Causes of PCB board deformation and dropping or tin cracking of PCB parts

PCB manufacturers, PCB designers and PCBA manufacturers explain the causes of PCB deformation and PCB parts falling or tin cracking

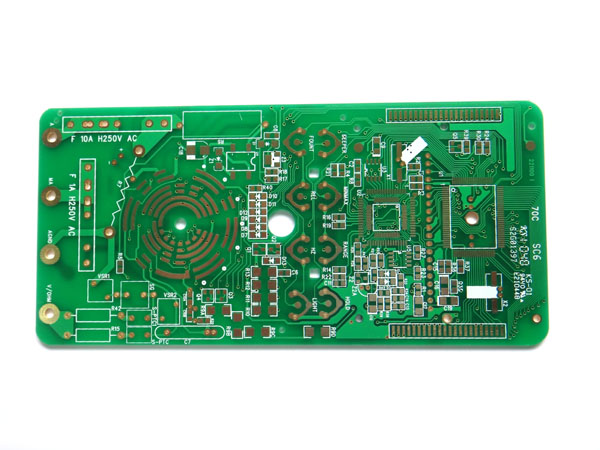

The uneven copper surface area on the circuit board will worsen the bending and warping of the board.

Generally, a large area of copper foil will be designed on the circuit board for grounding. SometiMES, a large area of copper foil will be designed on the Vcc layer. When these large areas of copper foil cannot be evenly distributed on the same circuit board, the problem of uneven heat absorption and heat dissipation will occur. Of course, the circuit board will also expand with heat and contract with cold. If the expansion and contraction cannot occur at the same time, it will cause different stresses and deformation, At this time, if the temperature of the circuit board has reached the upper limit of Tg value, the circuit board will begin to soften, causing permanent deformation.

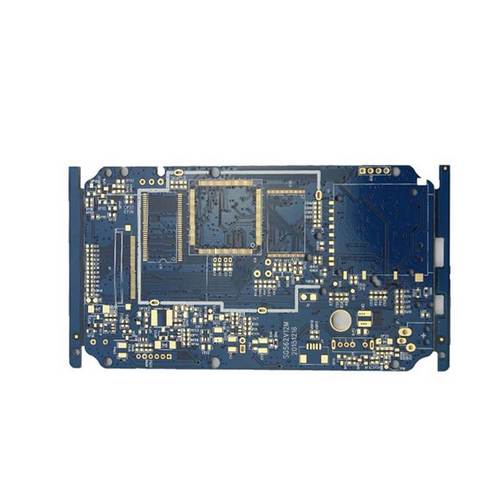

2. The connection points (vias) on each layer of the circuit board will limit the board's expansion and contraction.

Nowadays, most circuit boards are multilayer circuit boards, and there will be rivet like connection points (vias) between layers. The connection points are divided into through holes, blind holes and buried holes. Where there are connection points, the effect of expansion and contraction of multilayer circuit boards will be limited, and the bending and warping of circuit boards will be indirectly caused.

Analyze the causes of dropping or tin cracking of circuit board parts

Many friends from circuit board factories often ask: How can BGA be designed to strengthen and improve its strength to prevent BGA cracking? Because some customers complained about BGA cracking on the circuit board, the company must have someone responsible for it.

In fact, it is these senior executives who should be most responsible? The product design is required to be light and thin, as well as to catch up with the schedule. The original 12 month cycle of new products has been shortened to 9 months, and now it is compressed to 6 months. Moreover, the ID has been changing all the time, the schedule cannot be delayed, and the product design is perfect. This group of engineers can only work hard, sell their liver, and everyone is in danger. How did the company culture become like this?

Before we begin to discuss this topIC, we need to understand why BGA is broken? First, aside from the manufacturing problem, it is assumed that all BGA solder balls are well welded and IMC is well generated, but BGA cracks still occur. The main reason should be stress. The reason for this conclusion is that almost all products and parts on the circuit board fall or crack are absolutely related to stress.

The stress sources of circuit board parts falling or tin cracking are as follows:

1. Impact or pressure from outside

Take the mobile phone as an example, the most likely external stress is the force bending in the pocket (iPhone 6plus bending door event), or the impact caused by accidentally falling on the ground.

2. The stress is generated by internal creep

For example, when the circuit board or BGA package undergoes reflow deformation at high temperature, the stress will be released until it reaches a balance point, which may also be the time when the solder ball breaks.

3. The stress comes from the thermal expansion and cold contraction caused by the change of ambient temperature

In some areas, when the product is moved from the indoor heated environment to the outdoor, it will be frozen outdoors in winter; In tropical areas, there is air conditioning indoors, and when you walk from indoors to outdoors, the temperature will change dramatically, not to mention carelessly or intentionally putting the product in the car. The temperature in the sun during the day will rise, and the temperature at night will drop rapidly. The importance of temperature also relates to the different expansion coefficients of different materials. The expansion coefficients of circuit board must be different from that of solder ball, and also different from that of BGA packaging. Just imagine that general roads and bridges will design "expansion joints" to reduce the risk of low thermal expansion and cold contraction of materials, but it seems that electronic materials can only find materials with SMAller expansion coefficients.

PCB manufacturers, PCB designers and PCBA manufacturers explain the causes of PCB deformation and PCB parts falling or tin cracking.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱