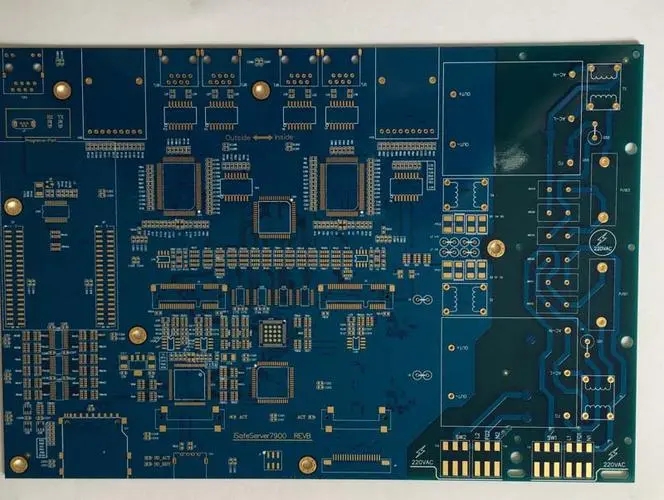

PCB mounting process, packaging form, production capacity and PCB design

PCB manufacturing, PCB design and PCBA processing manufacturers will explain PCB mounting process, packaging form, production capacity and PCB design

The production process and packaging form are closely related to the design for manufacturability of PCB. It is also necessary to understand the production capacity of enterprises.

1. Relationship between SMT and PCB design

The so-calLED Surface Mount Technology refers to a technology about how to assemble substrates and components through effective process materials and processes, and ensure a good life.

2. PCB Design and IC chip Packaging

Nowadays, the electronIC technology, especially the microelectronic technology, has been developed rapidly. Large scale and ultra large scale integrated circuits are increasingly used in general systems. Nowadays, the wide application of deep submicron production technology in IC makes the scale of chip integration even larger. As a PCB designer, we must understand various manufacturing processes and characteristics of IC chips, so as to better guide the design for manufacturability of PCB.

Packaging form refers to the shell of IC chip. It not only plays a role in installation, fixation, sealing protection and enhancing the electrical conductivity, but also connects with the package housing pins with wires through the contacts on the chip, and these pins are connected with other components through the wires on the PCB. An important indicator to measure a chip packaging technology is the ratio of chip area to packaging area. The closer this value is to 1, the better this chip packaging technology is. Generally speaking, the emergence of a new generation of CPUs is accompanied by a new packaging form.

At present, according to the chronological order of technology appearance, the packaging technologies of IC chips mainly include dual in-line package (DIP), SMAll size package (SOP), plastic quad outlet flat package (PQFP), ball grid array (BGA) package, chip size package (CSP) and multi chip set (MCM) package. The following is a brief introduction to various specific packaging forms:

(1) dual in line package (DIP) is a popular packaging technology in the 1970s. It has the advantages of suitable for PCB perforation installation, easy PCB wiring and easy operation. DIP also has a variety of packaging structures: multilayer ceramic DIP, single-layer ceramic DIP and lead frame DIP. Among them, the lead frame DIP includes three types: glass ceramic package, plastic package structure and ceramic low melting glass package. The disadvantages of this packaging technology are large package size and low packaging efficiency. For example, the ratio of chip area to package area of a 40 I/O pin plastIC encapsulated dual in-line package CPU is 1:80, far less than 1. Typical chips adopting this packaging form include Intel 8086, 80286, etc.

(2) Small size package (SOP) plastic quad lead flat package (PQFP) This is a chip carrier package that appeared in the 1980s. It includes ceramic leadless chip carrier (LCCC), plastic led chip carrier (PLCC) Small Outline Package (SOP) and Plastic Quad Flat Package (PQFP). This chip carrier packaging technology greatly improves the packaging efficiency of the chip, and to some extent, overcoMES the shortcomings of the dual in-line packaging technology. For example, take a CPU with a four sided flat pack (QFP) as an example, its chip area to package area ratio can reach 1:7.8.

(3) BGA packaging Ball Grid Array Package (BGA) packaging technology is developed to meet the continuous improvement of the integration of silicon chips, as well as the stricter requirements for integrated circuit packaging and the sharp increase of I/O pin and chip power consumption.

3. Enterprise's production capacity and PCB design

Understand the actual production capacity of the enterprise and promote the important component of design for manufacturability management. This work includes quantitative inspection, planning and formulation of specification indicators for the capabilities of all equipment of the enterprise. PCB manufacturing, PCB design and PCBA processing manufacturers will explain PCB mounting process, packaging form, production capacity and PCB design.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱