipe, or insufficient air pressure due to vacuum leakage, or falling off on the way to remove the sticker.

Countermeasures: Adjust the air pressure steep slope to the required air pressure value of the equipment (generally 0.5~0.6 Mpa for the patch mounting machine), clean and dredge the air pressure pipeline, and repair the leaking air path.

According to relevant research, static electricity is also a cause of PCBA throwing, so the placement machine should be grounded and the production site should be anti-static.

It is normal for the placement machine to have PCBA dumping, but if the PCBA dumping rate is high, it will seriously affect the production efficiency and production cost, which must be resolved. In case of serious PCBA dumping, you can first ask the on-site personnel, and then observe and analyze the above seven reasons to find out the problem directly, so that you can find out the reason more effectively, solve it, and improve the production efficiency, without taking up too much machine production time.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱