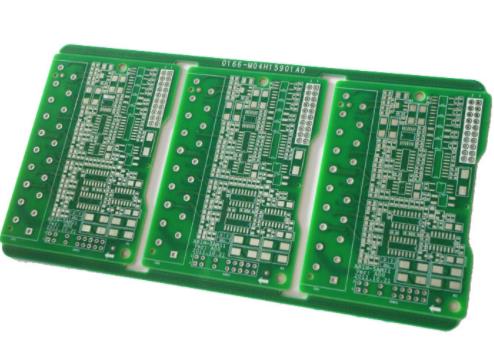

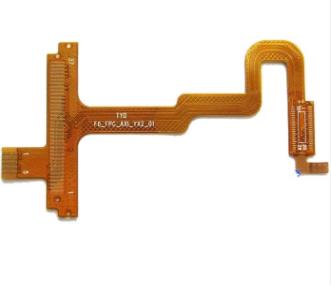

What are the three major factors of FPC welding defects?

What are the three major factors of FPC welding defects that PCB manufacturers, PCB designers and PCBA manufacturers explain to you?

There are three reasons for FPC welding defects:

1. Solderability of FPC holes affects welding quality

Poor solderability of FPC holes will lead to faulty soldering defects, whICh will affect the parameters of components in the circuit, lead to unstable conduction of components and inner layers of multilayer boards, and cause the failure of the entire circuit function. Solderability is the property that the metal surface is wetted by molten solder, that is, a relatively uniform, continuous and smooth adhesive film is formed on the metal surface where the solder is located.

The factors affecting solderability of printed flexible circuit board mainly include:

(1) Composition of solder and properties of solder. Solder is an important part of the welding chEMIcal treatment process. It is composed of chemical materials containing flux. The commonly used low melting point eutectic metal is Sn Pb or Sn Pb Ag, in which the impurity content should be controlLED in proportion to prevent the oxide produced by impurities from being dissolved by the flux. The function of the flux is to help the solder to wet the circuit surface of the soldered board by transferring heat and removing rust. White rosin and isopropanol solvent are generally used.

(2) The weldability is also affected by the welding temperature and the cleanliness of the metal plate surface. If the temperature is too high, the solder diffusion speed will be accelerated. At this time, the solder has high activity, which will rapidly oxidize the Flexible circuit board and the solder melting surface, resulting in welding defects. If the flexible circuit board surface is polluted, the solderability will also be affected, resulting in defects. These defects include tin beads, tin balls, open circuits, poor glossiness, etc.

2. Welding defects caused by warping

flexible circuit boards and components are warped during welding, and defects such as false soldering and short circuit occur due to stress deformation. Warpage is often caused by the temperature imbalance between the upper and lower parts of the FPC. For large PCBs, warping will also occur due to the weight of the board itself. Ordinary PBGA devices are about 0.5mm away from the printed FPC. If the components on the FPC are large, the solder joints will be under stress for a long time as the PCB returns to its normal shape after cooling down. If the components are raised 0.1mm, it will be enough to cause open circuit due to faulty soldering.

3. The design of FPC affects the welding quality

In terms of layout, when the size of FPC is too large, although the welding is easier to control, the printing line is long, the impedance increases, the noise resistance decreases, and the cost increases; If it is too SMAll, the heat dissipation will drop, the welding is not easy to control, and the adjacent lines will easily interfere with each other, such as the electromagnetic interference of the circuit board. Therefore, PCB design must be optimized:

(1) Shorten the connection between high-frequency components and reduce EMI interference.

(2) Components with large weight (such as more than 20g) shall be fixed with supports and then welded.

(3) Heat dissipation shall be considered for heating elements to prevent large Δ In case of defects and rework, the thermal sensor shall be far away from the heat source.

(4) The arrangement of elements shall be as parallel as possible, which is not only beautiful but also easy to weld, and it is suitable for mass production. The flexible circuit board is designed as a 4 ∶ 3 rectangle. The wire width shall not be abrupt to avoid the discontinuity of wiring. When FPC is heated for a long time, copper foil is easy to expand and fall off. Therefore, large area copper foil should be avoided. What are the three major factors of FPC welding defects that PCB manufacturers, PCB designers and PCBA manufacturers explain to you?

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱