The following is the improvement method for the hole breaking/plating problem in the use of PCB dry film:

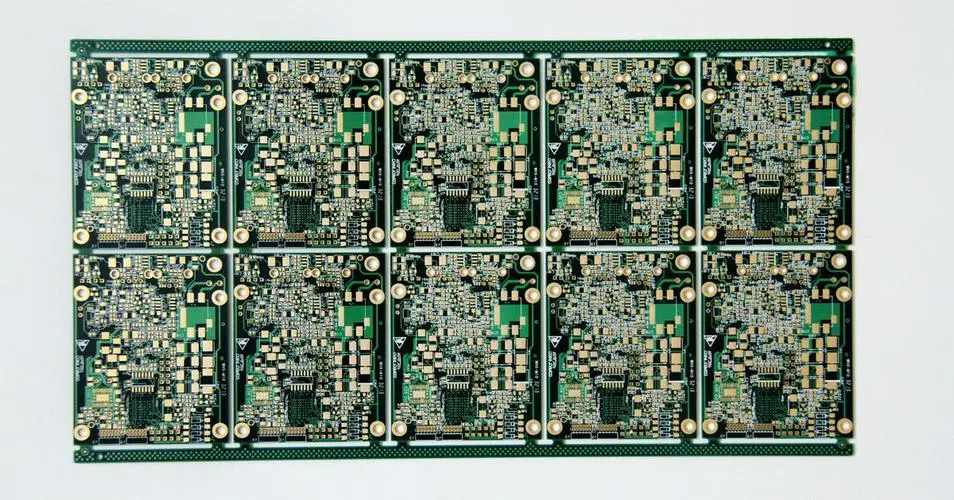

With the rapid development of the electronIC industry, PCB wiring is becoming more and more sophisticated. Most PCB manufacturers use dry film to complete the graphic transfer, and the use of dry film is becoming more and more popular. However, I still encounter many customers' mistakes when using dry film in the process of after-sales service, which is summarized for reference.

1、 The dry film mask is broken

Many customers believe that the temperature and pressure of the film should be increased to enhance its adhesion after the hole is broken. In fact, this view is incorrect, because the solvent of the corrosion resistant layer volatilizes excessively after the temperature and pressure are too high, which makes the dry film brittle and thin, and it is very easy to be broken when developing. We should always maintain the toughness of the dry film. Therefore, after the hole is broken, we can improve from the following points:

1. Reduce the film temperature and pressure

2. Improve the drilling edge

3. Improve exposure energy

4. Reduce the development pressure

5. The parking time after pasting the film shall not be too long, so as not to cause the sEMI fluid drug film at the corner to diffuse and thin under the effect of pressure

6. The dry film shall not be too tight during film application

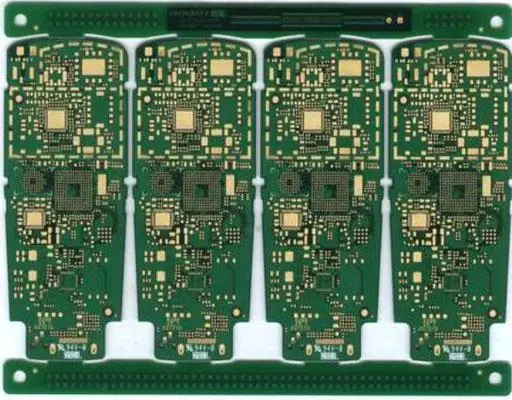

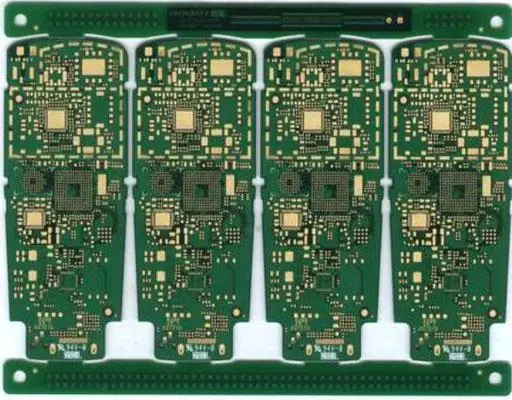

2、 Impregnation occurs during dry film electroplating

The reason for the plating is that the dry film and the copper clad foil are not firmly bonded, which makes the plating solution go deep and causes the "negative phase" part of the coating to become thicker. The plating of most PCB manufacturers is caused by the following factors:

1. High or low exposure energy

Under the irradiation of ultraviolet light, the photoinitiator absorbed light energy decomposes into free radical initiating monomer for photopolymerization, forming body molecules insoluble in dilute alkali solution. When the exposure is insufficient, due to incomplete polymerization, the adhesive film swells and becoMES soft during the development process, resulting in unclear lines or even PCB film falling off, resulting in poor film copper bonding; If the exposure is too high, it will cause development difficulties, and will also cause warping and peeling during PCB electroplating, forming infiltration. Therefore, it is important to control the exposure energy.

2. The film temperature is too high or too low

If the pasting temperature is too low, the adhesion between the dry film and the surface of the copper clad laminate is poor due to the insufficient softening and proper flow of the corrosion resistant film; If the temperature is too high, bubbles will be generated due to the rapid volatilization of the solvent and other volatile substances in the corrosion inhibitor, and the dry film will become brittle, which will cause warping and peeling during the electroplating shock, resulting in infiltration.

3. The film pressure is too high or too low

When the PCB film mounting pressure is too low, the film mounting surface may be uneven or there may be a gap between the dry film and the copper plate, which can not meet the binding force requirements; If the pasting pressure is too high, the solvent and volatile components of the PCB anti-corrosion layer will volatilize too much, which will cause the dry film to become brittle, and it will lift up and peel off after the electroplating shock.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱